By May 2013, they were ready to start building. A new composted bedded pack barn and two robotic milking units replaced their old barn. The Byces started milking again at Heathervale Farms in Beachburg, Ontario, in February of this year.

The new barn can hold 130 cows. Currently, they have 77 milking cows on one end of the barn and bred heifers and dry cows on the other end.

Previously, bred heifers were kept in a building just off the hay shed and dry cows in a wing off of the old barn. “Now, they can be close by when they are ready to calve,” Harry says.

In addition, the new construction project wasn’t confined to the same location as the old bank barn. “We were able to take advantage of a new location for better ventilation.

The 25 cows that did survive the fire (14 milking and 11 dry cows) came back to a huge difference in terms of ventilation, lighting and cow comfort,” Celeste says.

What did the disaster take away that you will never be able to replace?

HARRY: The genetics of the cattle and my memories of the old barn. I’ve lived here all my life, and that barn was always a part of me.

Name at least three improvements you have been able to make by having to rebuild.

HARRY:

1. It has been a lifestyle change. With the robots, we’re not as regimented with a milking schedule to follow.

2. I’m feeding faster each day with drive-through feeding.

3. More efficient dry cow and calving facilities.

Name one thing the disaster took away, but now that it has been replaced or restored, you’re not sorry it was lost or damaged in the first place.

HARRY: The old tiestall barn had higher labour demands. We can now do more ourselves without spending our time physically milking our cows.

CELESTE: Harry can now attend our children’s soccer and baseball games. We no longer have to start hurrying at the beginning of the day just to finish early in the evening.

There is still a lot to do each day, but more can be monitored from the computer in the house. Cow activity (heat detection) and milk quality can be seen on the computer.

At first it was way too much information, but compared to visually observing each cow in the tiestall, we now only have to pay close attention to the cows that show up on the computer-generated list.

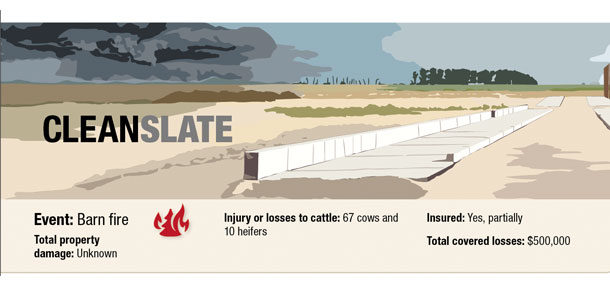

What did you learn about insurance through working with your insurance company to recover your losses?

HARRY: We learned we didn’t have enough. The barn and cows were covered losses, but the three silos and four grain bins were not. We also found we did not have enough income interruption insurance.

As the farm grew, we didn’t adjust that number. All in all, the company was good to work with, but we should have reviewed our policy because there were things we thought were covered but weren’t.

How would you insure yourself differently now having gone through this experience?

CELESTE: We’re covered better now because the new barn is worth more. We’re going to be more diligent in reviewing our coverage and the specific terms.

Is there anything you have done already or will do in the future to protect against this happening to you again?

CELESTE: The inspectors were unable to discern what caused the fire. The new building codes were completely different from what we had before. There isn’t any knob-and-wire electrical or any unprotected wires. A firebreak was placed in the rafters.

HARRY: The old barn was built in the 1800s and full of dry timbers. The new ceiling is all galvanized steel. There is no longer a haymow filled with straw, hay and dust that can fuel a fire.

At the time of the fire, we were in the process of updating the old wiring and lights.

CELESTE: We had worked backwards from the feed room and hadn’t quite got to everything on the far end where the fire began.

Any advice you might have for producers who may be at risk for a similar situation?

HARRY: Make an effort to upgrade old electrical and make sure you have enough insurance.

CELESTE: Make sure it is the right insurance for you with the right value and replacement costs. Also, see to it your income disruption insurance is geared to your situation.

What outside support did you receive that helped you through this difficult time?

HARRY: My first concern was what to do with the cows that survived. A neighbour, whose family went through a fire several years ago, made the phone calls and lined up trailers to take our cows to four different farms, which kept them for a year and a half along with anything else that calved during that time.

We were fortunate to have 50 milking cows come back to our farm. A couple of guys baled our hay and harvested our crops. People came forward with donations, and we received support from our community.

CELESTE: We continued to get a lot of support through the start-up of the new facility. The contractor came back to check on how everything was working, and his crew was there to help us push cows through the robots the first few days.

The robot representative and electrician were there to keep things going, especially through three unexpected power outages. We held an open house in May and had a great showing of support from our community. PD