To read this article in French, click here.

Automated milking systems have gained popularity in recent years for a variety of reasons, whether it is reducing labour, gaining a more-flexible schedule or desiring herd management data. When most dairy farmers add robotic milking systems to their operations, they also build updated freestall barns at the same time.

While these construction projects offer the newest advancements in barn and robotic facilities, the price tags can be hefty. To reduce costs, some dairy farmers have opted to renovate existing tiestall barns to include automated milking systems. But this is not simply unlocking cows and expecting them to start milking in a robot. With careful planning and the consideration of these seven factors, you can successfully automate your existing tiestall facility.

1. Evaluate your current barn

Is the facility structurally sound? It may be adequate for today’s herd, but renovations could stress beams that are just holding on. Also, herd size and compatibility with a robotic milking system is another strong consideration. Generally, most robotic herds are between 55-65 cows per robot, depending on several factors. With a renovated tiestall, will the new facility properly house the number of cows and robots desired, or will an addition be necessary to accommodate the herd, robot room(s) and support equipment?

2. Account for proper ventilation

Generally, tiestall facilities have low ceiling heights with few fans. When reconstructing the structure, one option is to raise the ceiling and install better ventilation (left photo). Raising the ceiling also helps make room for larger equipment used for feeding, bedding or scraping.

3. Go from tiestalls to freestalls

This switch has many benefits. By having properly sized stalls, cow comfort easily increases while also giving the producer more options for bedding material (right photo). Traditional tiestall cows will have to be trained to use freestalls, as alley laying may happen for a while as they acclimate.

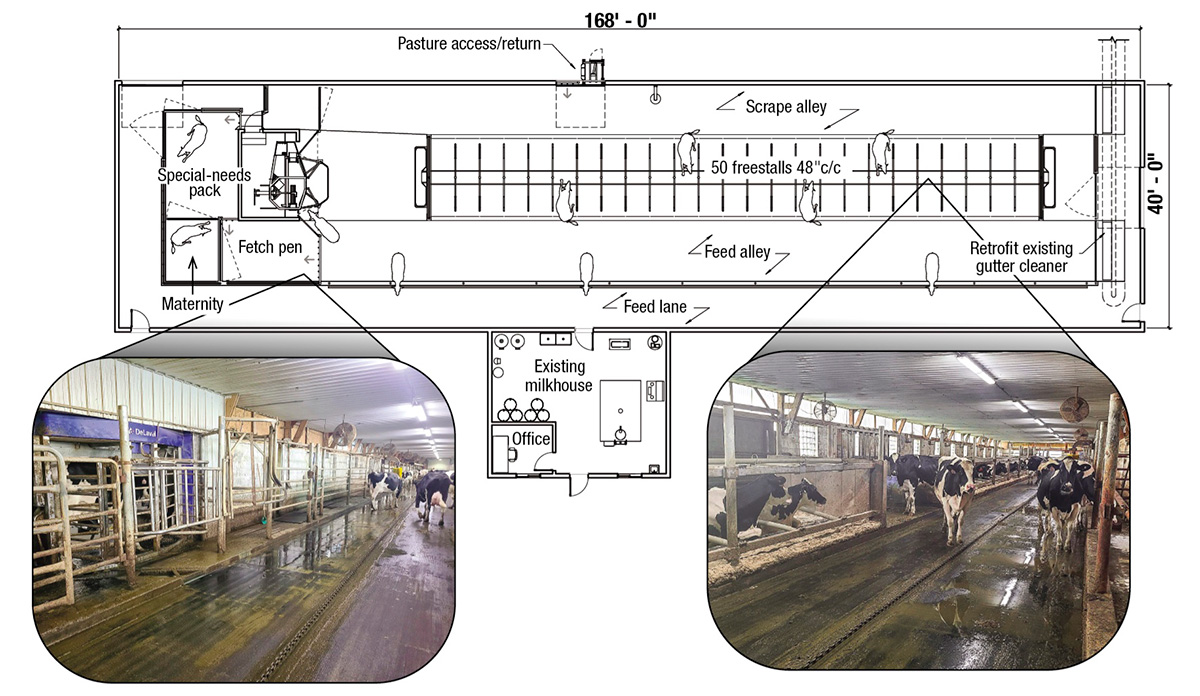

The floor plans of a guided-flow robotic milking system barn retrofitted to a tiestall barn. Photos and illustration courtesy of DeLaval.

The floor plans of a guided-flow robotic milking system barn retrofitted to a tiestall barn. Photos and illustration courtesy of DeLaval.

4. Update the manure system

Consider what would fit best with your current manure handling. Installing alley scrapers, scraping with a skid steer and tire attachment, or adding a manure robot are viable options and depend on how the producer wants to structure the system and schedule.

5. Motivate the cow

In a tiestall facility, feed, water and the milking machine come to the cow. The cow's motivation to move is extremely low. With a robotic conversion of a tiestall barn, cows will need to be motivated to utilize the robot. The pressure of milk in the udder has not shown to be as motivating as we would like to believe. By separating stalls from either feed and/or water, cows will learn they must go throughout the barn to accomplish their needs.

6. Choose free-flow or guided-flow

Both setups work great in tiestall conversions. In free-flow, the driving factor for a cow is the energy it gets from pellets available in the robot. A cow will enter the robot several times a day seeking pellets, and it will be rewarded with them when it has enough expected yield to merit a milking. In guided-flow, a cow’s motivation to eat, drink, milk or lie down will motivate it to move throughout the barn via a selection gate. Comparing and contrasting these different setups while aligning them with your individual herd goals will help you decide which barn layout will work best for your facility and management style.

7. Make a temporary plan for milking

As renovations get underway, what will you do with the herd? If doing a major overhaul, the barn will be likely unusable. One solution is to rent an empty barn for a few months to house the herd while the retrofit is happening. Another option is to shorten the milk pipe to create a flat barn parlour with the cows living outside and switching in a few stalls at the end of the barn.

During any planning phase for robotics, it is important to gather opinions, research and experience from a variety of places. Working with your trusted dairy advisers and equipment dealership, and touring successful robotic operations, will help guide your plans.

About this tiestall barn-to-robotic-milking-facility conversion

This existing 40-by-168 two-row, tail-to-tail tiestall barn has been converted to a two-row freestall facility. It features a 56-cow free-traffic design with sorting for special-needs cows and seasonal pasture access. This barn incorporated its existing manure gutter cleaner and ventilation system as well as the existing feed cart to deliver feed.