A list of risk factors for the most common infectious foot lesion, digital dermatitis (DD, also known as hairy heel warts, Mortellaro’s disease), includes multiple aspects related to the cow, the farm’s management and environment.

Focusing just on the latter two, from suboptimal footbath protocol, footbath design and poor external biosecurity to slurry, wet and muddy conditions, the type of manure scraping system and scraping frequency, there are many factors to consider. So why are hygiene-related factors so important?

Because, as with many other infectious diseases, manure and slurry can be a source of infection by DD-associated bacteria. However, we can limit the survival and growth of these bacteria by providing an environment as clean and dry as possible. Although it is true there are still many questions regarding the exact route of DD transmission, let’s work with what we know so far.

What research tells us about manure scrapers

From our research in North America and studies in Europe, we know farms with poor leg cleanliness have higher prevalence of DD and lower DD cure rates compared to farms with good leg cleanliness. In Canadian freestall herds, cows in barns with automatic scrapers had 2.6 times the odds of having DD compared to cows on farms with manual (e.g., skid steer) scraping systems.

This implies automatic scrapers are associated with increased DD prevalence. However, there are conflicting results regarding scraping frequency and levels of DD. In Ontario freestall herds, a scraping frequency of more than seven times per day was associated with higher DD compared to less than seven times per day.

The opposite was found in Denmark, where frequent scraping (more than eight times per day) was associated with lower DD. Similarly, in Canadian automatic milking systems, frequent scraping was associated with less lameness.

Other U.S., Swiss and Dutch research on manure scrapers has focused on their effects on behavior, stumble incidents and occurrence of injuries. In regard to behavior, direct confrontation with a scraper (i.e., seeing it coming) seems less stressful for cows than situations where they can anticipate the running scraper but can’t assess its approach (i.e., cows locked in headlocks; Figure 1).

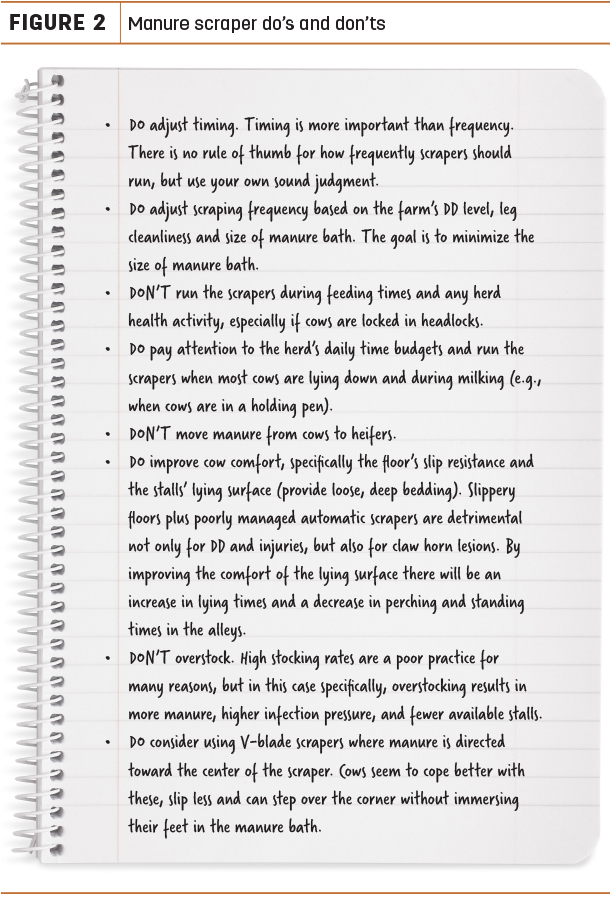

If scraping takes place during main feeding periods, it disrupts the herd’s feeding behavior (i.e., number of feeding bouts and duration of nighttime feeding). Also, a low V-blade scraper seems to cause fewer behavioral disturbances than a higher straight-blade scraper.

In regard to stumbles and injuries, 94 percent of the incidents of tripping or stumbling result from direct contact with the scrapers. And in the northeastern U.S., cows on farms where manure was removed using automatic scrapers were twice as likely to have severe hock injuries compared to cows on farms with other manure removal systems.

In a nutshell, automatic scrapers clearly have a negative effect on foot health and behavior. However, they are widely used (approximately 30 percent of U.S. dairy operations have them) because they save labor and resources. So in spite of the limitations of automatic scrapers, let’s aim to provide cows with the cleanest, driest and most comfortable walking surfaces possible.

How do we evaluate floor cleanliness?

By looking at the cow. Use any of the many scoring guides available online to assess leg cleanliness. High scores usually mean “dirty” and are based on the degree of contamination with dried, caked manure found on the outside of the leg.

We know, through benchmarking, freestall herds with the least contamination have approximately less than 15 percent of cows with dirty legs. So if a high percentage of cows have dirty legs, adjustments in scraping frequency should probably be made.

Another more anecdotal way of assessing if scraping frequency should be adjusted is evaluating the size of the “manure bath” in front of the scraper. This should be less than one stride for a cow to walk over.

Automatic scrapers – management done right

There are several ways we can optimize the use of automatic scrapers by minimizing the size of the manure bath and reducing the disturbances it causes to cows. Figure 2 shows solutions for new and existing facilities based on management and design.

Solutions for new barns:

- Give cows enough room to avoid or easily confront scrapers by designing wide alleys (13 to 15 feet for feed alleys) and multiple crossovers (one every 20 to 25 stalls).

- Put in a guiding groove for the scraper. According to Jeramy Sanford from GEA, the groove acts as a guide for either a chain or a cable, holding the scraper straight down the alley for more efficient cleaning.

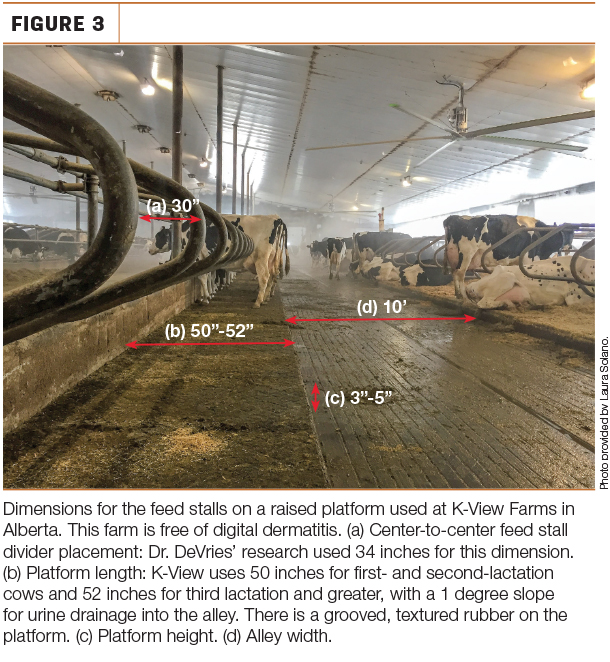

- Put feed stalls on a raised platform (Figure 3). Twelve years ago, Trevor De Vries reported feed stalls reduced aggressive behavior and competition at the feedbunk, reduced time spent standing in the feeding area while not feeding and increased feeding time.

This, in combination with a raised platform for cows to stand on while eating, allows the scraper to run behind the cow without disturbing feeding and provides a clean, dry floor to stand on while eating. The feed stalls keep the cows positioned straight so manure falls in the alley.

Figure 3 is from K-View Farms in Alberta and shows the dimensions they are currently using. K-View went a step further by adding a grooved, textured rubber on the platform.

Several years of foot lesion reports from K-View Farms show they are one of the very few (5 percent) farms in Alberta free of DD. Gregg Debbink, one of the owners, comments the current platform is 3 inches high, but he recommends making it slightly higher (5 inches) as manure builds up at the end of the scrape alley.

He would have a 1-degree slope in the platform so urine drains to the alley and the platform stays cleaner and drier.

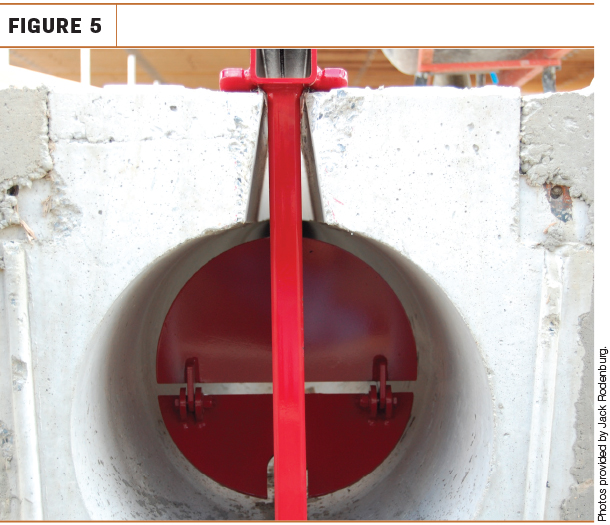

- Tube scraper system: This consists of a prefabricated tube installed underneath the manure alley with a 2-inch-wide slot opening in the top, an alley slightly sloped from the edges into the center and a V-shape scraper (Figure 4).

The slope and shape of the scraper directs manure liquids toward the center of the scraper. This results in liquids being collected by the underground tube (Figure 5) rather than dragged through the length of the alley, minimizing the manure wave.

The slope and shape of the scraper directs manure liquids toward the center of the scraper. This results in liquids being collected by the underground tube (Figure 5) rather than dragged through the length of the alley, minimizing the manure wave.  According to Jack Rodenburg from DairyLogix, additional benefits of these type of scrapers are: They have been adapted to clean in both directions, resulting in fewer passes and cleaner alleys, and there is less cable/chain wear, as it does not run over the concrete floor.

According to Jack Rodenburg from DairyLogix, additional benefits of these type of scrapers are: They have been adapted to clean in both directions, resulting in fewer passes and cleaner alleys, and there is less cable/chain wear, as it does not run over the concrete floor.

In conclusion, there is evidence automatic scrapers have a negative impact on foot health, injuries and behavior. However, it is also possible to achieve zero prevalence of DD on farms that use scrapers properly. Improvements can be made in the way, time and frequency scrapers are used.

For new constructions, there is plenty of potential in combining feed stalls on a raised platform with a tube scraper system. Considering the price of lameness, investing in good design and management can be cost-effective. ![]()

FIGURE 1-3: Photos provided by Laura Solano.

FIGURE 4-5: Photos provided by Jack Rodenburg.

-

Laura Solano

- Dairy Cattle Extension Specialist

- Farm Animal Care Associates

- Email Laura Solano