Poor air quality, holes in the ozone layer and “the greenhouse effect” have been increasing environmental concerns for some time. Recently, this has led to greater interest in the production of volatile organic compounds (VOCs) from dairy-related sources, especially silage. In this article, we will define VOCs and how good management may reduce the impact.

VOCs defined

VOCs comprise thousands of individual reactive gases that include groups of compounds such as ketones, alcohols, organic acids, amines, etc. VOCs can combine with nitrogen oxides in the presence of sunlight and form ground-level ozone, which can then form smog – a toxic gas that can result in allergies, nausea, respiratory diseases, immune depression and irritation.

Since there is an abundance of nitrous oxide formed from the combination of oxygen and nitrogen due to the use of fertilizers, microbial activity and fuel combustion, controlling the formation and emission of VOCs has become the limiting factor for ozone formation by default.

The highest ozone levels in the U.S. have been recorded in California’s San Joaquin Valley. Moreover, particular attention has been given to California as the country’s largest dairy state and, recently, due to studies identifying animal feed VOC emissions as the second principal contributor to ozone formation in the San Joaquin Valley.

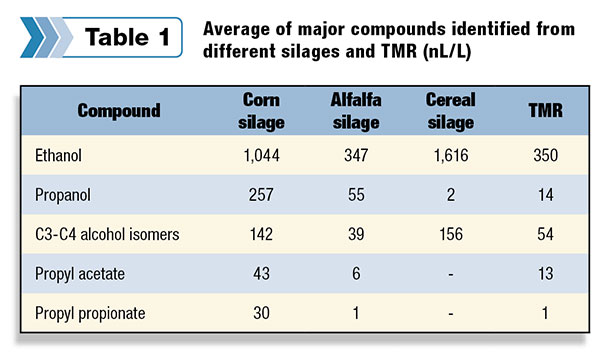

VOC emissions from animal feed sources are significantly higher than those from animal waste emissions. The majority of the compounds identified emanating from open-faced silages piles and bunkers are alcohols, with ethanol – a common product of yeast metabolism – being dominant (Table 1).

Yeasts are naturally found in forages and are considered unwelcome guests in the silage process. Different types of yeasts are involved in both of the active ensiling and aerobic spoilage processes.

Fermentative yeasts compete with lactic acid bacteria for sugars during the aerobic phase early in the ensiling process, producing substantial amounts of CO2 and ethanol, plus some volatile acids and other alcohols.

On the other hand, lactate-assimilating yeasts can quickly rise to become predominant in the presence of air, during feedout, and are responsible for the great majority of heating events and initiating aerobic spoilage. Ethanol is also the main product of their metabolism.

The emission of ethanol from silages is impacted by both climate and management practices. Published research has shown that the emission rate of ethanol from corn silage increased with temperature, silage porosity, exposed surface area and air velocity at the silage surface.

Silage management best practices

Fortunately, management practices to decrease VOC emissions from silages are consistent with practices intended to minimize dry matter (DM) and nutrient losses, and enhance feed quality, stability and overall preservation.

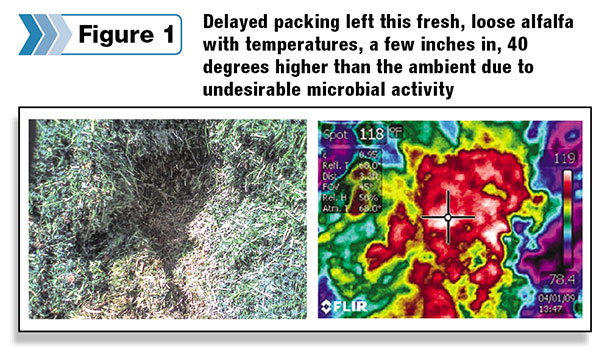

Removal of air from the forage mass stimulates the ensiling process and inhibits undesirable micro-organisms. Therefore, filling the silo quickly and packing tightly are vital regardless of the silo structure (Figure 1).

Silage density is directly related to depth of silage, packing tractor weight, packing time and DM content. Excel spreadsheets are available at the University of Wisconsin Extension website to help optimize packing conditions, silo size and capacity.

To reach a desired packing density and achieve the best possible fermentation, some management parameters need to be controlled. For instance, the target DM range of the crop to be stored in bunks and piles should be between 32 and 38 percent for corn silage and 35 and 45 percent for haylage.

Lower DM values stimulate clostridial fermentation and increase effluent losses. High DM forage will likely be more porous and allow greater ingress of air into the silage, increasing the probability of aerobic instability. Theoretical length of cut also plays a role in this process. And it has to be set according to the crop type, use of kernel processing (in the case of corn) and amount of the forage in the diet.

Theoretical length of cut needs to be set to meet your specific conditions and needs; for example, a drier crop is harder to pack and may benefit from short theoretical length of cut. Air in the silage mass can also be minimized by even distribution of forage in the silo during filling, facilitating packing.

Last but not least, the silo should be immediately sealed after filling, most commonly with plastic and tires. It has been estimated that the value of spoiled silage is at least four times the cost of buying plastic and tires, including the cost of labor to install and remove them.

During fermentation under anaerobic conditions, the ensiling process is dictated by adequate moisture level and amount of sugars available for the dominant population of micro-organisms to utilize. To make this process effective, the use of inoculants containing homolactic strains of bacteria is recommended, since these microbes efficiently convert one molecule of glucose to two molecules of lactic acid.

Lactic acid is about 10 times stronger than other acids (acetic, propionic), resulting in faster acidification and subsequent inhibition of ethanol-producing micro-organisms.

Chemical additives are another option to reduce fermentation losses and improve silage quality and stability, but be aware of potential handling issues.

Lactobacillus buchneri belongs to a different class of microbial inoculants because it is an “enhancer of aerobic stability.” This bacterium produces moderate amounts of acetic acid during the storage period and inhibits growth of the yeasts responsible for heating and spoilage during feedout. The result is silage that is “fresh” longer.

VOCs and silage research

There is a lack of data on the effects of forage additives on VOCs, but some research was presented during the Joint Annual Meeting of ADSA and ASAS in July 2014.

Dr. Limin Kung Jr. from the University of Delaware and collaborators led a couple of studies evaluating these additives and their potential effects on VOC profiles in the finished silage.

In one experiment, a potassium sorbate-based product was efficient at reducing the production of several important VOCs and improving the aerobic stability of corn silage. A homofermentative inoculant was also tested, but there was no difference compared to untreated silage.

In another study, also with corn silage, the use of Lactobacillus buchneri 40788 markedly changed the silage VOC profile, including reducing ethanol content, as well as a decrease in the population of yeasts.

Ethanol has been a common parameter analyzed in silage experiments. However, to date, little attention has been given to the other alcohols, ester, organic acids, aldehydes and ketones that compose VOCs.

Management practices during feedout also are important to reduce VOC emissions. Keeping a clean, smooth silo face decreases the oxygen penetration behind the feedout face. The amount of loose silage on the silo floor should be minimized, as should the time of exposure to air.

High face-removal rates reduce the time that spoilage microbes may have to actively cause feed losses; thus, a silo should be designed based on the daily silage needs of the herd, resulting in a removal rate of at least 6 inches per day.

Most of these recommended management practices were included in Rule 4570, implemented by the San Joaquin Valley Air Pollution Control District to reduce the potential of smog formation from silage VOCs.

In other U.S. states, the use of the management practices listed in this article would not only help ensure the production of good-quality silage with maximum retention of DM and nutrients but also help reduce the growth of spoilage microbes, especially yeasts, and the concomitant levels of adverse products such as VOCs. PD

Bob Charley has a Ph.D. in applied microbiology from the University of Strathclyde in Glasgow, Scotland. Renato Schmidt has a Ph.D. in animal nutrition from University of Delaware and is employed by Lallemand Animal Nutrition as a forage products specialist.

Bob Charley

Forage Products Manager

Lallemand Animal Nutrition