Editor’s note: The following article is the final installment in a series regarding direct tanker loading systems. In the previous two articles, we considered some of the capital costs and marketing criteria a producer should consider when planning for a milk cooling and storage system. In this article, we’re going to compare the annual operating costs of a direct tanker loading (DTL) system to those same costs for a conventional, on-farm bulk tank system.

Annual operating and fixed costs

A general rule of thumb is that the energy required for cooling of a bulk tank is 80 percent of a DTL system. This fact is assumed for the cooling energy cost.

The DTL system does not have a bulk tank to wash. For the purposes of this study, all DTL wash charges are being assumed by someone other than the producer.

In order to calculate the tank washing costs for the bulk tank system, it is assumed the cost of wash water is $2 per 1,000 gallons. On average, it takes 180 gallons per wash for the 700-cow scenario.

The annual wash water cost is 180 gallons per wash x 365 washes per year x $2 per 1,000 gallons = $131 per year. The chemical costs for the 700-cow scenario averages $2.20 per wash, or $803 for the annual cost. In total, the water and chemical costs for the 700-cow scenario is $934 per year for the bulk tank system.

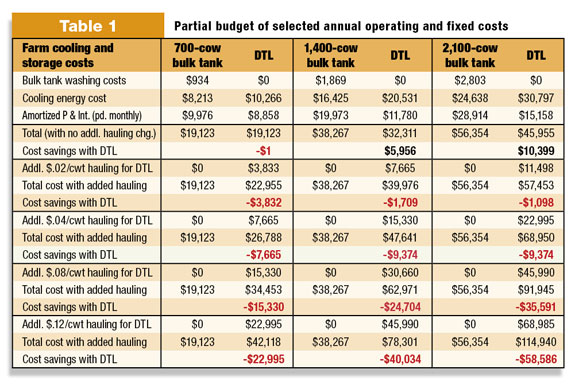

Table 1 summarizes the key quantifiable differences that distinguish the DTL farm from the bulk tank farm by summarizing the relevant annualized costs for these three scenarios. With all the costs now known, it is possible to determine the savings or added cost for the DTL system.

Table 1 illustrates when hauling charges are equal (for the bulk tank farm and the DTL farm), as one goes from the 700-cow farm, to the 1,400-cow farm, to the 2,100-cow farm, the economic benefit of using DTL increases.

However, if the farm is assessed any additional hauling charges for DTL, any benefit would immediately shift to the bulk tank system.

For the 700-cow scenario, annual operation cost is practically the same if there are no additional hauling charges. If a farm of this size is assessed any additional hauling charges, the advantage becomes even greater for the bulk tank system. The table illustrates clearly the impact of any added hauling charge.

For both the 1,400-cow scenario and the 2,100-cow scenario, the annual costs are fairly close if the DTL farm is being assessed an additional $.02-per-cwt hauling charge. However, as hauling charges exceed $.02 per cwt for the DTL farm, the advantage shifts to the bulk tank system for both size farms.

Sorting through the hauling charges

For all the scenarios, the sensitivity analysis in Table 1 demonstrates that the hauling charges have a significant impact on the total annual cost.

It is likely that producers will be considering multiple factors when choosing a cooling and storage system.

By choosing a DTL system, the producer may be focusing on his core competency of milk production and willingly outsourcing the milk storage and related tasks.

However, in order to make the best decisions, the producer will be well served to know to what extent hauling costs will impact the total costs.

In many parts of the country, the line on the milk check titled “hauling” probably does not reflect the actual cost of hauling. In some parts of the country, reduced hauling charges (or “free” hauling) are often utilized as a means to procure producers.

In reality, the actual hauling costs are then camouflaged, somewhere in a reduced gross pay price. Gross pay price is difficult to compare between farms because of multiple component pricing.

In visiting with managers with a number of milk marketing organizations in various areas, it would appear that the most accurate DTL hauling schemes are where the farm is assessed some “fee” for supplying the trailers.

Logically, this fee would reflect back to the cost of leasing the tanker trailers. In most DTL situations, the farm will require at least two trailers on the farm at all times. This would be the rationale for assessing the farm the lease cost for two trailers.

For example, a 2,100-cow DTL dairy farm is shipping three loads per day. It is charged the same rate as a bulk tank farm plus the cost of leasing two trailers.

If those trailers lease for $800 per month each, then the farm is assessed $1,600 per month additional hauling. This would equate to an additional $0.0355 per cwt. The limited hauling data available would suggest that DTL would be a more costly option for all three size farms in this study.

For the producer considering DTL, it is suggested to investigate, carefully, the hauling charge differential between the two different systems. Negotiation of such charges may be well worth the time and effort.

Conclusions

As is so often the case in agriculture, specific solutions for farm milk cooling, storage and transportation is farm-specific. This study is an effort to analyze three hypothetical farms and to draw conclusions based on the given assumptions – fully understanding that in real life, every farm situation is unique.

For example, for the 700-cow, one-tanker-load-per-day farm, a primary question to be asked is: “Does the capital savings at the time of construction (e.g., $11,142) offset the annual difference in operating costs?”

If the farm is being charged an additional $.04 per cwt as a charge for providing trailers, this means the farm would be almost paying an additional $8,000 per year, for the next 20 years.

The critical question for the producer to ask is: “What will be the hauling cost if this farm uses DTL instead of bulk tanks or silos on the farm?” Assuming gross pay price is the same, this is about the only way to determine the actual difference in hauling.

Implications for new construction

The implications for a green-field construction project are many. If a brand new dairy is to be established, the owner needs to consider the difference in capital construction cost, the available markets, the hauling considerations, long-term plans for that site, managerial effectiveness and a whole host of secondary considerations. At a new site, the owner has the luxury of considering all the factors and their potential impact.

Implications for expansion of existing operations

Existing operations will already have some form of milk cooling and storage on the farm. An expansion will have to be a carefully choreographed project that is done in close collaboration with the dairy equipment dealer. If milking is to continue, the service staff will have to work around the milking shifts.

As a conventional, bulk-tank farm expands, a DTL system may be the logical progression in the growth of the business. If the existing tank remains on the farm, it can provide a welcome backup system in the event of refrigeration problems or in the event empty trailers can’t be delivered to the farm. This value needs to be weighed against the cost of retaining the tank assets.

Conclusions and long-term goals of the producer

At first glance, most producers may be inclined to assume that the DTL system is simply less capital-intensive because no bulk tanks are purchased.

While the capital cost savings are significant, the savings are still a relatively small proportion of the overall facility expenditure. The owners’ long-term goals should be carefully weighed and balanced against the immediate capital cost savings.

Regarding all the factors previously discussed, it appears that the DTL system becomes more competitive as the farm gets larger. Another suggested area for further study would be the use of silos and non-refrigerated tanks in concert with glycol plate chillers. PD

References omitted due to space but are available upon request. Click here to email an editor.

PHOTO

In visiting with managers with a number of milk marketing organizations in various areas, it would appear that the most accurate DTL hauling schemes are where the farm is assessed some ‘fee’ for supplying the trailers. Photo courtsey of PD staff.