Ensiling or fermenting fresh forage is an effective way to preserve nutrients, allowing us to feed animals year-round. However, the value and quality of silage is dependent on how well it was preserved. The primary goal of ensiling is to acidify the crop as quickly as possible, allowing for the preservation of nutrients. The fermentation of silage is affected by many variables like moisture level, type of forage, presence of oxygen, storage, bunk management, etc. When poor fermentation occurs, there is not only a reduction in nutrient quality, but it can result in silage containing toxins and metabolites that affect the cows’ health and performance. Silage inoculants are tools that can help control and ensure good fermentation under the right ensiling conditions.

How do inoculants work and what types of silage inoculants are there?

Silage inoculant kick-start the fermentation process, allowing for a faster reduction in pH, reduced nutrient breakdown and an increase in dry matter recovery. Ensiling involves lactic acid bacteria (LAB)fermenting sugars into lactic acid, which decreases the pH, limits nutrient breakdown and prevents the growth of undesirable bacteria, molds and yeasts.

There are two primary types of bacteria used within silage inoculants – homofermenters and heterofermenters – which have been well described in scientific reviews. In brief, homofermenters involve bacteria that produce one type of product, in this case converting sugars to lactic acid, which acidifies the silage. Silage inoculants can contain several genera of homofermenting bacteria which often serve different purposes. For example, certain strains of Lactobacillus plantarum can grow at a low pH, allowing this bacterium to continue acidifying the silage after the initial drop in pH. Heterofermenting bacteria produce several fermentation end products, including lactic acid, acetic acid and propionic acid. Acetic acid and/or propionic acid inhibits yeast and molds, which improves aerobic stability during feedout. Currently, Lactobacillus buchneri is the primary heterofermenting bacteria used in silage inoculants and is known for its acetic acid production.

Will my forage ferment without a silage inoculant?

Forage does contain an endogenous level of LAB that can allow for spontaneous fermentation under anaerobic conditions. However, the endogenous level of LAB is highly variable and can be affected by things like the type of forage, temperature, dry matter content, soil contamination, use of fertilizers, etc. The variability of the concentration of epiphytic lactic acid bacteria varies from 10 colony-forming units (CFU) per gram on alfalfa up to 1 × 107 CFU per gram on sorghum and maize. Lastly, the efficacy of the endogenous LAB is also variable, so we don’t know how efficient endogenous LAB strains are at converting sugars to lactic acid; we don’t know how effective they are in anaerobic environments or how well they utilize nutrients commonly found in various forages. By controlling the amount and the strains of LAB found within silage, we can ensure that under the right conditions, rapid acidification and stability can occur.

What else can my silage inoculants do for my silage?

Silage can also be a source of pathogenic microorganisms like Escherichia coli, Listeria monocytogenes, salmonella and clostridium. The presence of these bacteria in silage varies with their ubiquitous nature, the application of fertilizer or irrigation, or poor fermentation. These pathogens affect herd health and are a food safety concern.

Silage inoculants, like a probiotic, have the potential to reduce pathogenic bacteria that can contaminate forages. While LAB are growing and producing lactic acid, they are also producing antimicrobial compounds. Although low pH is the primary way to reduce the growth of these pathogens, LAB can inhibit them directly via bacteriocins and/or through competitive exclusion. However, the effectiveness of silage inoculants on controlling these pathogens depends on their growth within the silage, which requires good fermentation.

Some silage inoculants have also been reported to increase animal performance via mechanisms like reducing spoilage and increasing dry matter intake (DMI), improved nutrient utilization and improved ruminal microbial production. The reduction of pathogenic bacteria described above has also been a suggested mode of action in which silage inoculants can improve animal performance.

What do I need to look for when selecting a silage inoculant?

Here are a couple things to consider when selecting your silage inoculant:

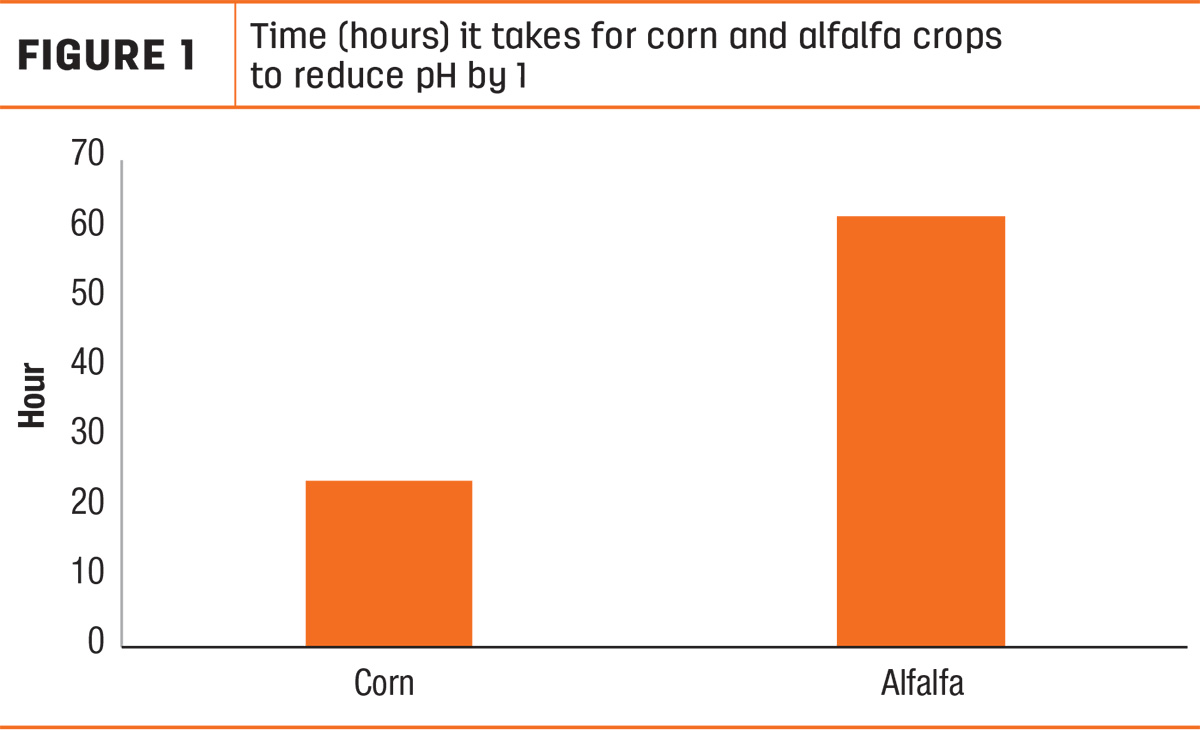

1. Type of crop – Hay and grass crop silages have a higher buffering capacity and low fermentable carbohydrates which can affect how quickly the crop acidifies. This is evident in Figure 1, when comparing the time it takes for alfalfa silage to reduce pH by 1 to corn silage (unpublished data).

Using homofermenting bacteria on these types of crops can offer a lot of benefits in the ensiling process. Enzymes can also be added to these types of crops to ensure there are enough nutrients for LAB to initiate fermentation.

2. Dry matter content – Drier silage tends to be harder to pack, which will affect how well oxygen can be eliminated, leading to a slower decline in pH. There is also evidence to suggest that high-dry-matter corn silages treated with a strain of L. buchneri had better aerobic stability when compared to corn silage with low dry matter. So using both a heterofermenting and homofermenting bacteria when dry matter conditions are not optimal is often advised.

3. Feedbunk management – Silage stability is highly dependent on the exclusion of oxygen. Once we begin to feed silage, the face of the bunk goes from an anaerobic to an aerobic environment and silage begins to spoil. Determining how quickly the silage is being used and how well the bunk face can be managed may determine the need for heterofermenting bacteria to be included in your silage inoculant. Heterofermenting can improve aerobic stability and help control spoilage at the exposed bunk face.

4. Silage inoculant viability and handling – In order to be effective, the bacteria in silage inoculants must be alive. Bacterial shelf life is dependent on the strains of the bacteria, how the bacteria is dried and how the silage inoculant is stored. The bacteria within silage inoculants must also be viable during inoculant application and able to grow during the ensiling process. Viability of bacteria can also be affected by the application conditions like tank temperature, water quality, time spent within the tank and the strains of bacteria selected for ensiling. Working with your inoculant provider to verify manufacturing guarantees and quantify silage inoculant viability at time of application can help ensure silage inoculants can be effective as possible.

5. Pathogenic load – The effect of silage inoculants may go beyond silage. Controlling pathogenic bacteria within the bunk may be a way in which silage inoculants can not only improve silage quality but help improve animal health.

References omitted but are available upon request. Click here to email an editor.