My professional experience has put me in front of many cattle owners and farm managers skeptical of silage inoculants.

Many saw it as paying for pixie dust – unsure of what it could really offer. I understand their skepticism, but in the past few years, considerable research indicates silage inoculants are effective at reducing nutrient loss and increasing animal performance.

Industry leaders advise to treat every ensiled crop with effective silage inoculants manufactured by a reputable company whose product is supported by university research.

Still not convinced? OK, let’s break it down and talk about what’s happening to your feed once it’s ensiled and the threat Mother Nature imposes.

Fundamentals of fermentation

Making silage is a fermentation process where bacteria use sugars to form organic acids that lower pH and preserve the forage.

The crop is at its highest nutrient level when first chopped, so it’s a race against time to achieve fast fermentation.

The bacteria will only go to work once the presence of oxygen has been eliminated, therefore making a producer susceptible to nutrient and dry matter losses if his forage isn’t ensiled properly.

This doesn’t include the loss of time, energy, water and other production and harvesting costs already incurred.

You might not be able to see what’s happening, but taking an “out of sight, out of mind” approach can be costly.

To achieve optimal silage fermentation, a farmer has two priorities.

First priority: Stop oxidation

When freshly cut forage is piled, its temperature rises. Once this heating process starts, it can rapidly accelerate with the warm air rising and drawing in fresh air to fuel the “fire.”

As a result, the sugars in the crop can be burnt up quickly. First priority in silage-making is stopping oxidation of plant sugars by preventing fresh air from getting into the silo.

This is achieved by compacting and consolidating the crop. Once sufficiently compacted, cover the silo as quickly as possible to prevent fresh air from moving through the silo.

Second priority: Stop chemical and microbial activity

Even if the flow of fresh oxygen is stopped, freshly cut forage remains unstable due to other chemical reactions that continue.

Bacteria and molds that are naturally present can multiply rapidly and begin to decompose the crop. Undesirable microbial activity must be stopped as quickly as possible.

This is achieved by lowering the pH and creating an acidic environment where these microbes are deactivated.

Some of this happens automatically due to the natural bacteria present on the plant, but even by shutting off oxygen and achieving an initial drop in pH, a further reduction is necessary.

This reduction – in many cases to a pH level of below 4.0 – is needed to completely halt nutrient loss and undesirable microbial activity.

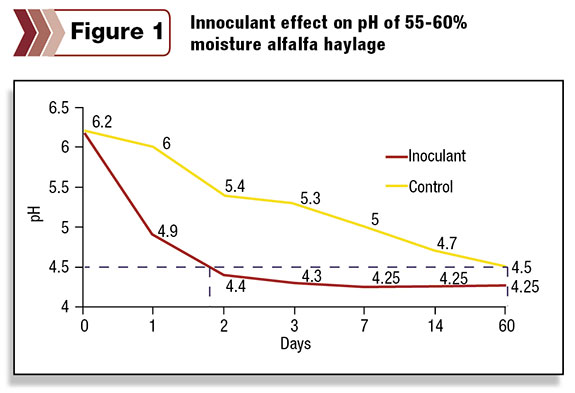

Effective silage inoculants will further lower pH and shut off microbial activity – completing the fermentation (Figure 1).

Effective silage inoculants will further lower pH and shut off microbial activity – completing the fermentation (Figure 1).

Will it pay off?

The cost of silage additives can range from 25 cents a treated ton to almost $2 per treated ton.

Of course, most sales representatives visiting your farm will tell you their product is the best.

It is important to do your homework and determine if the product you are purchasing actually works.

Spending 30 cents a ton on a product that does nothing to improve fermentation is a bigger waste of money than spending 30 cents too much on a product that does improve the value of your feed.

Evaluate additives based on value and not just cost. There are different features each company may offer, but the first characteristic of a good silage inoculant is how quickly it can lower pH and preserve the silage.

With new technologies that have come to market within the last few years, if you can’t see the difference and smell the difference, then the product is probably not worth your hard-earned money.

Application is everything

Another important variable to consider is application. Proper application is the biggest challenge facing farmers when it comes to silage additives.

There is not a product on the market that will work properly if the directions on the label are not followed correctly, and there is no such thing as bacteria with legs that will travel.

Inoculants should be applied at the harvester and calibration should be checked on a regular basis. Any other method of application will reduce effectiveness.

Silage inoculants are a sizable investment; consistent and uniform application must be a priority to protect this investment. Using too much can greatly increase costs, and using too little could be the same as using none at all.

In reality, making silage is not simple. It is easy for advisers (and editorial writers) to recommend how it should be done, but the truth is there are many variables – controllable and uncontrollable – that will affect the finished product.

It is important to focus on the fundamentals of fermentation. Silage inoculants are just one tool that, when used correctly, will prevent waste, preserve nutrients and make feed more palatable to your animals.

It only takes 24 hours for fermentation to have a considerable impact on 365 days of planning and hard work. So you decide: Pay now – or pay more later? FG

PHOTO

Bagged silage. Photo courtesy of FG staff.

Jim Mattox

Feedtech Solution Manager

DeLaval