Included in the mix is an average of 8,500 acres of alfalfa hay annually, which is harvested for internal use by the eight family dairies we are responsible for feeding.

In 2009, amid a growing concern for a need to become a more efficient user of water, we decided to begin exploring the use of subsurface drip irrigation (SDI) on our most water-consumptive crop: alfalfa.

Since the installation of our first system on an 80-acre block of alfalfa in the fall of 2009, we have converted roughly 1,100 acres over to SDI for alfalfa and another 600 acres to SDI for silage corn and wheat production. Along the way, we have made many observations and learned many lessons on the benefits alfalfa grown on SDI can have.

Here are some of our observations and results after eight years of SDI implementation.

Site selection and installation

Site selection and subsequent installation of the drip tape can be two of the biggest factors that affect whether or not an SDI system is successful and whether you will reap the benefits of the investment. All of the sites we initially chose for installation have been fields that had been flood irrigated and conventionally tilled for many years prior to the drip tape being installed.

We have also tried to avoid sites surrounded by native habitats or land that has been fallowed for many years. With this site selection process, we have been very successful in limiting the presence of a burrowing rodent population that can potentially wreak havoc on a system and, if not properly controlled, can eventually lead to tape abandonment due to the high labor costs for system repairs.

On all of our systems our philosophy is to monitor, trap and bait the perimeters of the fields very aggressively in hopes of preventing the population from moving into the field. Rewarding employees for their “daily catch” has also provided a bit of an incentive and morale boost for what can sometimes feel like an onerous task.

Also, by selecting sites that have been flood irrigated for many years, we have been able to leach salts from the top profile of the root zone, which could pose a problem for germination of some crops.

Installation

Tape installation is another topic that can be discussed at length. The biggest change we have is the depth at which we place the tape. On our first installations, we buried the tape at a depth of 14 to 15 inches on a 40-inch tape spacing.

While we have had success with these installations, in subsequent years we placed the tape shallower to compensate for the lack of lateral and upward water movement in our sandy loam soils. With most of our tape placed at 10 to 11 inches now, we see a lot less “striping” effect in the first two years of stand establishment.

We have also begun to look at using a larger tape size (.990 versus .875) to increase the uniformity of the system and maximize our distribution uniformity across the entire field. Our tape runs are generally a quarter-mile or longer, and all of our most recent systems have used .990 tape.

The quality of the tape is just as important as the installation itself. If you want to get 10 years or more out of the tape, then you must put a quality product in the ground. We had an experience with one particular system, trying to “cheapen” the price and cut some corners in terms of the quality of the tape we put in the ground.

After about four years, we started to see a large amount of emitter plugging due to soil ingestion, which is essentially fine soil particles working their way into the emitter pathway from the outside. We decided to pull the tape on that system after six years. After identifying the problem and returning to the use of a higher-quality and better-designed product, we have eliminated this problem.

Flushing, charging and running water through the system to allow the tape to occupy its space in the soil profile is also another important factor during installation. If equipment passes are not kept to a minimum before the tape has had a chance to expand and contract and homogenize itself with the soil around it (while running at proper operating pressures), excessive equipment passes, especially turning on headlands or field edges, can lead to compaction of the tape and reduced flow through it.

Irrigation scheduling

In our initial years of managing the irrigation schedule of our SDI systems, we started running anywhere from eight-, 10-, 12- and sometimes 24-hour irrigation sets. With our tape buried at a 14-inch depth, we saw what I call “striping,” where we had considerable growth in about a 20- to 24-inch strip above the tape and then reduced growth in between that appeared to be stressed from insufficient water.

As we began to experiment with different irrigation run times, we found anywhere from three- to eight-hour sets (or pulse irrigation) more frequently gave us the ability to move the water where we wanted it in the soil profile. A 24-hour set actually pushed water downward, instead of pulling the water up through the roots, so pulse irrigation helped with that.

As soon as we take a cutting, before rakes and balers come in, we can hit the crop with a pulse irrigation and keep it in growth mode even before the hay is off the field.

Coupled with the addition of soil moisture-monitoring equipment, we are now able to see the water movement in the profile of our different soils, and this allows us to keep the water in the upper portion of the soil profile during initial field establishment and create a much more uniform stand.

We have also found we consistently end up irrigating almost all of our fields to about 85 to 90 percent of actual evapotranspiration of a grass crop. In the past, we have run schedules where we irrigate to full evapotranspiration – and found, more often than not, we were over-saturating our crop and bringing water to the surface on a regular basis. We did not see any yield increases with irrigating this way and, in fact, began to see an increase in weed pressures due to continual surface wetting that germinated those seeds.

Water savings

Over the past eight years, we have seen about a 25 to 30 percent savings on our water applications for the season. On average, we apply about 41.3 inches of water to our drip-irrigated fields, whereas our flood-irrigated fields generally get an average of 57 inches. With an effective rainfall of about 6.5 inches annually for our area, that puts us right at 47.8 inches of water applied to the crop for the season, which is our target.

Cutting schedules and yield

In general, we try to cut for as much high-test, dairy-quality hay as possible. Seven to eight cuttings per year, starting in late March and running through mid-November, are pretty standard for our operation. About 50 to 60 percent of our production is our target for higher-quality hay. We like to give the hay a bit of a rest in summer months and focus more on tonnage for those cuttings rather than quality.

Since implementing SDI on our ranch, stand longevity has become almost as much of a concern as hay quality. Our goal is to get eight to 10 years on the life of our SDI alfalfa stand, so sometimes quality is sacrificed to maintain a healthy and vigorous stand.

When stand counts for stand evaluations have been compared to flood-irrigated fields, what we have seen is not a dramatic increase in plants or crowns per square foot but a greater amount of stems per crown in that particular square foot.

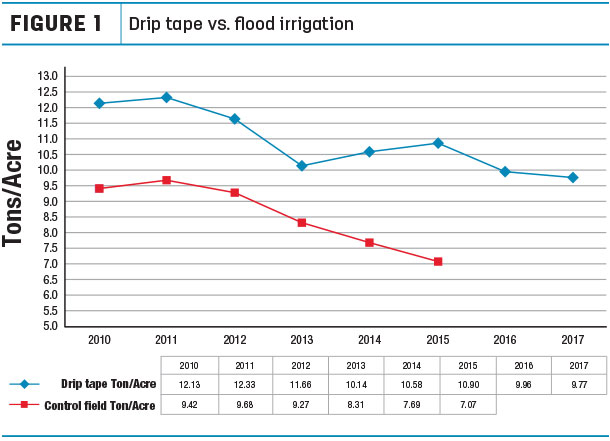

After four years of comparing our first SDI alfalfa field to our control flood field, we saw a 26 percent increase in yield (Figure 1).

After six years of comparison, that number grew to 32 percent increase because the SDI field maintained production and the control field continually declined at a more rapid rate. So far, after eight years of production, our first SDI field has yielded 10.93 tons per acre per year over the course of eight years. ![]()

PHOTO: Nate Ray of DeJager Farms Inc. in Chowchilla, California, discusses the benefits and challenges of subsurface drip irrigation at the Western Forage and Alfalfa Symposium in Reno, Nevada. Photo by Lynn Jaynes.

This presentation was given at the Western Alfalfa and Forage Symposium 2017.