Lighting often represents one of the best opportunities to reduce electricity use on dairy farms, and lighting retrofits typically have shorter paybacks than other energy-efficiency upgrades. Over the last decade, light-emitting diode (LED) lighting has experienced rapid growth and adoption, with prices dropping 90 percent.

If you haven’t already jumped on the LED bandwagon, it’s important to know the basics of LEDs and how they apply to your farm. Read further to learn more about how to reduce your lighting costs and ensure you pick the best lighting for the job.

About LEDs

LEDs account for over half of U.S. lighting sales, and the U.S. Department of Energy predicts LEDs will account for 84 percent of sales by 2030. Within the dairy sector, the transition to LED lighting has also been accelerating, with many farms converting old fluorescent or high-intensity discharge lamps to LED fixtures. The main advantages of LED lighting are their efficiency (or luminous efficacy) and their long useful life.

These characteristics result in significant energy savings over the life of the fixture (approximately 50 to 75 percent less energy than standard lighting fixtures such as incandescent, mercury vapor, metal halide, high-pressure sodium and halogen). Depending on the type of LED and the length of time the lighting is typically used, most LEDs have a simple payback between one and five years.

LEDs also last much longer than alternative lighting, reducing your labor costs to replace bulbs. Unlike many other types of lighting, LEDs do not contain hazardous mercury. Most LED fixtures are dust- and moisture-resistant, and there is generally no need to enclose them in vapor-proof enclosures.

To further reduce your initial investment, exterior LED fixtures can be purchased as a retrofit kit to fit into an existing housing/assembly for a traditional light, although we generally recommend replacing the entire fixture. This will avoid premature failure of the fixture due to degraded existing fixture components or compatibility issues.

Lighting level considerations for dairies

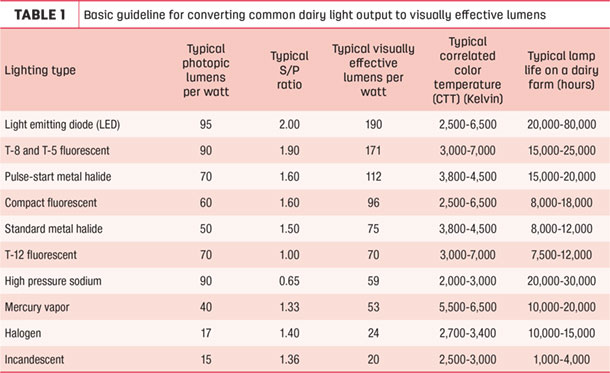

When considering a lighting energy-efficiency project, it is important to evaluate the quality of light and visually effective lumens of the light source you are choosing. Evaluating lighting can be confusing since efficacy is typically measured in lumens per watt, as determined by a conventional light meter.

These meters only account for photopic lumens, which is not representative of how the human eye perceives light in all situations. As a result, lighting manufacturers and designers often use a correction factor called a “scotopic/photopic ratio” (S/P ratio) to more accurately represent light brightness as we perceive it.

Table 1 provides a basic guideline for converting common dairy light output to visually effective lumens.

Visually effective lumens can be used as a basic approximation of the efficiency of different lighting alternatives. In general, LED, linear fluorescent (T8 and T5) and pulse-start metal halide lamps are the best choices for applications on dairy farms.

When planning new lighting projects, it is important to consider the lifetime costs of fixtures, which includes replacement materials and labor for fixture components in addition to luminous efficacy.

Lighting to improve milk output

In addition to reducing energy costs, certain barn illumination techniques have also been shown to improve milk output in some cases. The most common method for improving milk production with lighting is long-day lighting, also known as photoperiod control.

Studies have indicated consistently exposing cows to approximately 16 to 18 hours of light and six to eight hours of darkness per day can result in a milk production increase of 5 to 16 percent.

Several LED lighting manufacturers have developed LED fixtures optimized for long-day lighting for dairy farms, which can make the transition to this lighting schedule easier and provide just enough light to dairy operators during the dark period while still achieving the desired production increase.

Other tips to reduce lighting energy use

No matter what type of lighting you have on your farm, you can implement immediate low-cost steps to reduce the cost of your lighting:

- Replace inefficient light bulbs with higher-efficiency types. See Table 1 for suggestions.

- Consult third-party listings, like the Design Lighting Consortium, to evaluate LED lighting options.

- Turn off lights when not in use.

- Utilize daylight when possible.

- Consider the use of motion/occupancy sensors in areas that do not require constant lighting.

- Consider installing timers or photocells to ensure outdoor lights only operate outside of daytime hours.

- Install dimmers to enable adjustments in the intensity of light to fit current lighting needs.

- Consider careful barn design and layout, which can help maximize light distribution, reducing overall electricity needs.