Every dairy needs bedding. The source, cost, transportation, storage and function of bedding all are considerations when choosing a herd’s best option. So, too, is the way manure is managed within the bedding system.

Many farms are choosing to adopt “green” or “fiber” bedding, creating an integrated feed/manure/bedding system that is self-sustaining within the dairy operation.

Going green

Fiber bedding is often referred to as green bedding. The term green bedding can be a misnomer, as it is not green in color. Nor does the expression have anything to do with an environmental philosophy. Rather, it is an indication that the fiber in the bedding has not been run through a pathogen-kill process – like composting or anaerobic digestion – prior to its processing through a separator and being used.

Think of the term as similar to green lumber (freshly cut, unseasoned wood) or greenchop (fresh forage that is fed immediately and not fermented as silage).

Fiber bedding captures the undigestible lignin component of plants in a reusable form that is extracted out of manure and recycled into bedding. This manure fiber is removed by processing fresh manure using a mechanical separation system. The bedding often is used the same day as processing or stored for no more than a few days.

Extracting the longest possible fiber from manure is an important consideration in fiber bedding production. Because most herds feed TMRs and not long-stemmed hay, manure fibers are relatively short to begin with. A roller press-style separator can protect the fiber length more effectively than a screw press-style separator.

Is it worth it?

Adopting fiber bedding requires an up-front investment in processing equipment, plus it creates another routine task that must be regularly managed on the dairy. But manure must be handled in some fashion on every operation, plus there are a number of upsides to fiber bedding, including:

- The system provides a consistent source of bedding that does not vary in cost or availability.

- Less time is spent sourcing and hauling bedding.

- Manure hauling expenses are reduced.

- Fiber bedding is easier to handle than some other bedding types, leading to less wear and tear on equipment.

- Less storage space is needed compared to sawdust, straw or sand.

- Potential for additional revenue exists from selling excess fiber.

A comprehensive Cornell University study showed that, compared to other bedding sources, dairies bedding with manure solids saved an average of 12 cents per hundredweight of milk produced. That calculation included the cost of the processing equipment. As with many capital purchases, the larger the herd size, the more economical this investment will be.

It is likely that a farm’s existing manure collection system can be retained when adopting fiber bedding. Whether manure is gathered via skid loaders, alley scrapers, a flush system or vacuum tanks, it is possible to process it into bedding. In new construction settings, the choice of alley scrapers would most likely be optimal. Mechanical scrapers keep alleys cleaner and dryer, and reduce the load of fresh manure cows carry into stalls on their feet.

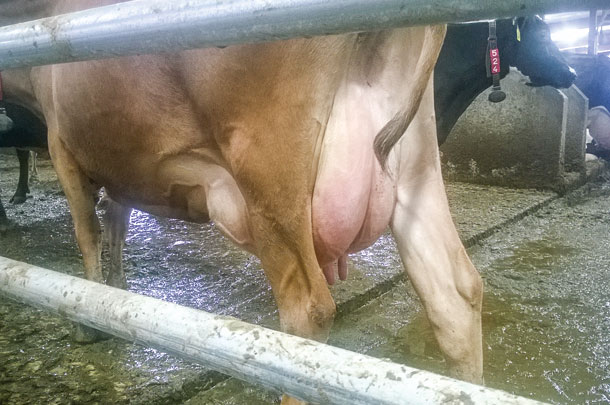

Fiber bedding can be used in both mattress and deep-bedded stall management. Mechanical bedding spreaders work well for distribution. As with any type of bedding, stalls need to be maintained on a regular schedule to clean out, replenish and level bedding to create a clean, dry, comfortable resting surface for every cow. When this is done well with fiber bedding, producers attest to the fact that they have never had cleaner cows with any other bedding type.

What about bacteria?

The first thought many producers have when considering bedding with materials that were a component of manure is that it could be a risky proposition from a bacteria standpoint. Bacteria are part of the natural flora of everyday life, including the life of a cow. There are good and bad bacteria, and they coexist and balance one another out.

Problems occur when the bad bacteria overwhelm the good in a dirty environment. But trying to create a sterile environment can be equally troublesome because the absence of good bacteria can allow the bad bacteria to replicate faster.

When comparing many different types of bedding, Cornell researchers found bedding material that contains very low initial bacteria levels fostered faster bacterial growth than separated fiber bedding. The researchers attributed this finding to the fact that the near-sterile bedding provided no competition of good bacteria to the bad bacteria supplied by cows’ urine and feces.

The key to maintaining bacterial equilibrium is good barn and animal hygiene, of which routine bedding maintenance is an important element. The initial bacterial load in the bedding is not nearly as important as keeping it refreshed and maintained. Overpopulation and poor ventilation also can contribute to harmful bacterial overload and need to be abated for successful use of green bedding.

Bacterial growth in fiber bedding also can be minimized via particle size. Maintaining larger particles creates less surface area per volume of bedding, creating less opportunity for bacterial growth. Larger particles also allow the bedding to dry more rapidly. A dry matter content of 30 percent or higher is recommended for fiber bedding.

When housing conditions and particle size are managed well, research studies have shown herds that have switched to fiber bedding actually have lower bulk tank somatic cell counts than those using other bedding types.

Words of caution

While fiber bedding can be an efficient and economic management system, it won’t solve pre-existing problems on any dairy. If stall maintenance, barn cleanliness, ventilation or stocking density are lacking before adopting fiber bedding, they will continue to cause problems afterward if they are not rectified.

Maintaining particle size also is an important air-quality issue for both animals and workers. If manure solids are too finely processed, they can create dust from both distribution equipment and ventilation fans.

Finally, fiber bedding is not recommended for herds struggling with vertical diseases like Johne’s disease.

If you’re considering green bedding, consult your herd advisers to discuss how this bedding system could contribute to cleanliness, cow comfort and economic viability in your herd. PD

References omitted due to space but are available upon request. Click here to email an editor.

Photo 1: This roller-processed fiber bedding displays a desirable, light color and excellent dryness, with no moisture “weeping” from the pile.

Photo 2: A cow in a fiber-bedded barn, displaying exceptionally clean udder, teats and hocks. Photos provided by GEA Farm Technologies.

-

Jeramy Sanford

- Field Manager and Manure Specialist

- GEA Farm Technologies

- Email Jeramy Sanford