The goal in feeding a TMR is to minimize the number of hours during the day when rumen pH is below 5.8. Low rumen pH inhibits rumen microbial growth and causes subacute rumen acidosis (SARA).

Feeding rations that contain high levels of fermentable carbohydrate, too little effective fiber or encourage slug feeding may result in SARA. SARA symptoms may include roller-coaster dry matter intakes, inconsistent manure, bubbly manure, reduction in cud chewing and a low milk-fat test.

Cows may slug feed if the TMR is not mixed consistently, resulting in extended periods of low rumen pH. The ideal TMR is mixed so that every bite is the same, thus reducing the chance of slug feeding.

Well-mixed TMRs also encourage cows to eat several small meals during the day, reducing the risk of SARA even further.

In February 2013, our team of nutritionists conducted a case study to prove the importance of consistency in the TMR mixing process. We visited a 300-cow Holstein herd in northern Virginia and evaluated the cows, facilities and manure.

We found an inconsistency in the manure, with some being too stiff and others being too loose. The cows were digging holes in the TMR with their muzzles, indicating that they were sorting the TMR.

When cows sort feed, they tend to eat larger meals of highly fermentable carbohydrates, which increases the likelihood of SARA. Even with our concerns about sorting, the tank average was 75 pounds of milk with a 4.0 percent fat test.

The herd ownerâs goals were to increase milk per cow and improve hoof health, both of which are impacted by SARA. This herd appeared to have at least a moderate risk of SARA and further investigation was warranted.

We enlisted the help of Diamond V staff to assist us in conducting a TMR audit. To determine the consistency of the TMR mixing, we pulled 10 samples of fresh TMR along the length of the feedbunk just after it was delivered.

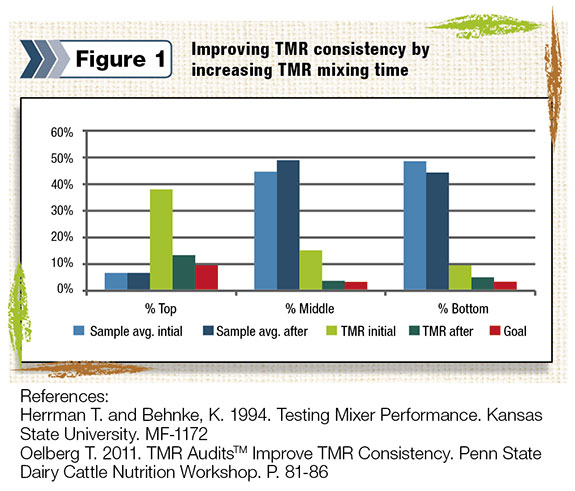

These 10 samples were then separated using the Penn State particle separator. The results are shown in Figure 1 .

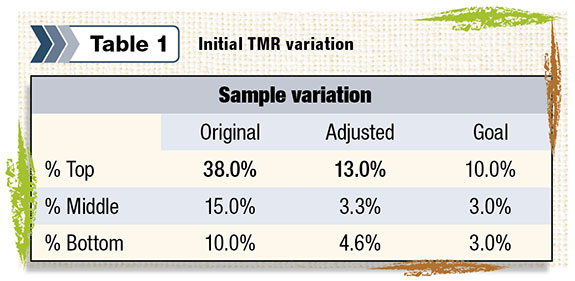

We found considerable variation in particle distribution along the length of the feedbunk, and observed a variation of 38 percent, 15 percent and 10 percent, respectively, between the top screen, middle screen and pan.

The goal for TMR variation is 10 percent, 3 percent and 3 percent. It is possible to see variation as low as 1 to 2 percent.

The high level of variation in the TMR on this ration indicated that the risk of SARA was significant.

While watching the TMR mixing process, it was determined that the actual mixing time, once all the ingredients were loaded in the TMR mixer, was less than five minutes.

Kansas State University research has shown that when variation is high in feed mixes, increasing mixing time is an effective means to reducing the variation in the mix. So we recommended increasing the TMR mixing time to a minimum of six minutes.

Research from 2011 has shown that adding liquid to a TMR can have a significant impact on maintaining TMR consistency.

On this farm, we recommended increasing the amount of water added to the TMR to make the mix more consistent and more difficult for the cows to sort.

The herd owner agreed to increase the mixing time. We repeated the process of measuring TMR mixing consistency the next day. The results are shown in Figure 1.

As we looked across the samples from the top screen, it was apparent that there was more consistency in the mix as it is fed out along the feedbunk.

Table 1 shows that the variation was greatly reduced and came closer to the goals.

Simply increasing the mixing time on the TMR had a huge impact on the consistency of the feed delivered to the cows.

In the future, when the herd owner takes the additional step of adding more water to the TMR, the variation in particle size distribution will likely approach the goal levels.

Our systems of ration formulation have become quite sophisticated. On paper, we can balance rations down to the gram for many nutrients, and we can carefully balance carbohydrates and fiber to reduce the risk of SARA.

However, what matters most is what the cows actually consume and the consistency of the diet individuals in the herd consume. It is easy to overlook the TMR mixer and TMR mixing process when troubleshooting problems in the herd.

This case shows that a minor adjustment in the TMR mixing process can have a significant impact on the ration delivered to the cows.

In the original sample, significant variation in the particle distribution of the TMR is indicated by the high variation among 10 samples that were pulled from the feedbunk and separated with the Penn State particle separator. After adjusting the mixing time, the variation is reduced and approaches the goals.

References omitted due to space but are available upon request. Click here to email an editor.