The most frustrating curveball is pitched from Mother Nature in the form of the weather. Oftentimes, the newspaper, the television, the radio and now the app forecast weather that changes.

Forage quality is one of the most important allies of a successful dairy. The weather can be the biggest adversary on the dairy. Sometimes, these two come together to make a forage the nutritionist and the herd simply love – the kind of forage we can bring to our face and just take in the aroma.

In 2020, much of the country experienced above-average growing-degree days, and most areas had ample rain. There were some areas that were short of rain, and then of course there was the derecho that visited Iowa. In the northeastern U.S., we saw 100-year highs in heat that made for some great corn weather – the kind of weather our friends in the Corn Belt often see. But Mother Nature threw a major-league curveball for many areas of the Northeast in mid-September. Four nights of temperatures below 28ºF made the bottom drop out of a spectacular corn season.

An excellent example of this was from an on-farm plot in Vermont when looking at the application of fungicides and foliar feeding at tasseling. The initial goal of the trial was to compare the impact of fungicide and foliar applications on corn silage on continuous corn ground that has shown an annual increase in mycotoxins. Fusarium molds such as Fusarium graminearum, if given the correct temperature and water activity around tasseling, have shown a high risk for systematic infection of the silk channels in the plant. Much work has been done with fungicides at this stage to reduce vomitoxin levels. Work from Ontario has shown vomitoxin reduction when applied at the proper time with the proper class of fungicide.

Treatments were applied to strips within a field at silking at the end of July. The crop looked great and weather had been favorable, with consistent rains and ample growing-degree days. Each treatment was tested at the time of treatment for mycotoxins using liquid chromatography and double mass spectrometry (LC/MS/MS). Levels of vomitoxin were very low, with four of the five treatment strips with zero DON (deoxynivalenol) and only one treatment showing any detectable level (0.356 ppm).

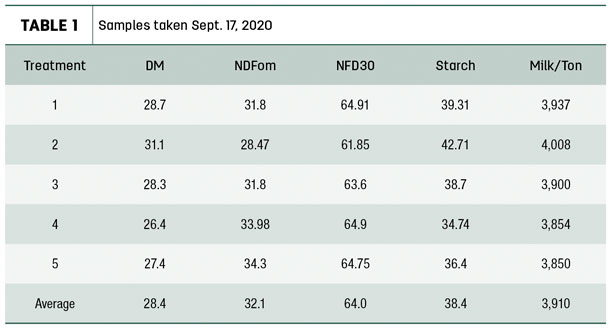

There were 1.45 inches of rain in early August, but Mother Nature decided to greatly reduce the precipitation over the next six weeks, which is a critical time for starch deposition and ear growth. On Sept. 17, samples were again taken from each treatment for quality and mycotoxins. Vomitoxin levels averaged 0.257 ppm across the plot. The levels through the high-risk tasseling period showed promising results. Dry matter (DM), quality and starch parameters were measured as well (Table 1).

At this point, the corn crop looked great. Whole-plant DM average was 28% and with an estimate of 0.5% drydown per day, coupled with an average accumulation of 10 to 12 growing-degree days per day, the estimate of two to three weeks harvest was upon us.

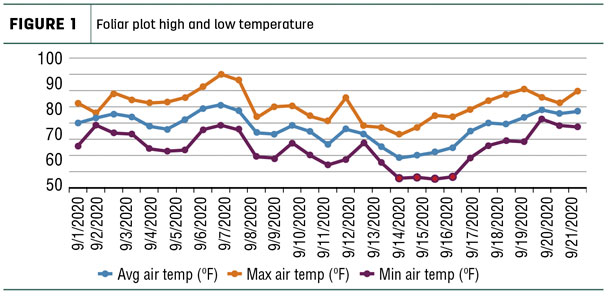

The next night, Sept. 18, an early season cold front came through, and with it came four nights under 25ºF for a few hours each night (Figure 1). A killing frost is thought of as a few minutes below 28ºF.

With a killing frost on immature corn, we will often see cell rupture, epiphytic mold growth, a halt in starch deposition and finally a rapid whole-plant drydown. With corn silage harvest in full swing and plans for the plot to come off at the end of September, we prepared to harvest the plot on Sept. 29. After the frigid curveball of low temperatures, Mother Nature decided to turn up the heat, humidity and add in some windy days. This was a perfect recipe for rapid whole-plant drydown, to the tune of 16% in 12 days. As many others have experienced, the post-frost drydown seemed like a runaway freight train; whole-plant DM at harvest ballooned to a plot average of 45% DM.

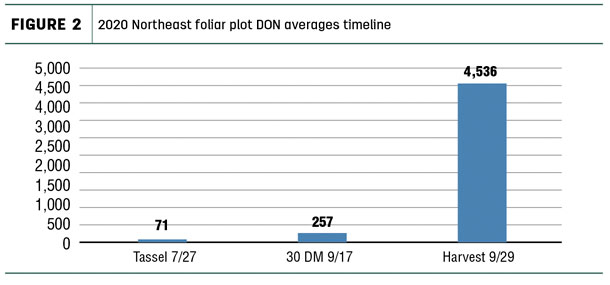

The plant crinkled to the touch and had that familiar musty smell and gray-brown appearance. Quality and mycotoxin tests were taken, and a crop that had so much glorious potential showed the effects of Mother Nature’s nastiest curveball. Trial-wide, vomitoxin levels increased 17 times in a mere 12 days to an average across the plot of 4.6 ppm (Figure 2).

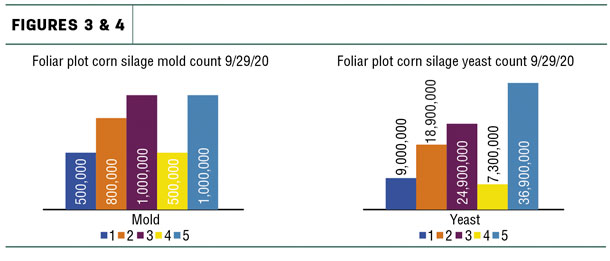

Mold and yeast counts were taken at harvest (Figures 3 and 4) and were reflective of a traumatic event in the plants’ demise.

Quality numbers were not affected nearly as much as the forage hygiene and high DM that can impact the ability to correctly pack the bunk.

What can we learn?

Sometimes the most informative trial results are a byproduct of unintended circumstances. All farms have experienced a traumatic weather event, and we know bad things can happen to good forage. Many of us have dealt with the aftereffects of a traumatic event with a forage, but the importance of what we learn from it and how we can reduce the risk is invaluable.

Here are a few lessons learned from the trial, in case your farm runs into a frosty curveball:

- After a killing frost, monitor whole-plant dry matter (DM) every couple of days to ensure harvesting at a DM of 33% to 38%.

- If the whole-plant DM is above 38%, make sure length of chop is reduced and kernel processing is on point.

- Harvest promptly with an adequate bunker density while utilizing a proven inoculant.

- Sample the forage at harvest to screen for potential hygiene and mycotoxin issues in order to plan ahead for feedout.

With practice, a major-league baseball player can learn to hit a curveball, and our dairies can learn to adjust to what Mother Nature throws at us. Batter up! ![]()

John Winchell is a territory sales representative for Alltech. Email John Winchell.