More dairy nutritionists are embracing the practice of amino acid balancing. For those that have, the economic rewards have been excellent. This is particularly true for producers paid the Class III component formulas – where milk protein continues to be the most valuable, followed by milk fat and other solids. Payments for milk protein make up more than 50 percent of a producer’s milk check and milk fat accounts for about 35 percent.

While it seems clear that, in many market segments, the advantage belongs to those who can produce and process the most components most efficiently, some still have apprehension toward amino acid balancing.

We continue to hear comments such as “responses are small and inconsistent,” “production isn’t high enough,” “I tried it already and it doesn’t work,” “I will lose production if I lower dietary protein” and “protected amino acids are expensive … feed costs are important.”

Our industry is experiencing a paradigm shift in how we balance diets. Protein supplements have doubled in price, so the high crude protein diets of yesteryear (put in place as insurance for high production) are being replaced with lower crude protein diets. Also, the “lead factor” or “safety factor” to ensure peak performance is shrinking.

Some of the challenges expressed by feed industry personnel in a 2006 Cornell University survey about lowering crude protein levels were consistency and quality of feed delivered to the cow, herd grouping and ration strategies, accuracy of forage sampling and analysis, accuracy of formulation tools and “real” farm information from herds with lower crude protein rations.

As a followup to the last point, Cornell scientists reviewed data from 25 herds that already fed lower crude protein (14.3 to 16.5 percent) rations with milk production between 80 to 95 pounds per day.

They concluded that lower crude protein rations can be fed in commercial herds and will support high levels of milk production. They also pointed out a wide variation in the amino acid balance in these herds. In most cases, this appears to be an area of opportunity and future consideration.

The future is today. Advances in nutrition research, feed analysis, high-quality protein/amino acid supplements and ration formulation models have allowed dairy nutritionists to increase the precision of diet formulation.

Through amino acid balancing, we target the needs of rumen fermentation to maximize microbial protein and lower RUP feeding. This means we can achieve the amino acid requirements of the cow with a minimum amount of dietary crude protein.

Our field experience consistently shows similar results to the research. Improved lysine and methionine nutrition has resulted in increases in milk yield and increased concentrations and yields of milk protein and milk fat, often on less dietary RUP.

We have eight years of experience in amino acid balancing with rumen-protected methionine. In the last 18 to 30 months, several rumen-protected lysine products have become available to the industry.

These products are formulated by their manufacturers to contain lysine in a matrix, which offers protection and allows for a significant level of lysine to be delivered to the small intestine for absorption by the cow.

How does that change our thinking when balancing for amino acids? Not a lot. These products simply have given us a tool to accomplish the goals we were unable to meet before they became available.

Prior to rumen-protected lysine sources, we were limited in our ability to maximize lysine delivery. Traditionally, lysine was almost always delivered by the use of blood meal and fish meal. While these animal products contain the highest percentage of RUP lysine, they can limit rumen fermentation because the protein sources are tightly formed.

By increasing these in the diet, we were taking away degradable protein from the rumen bacteria. By using a rumen-protected lysine source, we can deliver high levels of lysine to the cow for her production needs while lowering – or in some cases eliminating – the RUP from animal byproducts.

Because the rumen-protected lysine sources are very concentrated as compared to animal byproducts, formulating with them allows for more fermentable carbohydrate sources to be included in the ration, leading to more microbial protein production.

In most cases, we have been filling this “space” created in the ration with corn silage, corn grain and high-fiber byproducts – the ingredient used depends on the needs of the cows and the goals of the dairy.

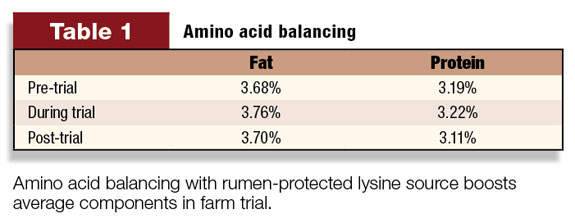

We began formulating with the rumen-protected lysine products in the late summer of 2010. In December 2010, we ran a field trial on a 300-cow dairy averaging 87 pounds of milk, 3.68 percent fat and 3.19 percent protein. These cows were on an amino acid-balanced diet with

approximately one pound of blood meal and 0.20 pounds of fish meal being fed.

In this trial, we replaced 0.50 pounds of blood meal with a rumen-protected lysine source and expeller soybean meal.

The expeller soybean meal was included because we were concerned about magnitude of the decrease in crude protein level of the ration. In the ration, dietary crude protein was decreased from 16.9 percent to 16.3 percent. We saw no difference in milk production and possibly a slight improvement in percentages of milk fat and milk protein. During the winter of 2011, we conducted similar trials with similar results ( seeTable 1 above ).

Since that time, we have been formulating more and more rations with these products. Again, in most cases, we are now filling the “space” created in the ration with carbohydrate sources rather than protein sources.

We are allowing ration crude protein levels to decrease to the 15.5-to-16-percent range with no negative impacts on performance.

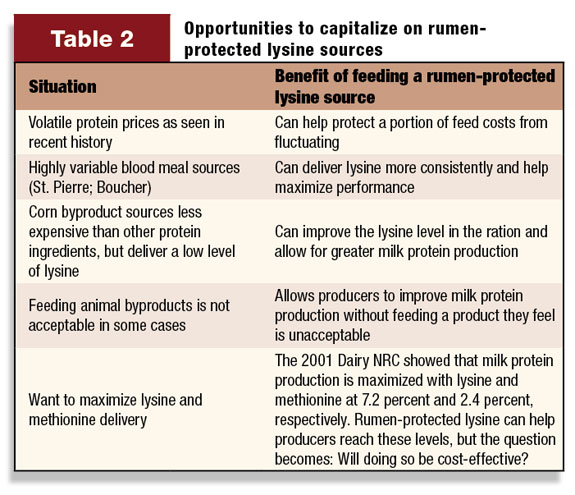

This is just one strategy we’ve used to capitalize on these products for improved components. We still see many other areas of opportunity to utilize them. See Table 2 for other potential strategies. PD

Spence Driver is dairy technical services manager and Stacy Nichols is dairy technical specialist for Vita Plus Corporation.

References omitted due to space

but are available upon request.

-

Spence Driver

- Dairy Technical Services Manager/li>

- Vita Plus Corporation

- Email Spence Driver