We are also continually improving in areas of land conservation and stewardship. For many years, manure was viewed as something we had to “get rid of” and has been a “waste product” (pun intended).

Obviously, manure has tremendous benefits, both economically and nutritionally, for growing various crops and can be a strong facet of conservation with regenerative agriculture, especially if commercial fertilizers can be reduced in the operation. Currently, we see commercial fertilizer increasing in price or even becoming difficult to acquire in some areas of the country.

Here are some points of manure management to keep in mind to maximize its value of application:

1. Soils testing – It is important to first test your soils where manure will be applied to understand what nutrient deficiency or surplus is present. From there, you will be able to create a good application plan that will correspond with crop nutrient management plans.

2. Manure testing – This step is also critical to understand how much manure can be applied based on a given soils test. It will also be important to know what crop will be grown after manure application and to know the nutrient requirements of that crop based on targeted yield goals. It is important to note, not all manure is created equal. Compost versus fresh, poultry versus beef, dry versus liquid – each will have its own unique nutritive values based on the animal, feed quality and type from year to year. Ensure you know what levels of nitrogen, phosphorus and potassium are in the manure to be applied for best results and management.

3. Application and placement – Based on the type of product you are applying (liquid or solid), there are varying methods of application, but more important is what we do with the manure after application. If we go through all the painstaking work to analyze the soil and manure, while ensuring proper application rates, it would be a shame to lose 30% to 50% of the nutrient value before the first seed is planted.

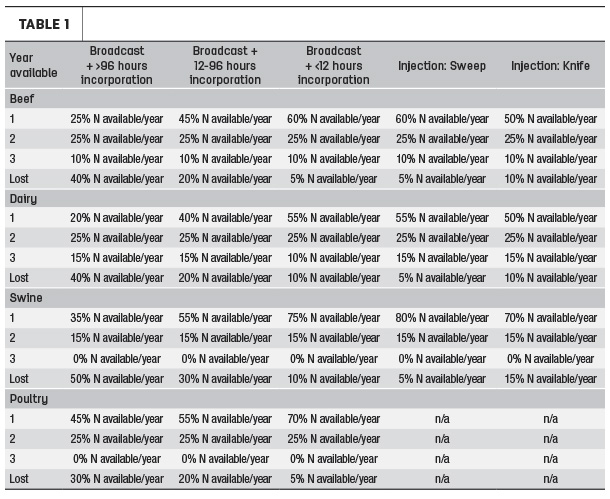

This is where proper and timely incorporation of manure comes into play. Based on studies from the University of Minnesota (Calculating manure application rates; Table 1), if manure is allowed to stay on the surface longer than 96 hours, much of the valuable nitrogen can be lost to volatilization.

The big benefit to incorporating this manure in less than 12 hours is seen immediately in the availability of nitrogen in the first year of production.

This same study shows that while shallow incorporation of manure is better than leaving it on the surface, injection or deeper incorporation into the soil has a longer-lasting benefit of nutrient availability in successive years of production. This can be an added benefit as crops develop deeper root profiles and generally require more available nutrients later in the growing season. Moisture is also generally more available deeper in the soil profile, which is required for good nutrient absorption by high-yielding crops.

Manure application also has a strong biological benefit for soils. Soils are made up of many components, but none may be more important than the micro-organisms, bacteria and fungi that interact with the plants to aid in moisture and nutrient uptake. The addition of manure to soils ensures that this biological activity is maintained in the soil environment, providing much-needed nutrients for healthy soils and, ultimately, improved crop production.

Equipment

Several tillage machines can be used to properly incorporate manure into your fields based on your operation type and conditions. Disc harrows have largely been used due to their reliable ability to consistently mix manure and soil into the top 3 to 6 inches of the soil profile. Vertical tillage and high-speed discs are also popular choices in the current market for manure incorporation and offer increased flexibility based on adjustable gang angles, finishing harrow attachments and acre-eating operational speed.

For deeper manure incorporation, coulter chisels or combination primary tillage machines with operational depths of 8 to 16 inches can serve a dual purpose. These machines can effectively move manure deeper in the soil profile which will provide much-needed nutrition to plants later in the growing season and will also remove compaction generally created by heavy loads of manure-handling equipment. The dual benefit provided by conserving valuable nutrients and creating an ideal root environment with adequate air and water pore space make these machines extremely valuable for proper manure and soil management in a high-yield crop environment.

Manure application can be a positive tool for saving costs, as well as increasing yields, and with timely incorporation through tillage can greatly influence soil health and sustainability for the future. ![]()

Curt Davis is the director of marketing and product management at Kuhn Krause Inc.