Regardless of where your farm is located geographically, every dairy can benefit from cooling their cows. Have you reviewed your barn’s cooling system lately? When evaluating or planning the cooling system for your herd, remember the five parts of cooling: SAAWW – shade, air exchange, air movement, water for drinking and water for cooling.

Each piece is equally important to provide relief to your cows. Ultimately, we’ll focus on finding the right kind of water-cooling product for your facility, but it is important to ensure that you are adequately supplying each of the other segments.

SAAWW

Shade is an obvious first step to help minimize the effects of heat radiating from the sun onto cows. Many farms house their animals in barns, but grazing operations must be sure to provide shade (either trees or a structure) for your cows to escape the sun.

When it comes to air, it is important to realize that there is a distinct difference between using fans for ventilation versus cooling.

Air exchange, or ventilation, is replacing stale air with fresh air for breathing, and it is typically measured in volume of cubic feet per minute (CFM). Mechanical or natural ventilation can be used for air exchange. With either system, you should be replacing the air every few minutes.

The focus of air movement for cooling is air speed in miles per hour (mph). In order to have healthy, productive cows, your barn should provide both air exchange and air speed. Cows should have ample access to water for drinking to combat heat stress.

Additional watering areas may need to be added, especially if there is a long walk to and from the parlor. The temperature of the water has little to no impact on its ability to satisfy or cool cows.

Adding water for cooling to your facility is an important step that almost always pays. Evaporative cooling is the most effective kind of cooling. It is the process by which water leaves a surface and enters the air stream. Water (sweat or panting) leaves the cow’s body and takes heat energy with it. When it comes to water cooling, you must decide what features and benefits are best suited for your facility.

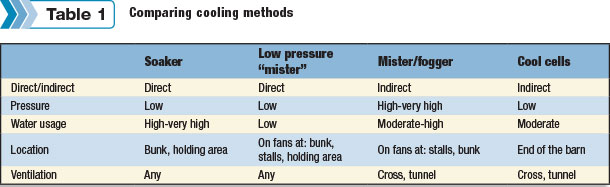

You will want to weigh out these options: direct versus indirect; low versus high pressure; where you want to cool; and the amount of water that you want to use (Table 1).

Direct evaporative cooling

Direct evaporative cooling lowers the cow’s core body temperature by applying water onto the cow and then evaporating it off. Cows have very few sweat glands, so in essence you are creating an artificial sweat for them. The air movement evaporates the water off of the cow and lowers her body temperature.

Think of getting out of a pool on a hot summer day when a breeze is blowing. You will most likely feel chilled and perhaps even have goose bumps. This is direct evaporative cooling.

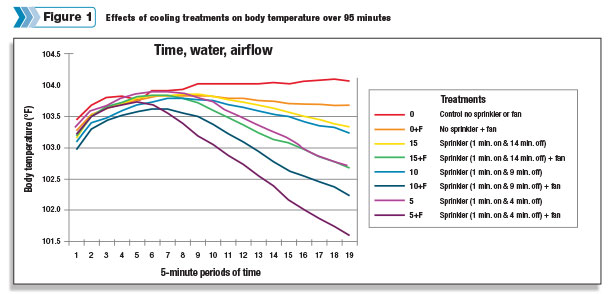

One study conducted in 2003 at Kansas State University shows the relationship between water and air at different time intervals on the cow’s core body temperature. The more frequently that water is applied, in conjunction with fans, the faster the cow’s body temperature returned to normal.

Most direct cooling systems use a large enough droplet that they can run off of well pressure; however some require a booster pump. The amount of water used can vary greatly. Many “soaker” type systems use a heavy flow rate that results in excessive water waste.

In addition to fuller manure lagoons, excess water can mean increased somatic cell counts and soft hooves. Soakers can only be used at the feedbunk.

New direct “misting” technology is also effective at lowering cows’ body temperature while using significantly less water. This option can provide direct cooling over the stalls without getting the bedding wet. Miner Institute President Rick Grant pointed out in a previous article, “a system that could effectively cool over the stalls and the feedline ought to be ideal.”

Indirect evaporative cooling

Indirect evaporative cooling lowers the air temperature in the barn by infusing a mist or fog into the air. The water is evaporated from the air, lowering the air’s temperature and creating a cooler environment for the cows. With indirect cooling, air speed is needed to evaporate the water, but also to move the cool air through the barn.

Cool cells are another example of indirect cooling. With cool cells, water runs through the unit to cool the air as it enters the barn. While it can still have a cooling benefit, indirect evaporative cooling is often less effective than direct because the cow’s temperature is not immediately lowered; the air temperature must be lowered first.

Indirect cooling is often more common in tunnel or cross-ventilated barns rather than naturally ventilated because there is less chance of the cool air escaping. These systems typically require a pump and usually have higher water use.

Maintenance and water quality are very critical in these systems because respiratory problems can quickly arise if bacteria is infused into the air.

Humidity and evaporation

Any kind of evaporative cooling is limited by the amount of humidity in the air. Humidity is the saturation or water content of the air. As water evaporates from your cows, the air around them becomes more saturated (humid). As humidity increases, the rate of evaporation decreases.

The minimum air speed for good evaporation is 5 to 7 miles per hour. The higher the air speed, the more cooling; this can be thought of as the “wind chill.”

For direct evaporative cooling, air speed is extremely important. Fans with lower air speeds need to be spaced closer together so that each cow receives enough air speed to provide evaporation. Indirect evaporative cooling systems are most susceptible to humidity changes because they function by adding more moisture to the air.

Some cooling systems have begun to incorporate temperature humidity index (THI) functions into their controls. As the humidity increases, the systems automatically adjust to optimize evaporation. This feature is especially important in areas that have higher humidity (such as the Southeast).

Remember that the first priority to provide cooling relief is in the holding area. Milking is the most stressful time of a cow’s day, and high temperatures greatly increase that stress. Holding area temperature can quickly rise 15 to 20ºF higher than the ambient temperature.

Sufficient fans and water cooling are essential. Thermostats and other controls can help prevent employees from forgetting to turn on these systems. Studies show that without cooling in the holding area, it can take up to six hours for a cow’s body temperature to recover.

Many of the systems mentioned can be applied to the holding area, and in some cases, it may be beneficial to incorporate more than one kind of water cooling (Figure 1).

All forecasts are pointing to a record-setting hot summer. Help your herd remain comfortable and productive, regardless of the warm temperature. The market has many options, so take the time to find the right fit for your facility. PD

References omitted but are available upon request. Click here to email an editor.

Suzanne Meck works with CowKühlerZ. Email Suzanne Meck.