Skid steer loaders and compact track loaders can be very versatile dairy tools, but with so many manufacturers and options, it can be difficult to figure out what machine really suits your operation best. Tires and tracks both have their advantages and disadvantages depending on the applications they will be used in.

Skid steer loaders can be great for hard-surface tasks around the farm such as feeding, cleaning manure out of pens and barns, and clearing snow around buildings. Higher top speeds are often available with skid steer loaders than with compact track loaders, which can be beneficial for tasks that require faster transport of materials.

Oftentimes, skid steer loaders can provide a better ride than a comparable compact track loader, but this can be greatly influenced by the specific machine, tire or undercarriage choice and other aspects of the machine’s design.

When it comes to excavation and landscaping-type work, a compact track loader will perform significantly better than a skid steer loader due to the large footprint providing flotation and traction. This large footprint is also why they can lack traction on hard slippery surfaces.

The type of compact track loader can have an impact on the performance and maintenance costs as well. The most common is a rigid all-steel undercarriage that is very durable but can have poor ride quality and traction in some applications.

Some manufacturers (ASV/Terex, Cat MTL, for example) offer a rubber-type undercarriage that can rival a skid steer loader’s speed, comfort and hard-surface traction but with the potential for higher maintenance costs. Compact track loader machines in general will have a higher cost of operation due to higher purchase price, depreciation and maintenance.

Comparing the productivity in your application as well as the machines’ flexibility can help decide which machine type may be right for you.

Choosing a machine with the right physical size, operating capacity and boom design is also an important factor. Vertical and radial booms are the two styles of booms found on skid steer loaders and compact track loaders.

Radial booms lift in an arc, which can provide extended reach partway through the lift path but limited reach at the top. Radial booms are very simple, with fewer moving parts and, in some cases, better visibility. Vertical booms lift in a nearly straight path, keeping the load closer to the machine partway through with more forward reach at the top.

Every late-model skid steer loader/compact track loader uses a universal work tool coupler with options for manual operation or powered operation from the seat. All machines will have a rated operating capacity which is 50 percent of the tipping load for a skid steer loader and 35 percent for a compact track loader.

Higher rated operating capacities often mean a physically larger machine; make sure the machine you choose can still fit in the areas you need to use it.

The machine’s powertrain, hydraulics and cooling should factor into your decision as well. A farm environment can be tough on a cooling system. Study the design of the system, how the air travels, how the coolers are arranged, how easy it will be to clean and if it will do an adequate job keeping itself clean.

If you work in a dirty environment, many manufacturers offer reversing fans; some also offer on-demand fans that only run as often as needed.

Also look at the machine’s serviceability; is there easy access to regular maintenance points? Will it be easy to clean out? Do the cab and boom lift out of the way for easier access? A two-speed option can be very beneficial for increased productivity and resale value.

It can usually be disabled if desired but cannot be economically added to a machine that doesn’t initially have it.

The attachments you will use on the machine will determine if you have a need for high-flow hydraulics as well as an auxiliary electrical control hookup. Self-leveling of the attachment and ride control for the boom can decrease spillage, while the latter can also increase comfort while reducing wear.

The skid steer loader/compact track loader cab is something that has seen a very large change in the past decade; people are spending longer hours running them, so a comfortable, sealed cab with HVAC and a nice seat can be beneficial.

Still, there are tasks that require short periods of operation or communication with ground crews where a cab may not be as beneficial. If you plan to do demolition or brush work, choosing a polycarbonate door versus glass will be beneficial or necessary.

There may be other options that can be beneficial as well, such as keyless start, operator codes with customizable limits, backup cameras and telematics systems for remote monitoring of location, hours, fuel, diagnostics, etc.

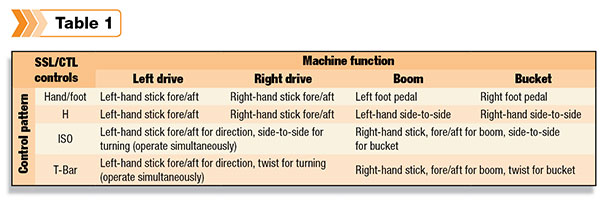

Then there are the controls – a determining factor for some purchases. The patterns of these controls are outlined in Table 1.

In addition to the control pattern, there are three types of controls you may find: mechanical, pilot hydraulic and electric over hydraulic. Mechanical controls will have an actual mechanical connection to the function they operate, while pilot and electrical signal (E/H) operate the function by means of a pilot hydraulic signal, or E/H.

Some manufacturers offer various patterns and types of controls when ordering new, some can convert a machine’s existing pattern, and some have the option of changing patterns with the flip of a switch.

With so many variations and options available in the skid steer loader/compact track loader sector, it can be difficult to find the machine that will work best for your needs. The information here is just one resource; the best way to really understand your needs is to demo multiple machines to get a feel for what suits your needs best. PD

Vinny Endres is a mechanically savvy Wisconsin dairy farmer.