Editor’s note: This is the first of four articles explaining producer payment systems for milk in the U.S. The vast majority of producers in the U.S. are paid by one of the three systems – the Federal Milk Marketing Order component payment system, the California payment system and the Federal Milk Marketing Order advanced payment system.

These systems share a common theme in that the payment is calculated based on the wholesale price of products produced from milk.

Structured payment systems like the Federal Milk Marketing Orders have been in place for over a century and continue to dominate producer payment for milk in the U.S. The last major revision of the Federal Milk Marketing Order system was implemented in January 2000. This system controls payment for two-thirds of the milk produced in the U.S.

The payment systems were developed because milk is essential to health. It was therefore controlled to ensure an adequate supply of fresh milk. Essential to ensuring an adequate supply of fresh milk, producer milk pricing processes were developed to help producers and processors survive financially.

In 1937, California was able to convince the courts their milk supply and usage were not interstate commerce. California was therefore excluded from the Federal Milk Marketing Orders and was allowed to manage their own payment system. Today, California would have difficulty proving their milk is intrastate, but the system still stands. However, there is serious effort under way to bring California producers back into the federal order system.

More recently, other events have reduced the federal government control of pricing. In May 2004, the Western Federal Milk Marketing Order was disbanded. In this area, milk can be priced by any method agreeable between the producer and the processor. In reality, many of the payment systems are similar to the federal milk order system that existed previously.

Another shifting pattern that can be significant is de-pooling. In some years as much as 20 percent of the milk in the Upper Midwest is “de-pooled,” or removed from the federal order pricing requirements. De-pooling takes place when Class III milk for cheese is priced higher than the weighted value of the other three classes of milk.

Consumption of dairy products has changed materially over the last 50 years. Consumer eating and drinking habits have significantly changed. Per-capita fluid milk consumption has dropped by 50 percent since 1945. Per-capita butter consumption has dropped by 70 percent since 1930.

Cheese per-capita consumption has increased 300 percent since 1970. Improved transportation and the dominance of processed milk products that contain less water have reduced geographical barriers, and the U.S. dairy industry is now in transition to be an international business.

These consumption changes have also changed the nature and geographical landscape of milk production. For instance, Florida, which is a fluid milk market, shrinks every year – while Wisconsin, where more than 80 percent of the milk is used for cheese, continues to grow.

Florida producers are paid on the advanced system, and Wisconsin producers are paid on the component system. The changing consumption patterns have reduced the amount of milk paid on the advanced system and increased the amount of milk paid on the component system.

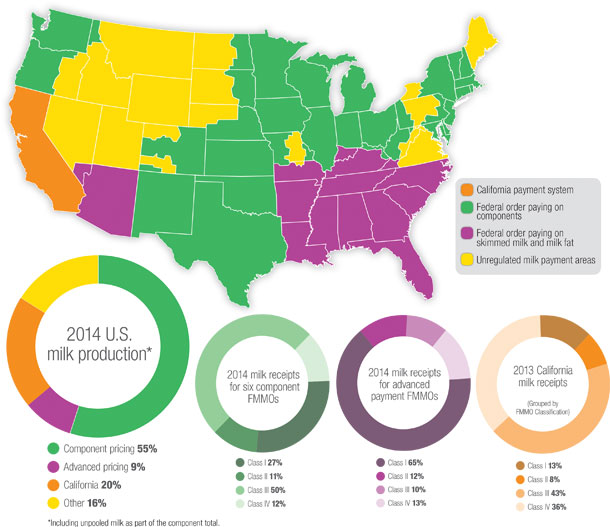

The chart above shows geographically where milk is controlled by which system. The six orders paid on components are the Pacific Northwest, the Upper Midwest, the Central, the Southwest, the Mideast and the Northeast. The orders paid on hundredweights of skimmed milk and milkfat (the “advanced” system) are Florida, Southeast, Appalachian and Arizona – Las Vegas. California is the only state that has their own system.

Click here or on the image above to open in a new window at a larger size. (PDF, 3MB)

U.S. milk production by payment system is shown in the pie charts above. The federal order component payment system is the largest of the three structured milk payment systems, and it is continuing to grow. The federal orders paid on the advanced system decrease in percentage each year.

As mentioned above, in terms of milk production, the largest payment system by far is comprised of the six orders paid on the component payment system. These orders enjoy production of milk for the growing milk categories like cheese and yogurt. Producers in these orders are paid primarily on pounds of milk protein, pounds of milkfat and pounds of other solids.

The water content of milk has no value in this system. Prices for these are determined by formula at the end of the month. Class III milk for cheese is the largest milk category in these orders, and the payment system is designed to create the right incentives for milk appropriate for cheese manufacturing.

Milk usage in the large component payment system is shown below. Class III (milk for cheese) is the dominant class and growing. Class I (milk for fluid milk products) continues to decline.

The four federal milk orders paid on the “advanced” system, paying for hundredweights of skimmed milk and butterfat, provide primarily fluid milk for drinking. The system is called the “advanced” system because prices are announced in advance of milk production.

The fluid milk category is declining, and so is the dairy business in these orders. The payment system is designed to support the primary end products: fluid milk. The slice designated as Class IV (used for nonfat dry milk) is almost totally from the Arizona – Las Vegas order.

California has the advantage of being on the coast and enjoys a very healthy dairy export business. Nonfat dry milk has seen considerable growth in the last decade as exports were expanded. Their system is primarily a component payment system based on milkfat and all other solids. In other words, this system pays the same for lactose as it does for milk protein.

Therefore, the largest cheese producers pay a separate premium incentive for milk protein they need for making cheese. Nonfat dry milk has grown to be a significant usage of California-produced milk, and the majority of this is exported. The chart below shows California 2013 data, as the 2014 data is not yet fully available.

The Federal Milk Marketing Orders define milk in four different classes based on their usage. California defines six different classes of milk. In the charts below, the six California classes are collapsed into four to be comparable to the Federal Milk Marketing Order classifications.

In forthcoming issues, the formulas used in these payment systems and some of the differences within the orders, will be reviewed. The concept for the payment formulas is pretty standard in all the systems.

For example, the price of milkfat is determined by the wholesale price of butter less the cost to churn the milkfat into butter. However, some idiosyncrasies, such as the payment for a lower somatic cell count used in just four of the six component orders, adds complicating detail. PD

Click here to read the second article "How the FMMO's component payment system works"

Click here to read the third article "The Federal Milk Market Order's advanced payment system"

Click here to read the fourth article "California vs. FMMO milk pricing"

-

John Geuss

- John Geuss Consulting

- Email John Geuss