As a mom of three boys, one of my biggest pet peeves is a sink full of dirty dishes that no one else seems to notice. I have even threatened my boys that if they don’t put their dishes in the dishwasher (which is right next to the sink), dinner will be served on dirty dishes. Luckily, I’ve never had to follow through on that threat because, let’s be honest, that would be gross. One might ask: What does this have to do with feeding cows? I’ve come to the conclusion that feeding cows is eerily similar to feeding boys. They like to eat a lot, they don’t do a very good job cleaning up after themselves, and I seem to be the only one concerned about them eating a balanced healthy diet that’s fresh and nutritious.

When it comes to feeding cows, we spend a lot of time focusing on the nutritional aspects of the ration. What’s the digestibility, crude protein (CP), starch content? Do we hit our fiber goals and energy goals? We work to balance for amino acids, focus on dry matter intake (DMI) and try to minimize sorting. We spend a lot of time ensuring the ration meets all the nutrient requirements of the animal depending on the stage. However, I would argue that we need to be aware of any anti-nutritional factors which may be present in the diet, as this can quickly negate our hard work.

Anti-nutritional factors are substances that, when present in animal feed or water, either directly or indirectly through their metabolic products, reduce the availability of one or more nutrients. The anti-nutritional factors that draw the most intense scrutiny would be pathogenic microorganisms and toxins. The most common pathogenic microorganisms found in poorly fermented silages are Escherichia coli, specifically E. coli 0157:H7, Listeria monocytogenes, Bacillus spp., salmonella and Clostridium spp. If these pathogenic microorganisms make their way into the rations we worked so hard to perfectly balance, they aren't going to provide the nutrients they should and, worse, may lead to health challenges or lost production. Being aware of contamination risks and having strategies in place to reduce these risks are the first steps to ensuring the rations stay high in quality. While evaluating forage or ration hygiene once in the bunker or feedbunk can tell us if any anti-nutritional factors are present, it’ll be too late to prevent but allows us to develop a mitigation strategy.

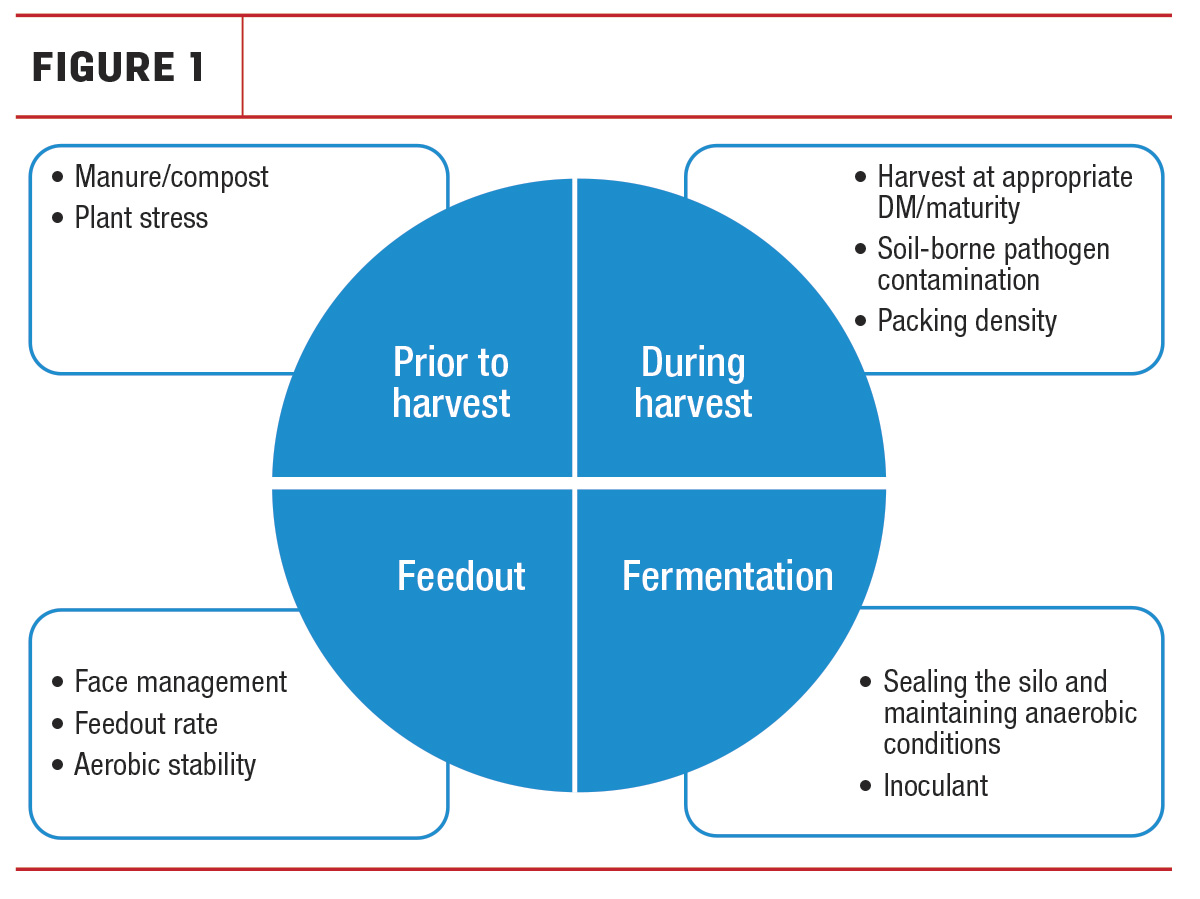

Forages can be contaminated with pathogens before, during and/or after ensiling (Figure 1).

Forages can be contaminated with pathogens before, during and/or after ensiling.

Forages can be contaminated with pathogens before, during and/or after ensiling.

These pathogens can be detrimental to animal health, productivity and lead to negative impacts on overall profitability. Therefore, it is critical that adequate control measures are used at each of these stages to prevent contamination.

The first step to reducing the risk of pathogenic microorganisms begins well before harvest. Manure slurry, compost and irrigation water can provide nutrients for plants and soil; however, they also carry the risk of introducing pathogens, particularly E. coli and clostridium. Ensuring manure is incorporated into the soil prior to planting and allowing a minimum of 28 days from manure application to harvest are essential steps during this phase.

During harvest, the greatest risk factor is adding more clostridium to the forage from soil contamination. Although Clostridium spp. are normal flora of ruminant digestive tracts, dietary stress, injury, management changes and parasitism can make them produce potent toxins that cause sudden bouts of abdominal pain, diarrhea, ulceration and even death. Clostridium are ubiquitous in soil and have an affinity for moisture; therefore two best management practices during harvest include reducing the risk of soil contamination by managing mowing height and harvesting at the appropriate moisture content.

Best management practices before and during harvest help set the groundwork for optimal fermentation, leading to feed that is stable after ensiling at feedout. To determine which bacterial silage inoculant is the best solution, it’s important to know what stressors the plant may have encountered and what risk factors prior to ensiling couldn’t be corrected with improved farming management. This will help ensure an optimal fermentation once the forage is harvested. Before fermentation can begin, oxygen must be removed through packing. Following “the rule of 800” (optimal packing tractor weight = 800 pounds of packing weight for every ton of forage delivered per hour), filling the pit in thin layers (4 to 6 inches) at a time and packing the pile in a progressive wedge configuration will facilitate achievement of higher-density bunkers and piles. Once packing is completed, a top-layer preservative can be applied for increased nutrient preservation, and the pile is ready to be sealed with oxygen-barrier plastic. Cover quickly, efficiently, thoroughly and safely.

Now that we have done everything to ensure an optimal fermentation, we don’t want to risk spoilage at feedout. Yeasts, molds, listeria and enterobacteria that survive anaerobic fermentation grow rapidly when oxygen is introduced, and pH is elevated during feedout, leading to aerobic spoilage. Therefore, management practices that ensure the aerobic stability of silages and prevent increases in pH at feedout are critical. Face width, defacing management and feedout rate are all critical factors to minimize the amount of silage surface area that is exposed to oxygen. Feedout rates of 2 to 4 inches per day from tower silos, 4 to 6 inches per day from bunker silos and 12 inches or more per day from bag silos are recommended. In addition to management practices, inoculants containing specific strains of Lactobacillus buchneri enhance the aerobic stability of silages.

Prior to feeding a new forage, or if you have concerns about anti-nutrients being present in your feed, you can submit ration or forage samples for analysis. Ration, forage and even water trough samples provide you with a perspective of what the cows may be consuming. Sampling individual forages can also help pinpoint the challenges found in ration samples that come back high in anti-nutrients. If you are submitting a ration sample, it is important to remember that if you are using a live yeast product, you will need to back calculate the amount you added to the ration.

What are some practical effective mitigation strategies if anti-nutrients are present? Quickly identifying the contaminated feeds/forages, feeding less of the contaminated feed/forages in the lactating ration and prioritizing high-quality feed for lactating animals. The final piece of the puzzle is maintaining a healthy environment within the digestive tract of high-producing dairy cows throughout the entire life cycle, not just when a challenge is present. This is most effectively accomplished by feeding a science-based, research-proven probiotic that provides essential microbial support to the natural digestive, immunological and barrier function properties of the rumen and intestinal epithelium. It is important to note that if the feed is highly contaminated or resembles compost more than silage, it may need to be disposed of because even though feed is expensive, sick and dead cows are more costly.

From the field to harvest, ensiling and feedout, bacteria, mold and yeast have the potential to contribute significant anti-nutritional components to forages. Dry matter shrink, digestible nutrient loss and negative effects on the digestive system and the overall health of your herd are three major consequences. Utilizing best management strategies throughout the whole cycle helps reduce the risk of having to deal with contaminated forages and sick cows.