Most days your automatic scraper system chugs along in the barn, doing its job. Until it doesn’t. Then, it’s an emergency call to your dealer and extra shipping and service fees for replacement parts. All the while manure is building up, impacting cow cleanliness and milk quality.

Does this sound like a nightmare you want to avoid? Implement a scheduled maintenance plan for your scraper system to help keep equipment in top shape and prevent costly breakdowns.

Make maintenance a priority

Maintaining scraper equipment can easily get put on the back burner as other priorities and emergencies come up. A scheduled maintenance plan will ensure equipment is regularly checked to keep your scraper in good working order and help prevent future issues.

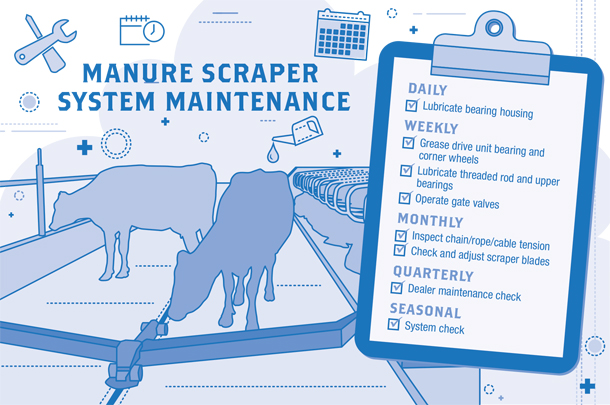

Perform these daily, weekly and monthly maintenance checks to keep equipment running smoothly:

- Lubricate bearing housing (daily)

- Grease drive unit bearing and corner wheels (weekly)

- Lubricate threaded rod and upper bearings (weekly)

- Operate gate valves (weekly)

- Inspect chain/rope/cable tension (monthly)

- Check and adjust scraper blades (monthly)

Don’t overlook the basics

A simple maintenance item every farm should do is greasing. Equipment has never broken down due to over-greasing. The same can’t be said for under-greasing.

Regular greasing of corner wheels and drive units will ensure wheels are turning efficiently and help extend the longevity of your equipment. Use your equipment manual or talk with your dealer to determine the best schedule and type of grease needed for your specific equipment.

Another easy maintenance check is wear and tear of the chain, cable or rope, depending on your scraper system. Regular maintenance and monitoring can help extend the longevity of your equipment. Simple things like running your boot along the cable every month to see if it’s worn or visually checking the chain links can help you catch issues before they become a problem.

Call in the professionals

In addition to your day-to-day maintenance, work with your local manure equipment dealer to schedule regular maintenance checks. Your dealer has experts trained in properly maintaining and fixing scraper systems to know what needs to be done and when.

Regularly scheduled dealer maintenance also means you don’t have to take time out of your busy schedule to maintain manure equipment or have costly tools on hand.

Dealers should be on-farm every three months to perform the following maintenance checks:

- Grease scraper hinges

- Lubricate chain/cable/rope

- Purge air and check oil in speed reducer

- Inspect chain/cable/rope tension

- Check and adjust scraper blades

- Change speed reducer oil (once a year)

While some of these items are also on the farm’s maintenance checklist, your dealer can provide a second set of trained, experienced eyes that can help catch something you might have overlooked.

Watch out for winter

Winter poses an extra challenge for maintaining manure equipment, or any equipment for that matter. Cold temperatures can cause equipment to freeze up or break down if not properly maintained. Scraper system downtime in winter means extra headaches as frozen manure builds up and can’t be removed until it thaws, even after equipment is fixed.

Perform additional maintenance in October or November to ensure equipment is running smoothly and is ready to handle the winter chill. In addition to your regular maintenance schedule, your dealer should complete the following winter maintenance checks:

- Adjust belt tension

- Check anchor bolt torque

- General cleaning, including control panel

- Visually inspect sealed bearings

- Lubricate 1/2-inch threaded rod

- Inspect wheel cleaners

- Increase scraper runtime (equipment should be run more often in winter to prevent it from freezing up)

These checks should also be done post-winter in February or March to ensure everything made it through winter in good shape.

Having a scraper maintenance schedule is an easy guide to ensure everyone knows what maintenance needs to be completed when. Work with your local manure equipment dealer to create a maintenance schedule specifically for your farm. ![]()

Jeramy Sanford is a nutrient and separation specialist with GEA. Email Jeramy Sanford.

PHOTO 1: Keep your scraper in top shape with regularly scheduled maintenance. Photo courtesy of GEA.

PHOTO 2: Graphic by Kristen Phillips.

.jpg?t=1687979285&width=640)