At Paul Dotterer and Sons Inc., modifications made to the holding pen have cows cooler and more comfortable. The 940-cow dairy located near Mill Hall,Pennsylvania, chose to invest in better cow cooling for their holding area last year.

“We figured the biggest bang for our buck was the holding area because it affects all of the cows,” Candice (Dotterer) White says.

White manages the dairy side of the operation, which was started by her grandfather Paul and carried forward by her father, Larry, and uncle John. Together with her sister and two cousins, they represent the third generation to dairy here.

Keeping a close eye on the cows, White noticed that during the warm, humid Northeastern summers, cows were sluggish to move through the holding pen and in and out of the milking parlor.

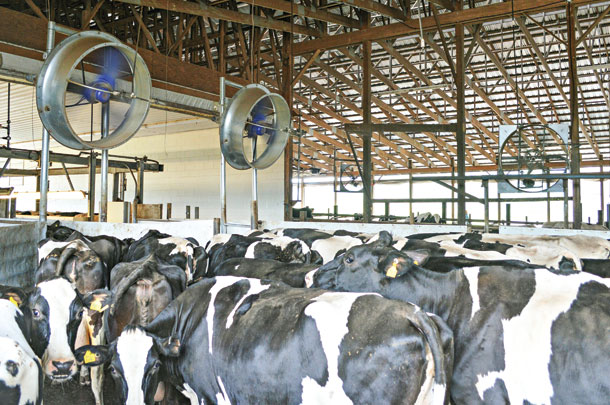

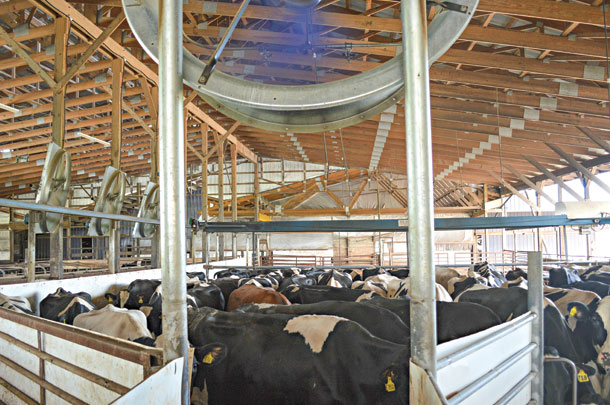

“You could just tell they were hot in there,” she says. Even with a couple of fans at the front of the pen, she knew that the cows were feeling stressed. There was not enough air movement to effectively cool a group of 120 cows in the 80-by-40-foot pen.

With the help of a cow cooling company, the dairy installed an automated cooling system that is proving to relieve heat stress. At the front of the pen, two direct-drive 50-inch fans, each with a 5 horsepower motor, cool cows by moving air at speeds up to 32 mph and 2,800 feet per minute.

The air from these high-power fans can be felt at 5 mph 100 feet out. Misters are also affixed to these two fans. Additionally, there are four 50-inch fans with 1 horsepower motors along the side of the holding area for the purpose of pushing in fresh air.

Throughout the pen, eight sets of drop-down nozzles create a light rain of larger droplets of water to provide relief during extreme heat.

One automatic and intuitive controller operates both the fan and water systems – and is programmed to turn them on in stages during milking times as temperatures in the pen rise. At 55ºF, the two fans in front of the pen turn on at a low level, picking up speed incrementally as temperatures rise.

By 65ºF, these fans are operating at full speed, and at 69ºF, the attached misters kick in, along with two of the four side fans. The 74ºF mark triggers the third fan and the sprinklers, and by the time the pen reads 80ºF, all fans are on and the system is running at full speed.

According to White, the first summer with this cooling system put it to the test. “It was a really brutal summer,” she notes, yet despite the heat, she observed less significant drops in performance. In particular, reproduction was strong for the season.

“Normally, our 21-day preg rate drops down below 15 percent in the summertime,” she says. “This last year, it only dropped down to 18 percent, so we still had the summer drop, but it wasn’t nearly like before.”

Cow behavior also tells White that the animals find the holding pen much more comfortable. “With the old system, cows didn’t want to walk into or out of the parlor, but now, we actually have cows running to the holding pen and parlor because they want to be there,” she says.

One thing White has learned since installing the automated system is that heat stress happens in the holding pen on days when she didn’t necessarily expect it. “I never thought cows might be experiencing heat stress in February,” she says.

On the warmer winter days, when temperatures peak up in the 50s or 60s, the temperature probe in the pen activates the first level of cooling to kick in. White considers this to be a major benefit of the system. “I don’t have to run around looking at the thermometer and turning on fans,” she adds. “It’s nice to have something looking out for the cows.”

Getting the automated sprinklers just right took some observation and tweaking on White’s part. After setting the initial parameters, she watched to see how wet the cows were getting in order to find the balance between spraying enough water to cool the cows and getting them too wet before entering the parlor.

As far as maintenance, the cooling company came out last fall to drain the water out of the system, and they will come back out this spring to get the sprinklers and misters set for the season. In the future, White says they will probably do the fall draining themselves.

With warmer days right around the corner, White now has confidence cows are cooler and much more comfortable in the holding pen. ![]()

PHOTO 1: A true family dairy operation, Paul Dotterer and Sons Inc. includes multiple generations. On the top, from left to right: Doug Dotterer, Kevin Whitehill, Amanda Condo, Candice White and Lori Dotterer Butler. Along the bottom row, from left to right: Larry Dotterer, John Dotterer, and Jean and Paul Dotterer. Photo provided by Candice White.

PHOTO 2: Two 50-inch fans located at the front of the holding pen cool cows with air and misting. The direct-drive fans are set to turn on low speed when the holding area temperature reaches 55ºF, and the attached misters kick in at 69ºF.

PHOTO 3: Along the side of the holding pen, four 50-inch fans push air across the group of 120 cows while they wait to enter the milking parlor. Photos courtesy of Hershey Ag.

-

Peggy Coffeen

- Editor

- Progressive Dairyman

- Email Peggy Coffeen