Machines – no farm or ranch can function without them. They save valuable time and are essential to agricultural productivity. They also represent an ever-present danger to the people who operate them. Machines are designed to use power, torque, motion and energy to perform work. They may be powered by power take-off drivelines, hydraulic oil pressure, electrical motors, internal combustion engines or ground traction. Regardless of how machines are powered, they present a number of hazards to those working around them.

There are several dangerous areas that can cause injury, dismemberment and/or the death of the operator. The following are machinery-related hazard areas.

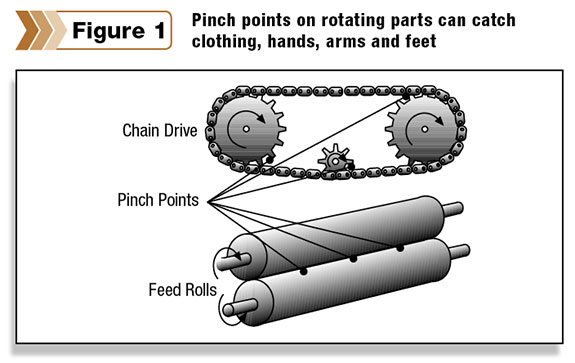

• Pinch points are areas where two or more parts move together with at least one part moving in a circle. The areas where drive belts contact pulleys or sprockets mesh with chains are prime examples of pinch points (see Figure 1) .

• Pinch points are areas where two or more parts move together with at least one part moving in a circle. The areas where drive belts contact pulleys or sprockets mesh with chains are prime examples of pinch points (see Figure 1) .

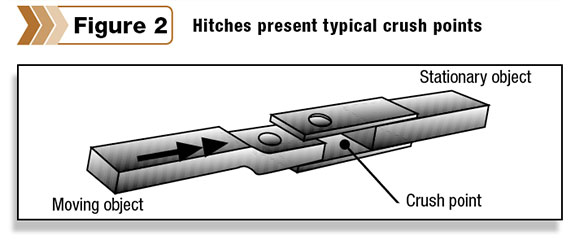

• Crush points are hazards involving two components moving toward each other (see Figure 2) . Examples of crush-point hazards are the raising and lowering equipment with a three-point hitch, components that are moved by hydraulic cylinders and the areas between the tractor and machinery when hitching or turning.

• Wrap (entanglement) point hazards pertain to any

exposed rotating component. Wrap-point hazards include any type of rotating shaft or driveline. PTO drivelines are prime examples of wrapping or entanglement hazards.

• Pull-in point hazards involve mechanisms designed to take in crops or other materials for processing. They include combine headers, windrow pickups, forage chopper headers and grinders.

• Shear and cutting point hazards are areas where two parts move across one another or one moves across a stationary object. Windrower cutter bars and grain augers are examples of cutting and shear points.

• Thrown objects present another type of machine hazard. Metal, glass, wire, sticks or other materials may be picked up by a machine and propelled with extreme force. Rotary mowers are good examples of machines capable of throwing objects.

• Burn point hazards are associated with tractors and self-propelled and pull-type machinery. Hot mufflers, engine blocks, pipes and hot fluids are examples of burn points.

• Stored energy hazards are present in pressurized systems such as hydraulics, compressed air and springs. The sudden or unsuspected pressurization or depressurization of these systems can result in crushing and other types of accidents, depending on the use of the system. High-pressure leaks are also forms of stored energy hazards.

Become a safe operator

Safe machinery operators respect machines for the work they perform and the dangers they present. In order to become a safe machinery operator:

• Learn to operate your machinery properly. Use the operator’s manual as a guide.

• Learn the hazards involved with machinery operation; be proactive and anticipate dangerous situations.

• Be alert at all times when operating machinery. Take breaks and get sufficient food and rest to stay alert.

• Always follow recommended safe practices for operating machinery. PD

—Excerpts from Virginia Cooperative Extension fact sheet. For more information, Click here .