A Wisconsin dairy’s new barn captures the advantages of a traditional cross vent but with an innovative design: adjustable curtain baffles to control air flow.

Dan Smits and his brother Steve, who own Double S Dairy near Markesan, Wisconsin, broke ground for a new barn late last year in order to bring heifers home from their off-site location earlier. “One of our goals was to get heifers in freestalls sooner than one month prefresh,” Smits says.

Manure storage was the limiting factor at the heifer farm, so the solution was to make room for these animals at the dairy’s main site, which had additional manure capacity already in place.

Putting up a third barn to join the existing four-row and six-row naturally ventilated barns would provide space for 300 heifers in addition to the 1,420-cow herd.

Weighing out the options

Before dirt was moved, there were many meetings, tours, drawings and discussions over what type of barn to build. The brothers looped their key herdsmen into these conversations, including long-time employee Butch Guenther, who has worked on the dairy for almost 20 years.

Together, they outlined their priorities: good ventilation, good lighting and enough room for cows to eat and rest comfortably.

“We almost built a six-row, tunnel-ventilated barn,” Smits recalls. Certain aspects of the six-row style appealed to him, including specific sizes for each group of cows, but Ken Nordlund’s recommendations echoed in his head. “I read an article on how prefresh cows absolutely need 30 inches of bunk space,” he says.

“We were scared to build something new with only 16 to 18 inches. We didn’t want to wish we could change our minds later.”

Guenther concurred, adding, “The more time I spent in the six-row barn, the less I liked it. There is not enough space and too many feet in a small area.”

They agreed that a four-row configuration would provide better access to feed and ample room to rest. Further, the layout of the cross vent would take up a smaller footprint than the longer, larger six-row tunnel design.

The group also weighed out the pros and cons of lighting. While they liked the airflow and quality in the cross vents, they admired the open feeling and natural lighting in the tunnel-ventilated barns they toured. “I didn’t want to work in a dungeon,” Guenther says. “We didn’t want a dark environment.”

To address this concern, the team considered smoke panels, which would allow more sunlight into the building. However, they feared that it could get too warm in the summer, so they settled on putting smoke panels in only the south end of the barn. The north end is sealed and insulated.

Trying something different

While the Double S team knew they liked what a cross vent style could offer, they were not sold on baffles.

“We weren’t sure if we wanted baffles. We wanted good air flow and fresh air, but we didn’t want it to feel drafty,” Guenther explains. “There are certain times of the year (during cold weather) when you don’t want air blowing right on the cows.”

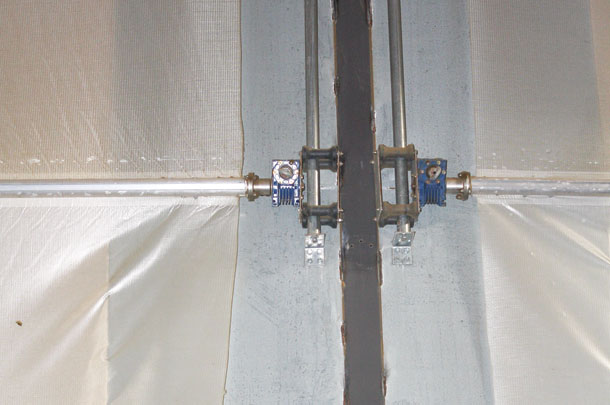

They recalled a barn they had toured which was planning to put in an adjustable curtain as a baffle for this very reason. After going back and forth on the idea, they pulled the trigger.

“We did it, and all winter we had a wide, open barn, and when it started getting warmer, we rolled the curtains down,” Guenther says. The baffles, adjusted with a hand crank, have been down now since early May. He expects to keep them down for about four or five months. On the hottest days so far this year, a constant breeze cools the barn at 7 to 9 miles per hour.

The adjustable baffles also keep the barn from feeling like a “dungeon.”

“It’s so open; it’s not dark and dreary,” Smits says. “Light-wise and air-wise, it’s a great place to be, whether it’s cold or warm out.”

Comfort and convenience

Smits and Guenther agree that their new barn provides a comfortable place for both cows and people.

Four temperature probes are located throughout the barn, which signal the 58 60-inch variable-speed fans to automatically ramp power up or down incrementally. Once the temperature inside the barn reaches 60 to 65ºF, all fans are running at 100 percent.

For additional heat abatement, a soaker line runs above the headlocks. To remove moisture during cold weather, there are nine low-horsepower fans along the barn’s ridge.

The new barn houses five groups of about 180 cows. Though each group pen has only 156 stalls, the farm team feels they are better able to manage through overcrowding in this facility. The existing barns continue to be used, with a portion of the six-row facility dedicated to prefresh and calving.

Cows are content in the stalls, which are bedded with the dairy’s dried manure solids. Wider alleys – 14 feet on the feed alley and 12 feet on the stall alley – give cows room to walk behind their locked-up penmates and make it easier for employees working with these animals.

The initial barn design included alley scrapers, but the dairy’s team decided to use a tractor instead and invested in a wider scraper with arms to span the width of the alleys.

For a herd averaging 98 pounds per cow, they were pleased to maintain high milk production through the transition into the new barn while also noticing improved reproductive performance. “Our repro rates are much better now than they have ever been,” Guenther adds, attributing the progress to giving cows the space and rest they need to actively exhibit heat.

Seven months into the barn at Double S Dairy, Smits is pleased with the project, concluding, “I wouldn’t change anything, but it would be nice if it was one group bigger.” PD

PHOTO 1: After careful consideration, the owners and herdsmen at Double S Dairy decided that a cross-ventilated barn with an adjustable curtain baffle was the right solution for their operation. Pictured are (left) Butch Guenther, herdsman, and (right) Dan Smits, owner.

PHOTO 2: Double S Dairy worked with a roll-up curtain company to install curtain baffles that adjust with a hand crank. They plan to clean the curtains once a year using a large capacity air compressor.

PHOTO 3: The curtains are rolled down in the summertime to direct airflow onto the cows and then raised up in the winter. The design keeps air fresh and allows more natural light throughout the barn.

PHOTO 4: An alley separates the cows from the fans, providing plenty of room for any maintenance work.

PHOTO 5: A total of 58 60-inch fans keep air moving across the barn. An additional 9 fans are located along the ridge to remove moisture in the winter. Photos by Peggy Coffeen.

-

Peggy Coffeen

- Editor

- Progressive Dairyman

- Email Peggy Coffeen