Emission standards for off-road diesel engines are set in the U.S. by the Environmental Protection Agency (EPA). The implementation of the first off-road diesel emissions standards began in 1996 with Tier 1.

Since then, each tier level has continued to limit the amount of pollutants being released into the atmosphere. With the latest emissions requirements, known as Tier 4B or Tier 4 Final, manufacturers are required by law to meet these emissions requirements in the products they sell.

There are a few different after-treatment solutions for Tier 4B off-road diesel engines, and manufacturers use one of, or a combination of, the following systems (most popular): SCR (selective catalytic reduction), DOC (diesel oxidation catalyst), DPF (diesel particulate filter) and CEGR (cooled exhaust gas recirculation). SCR controls the PM (particulate matter) internally by allowing the engine to run as efficiently as possible, then converting the NOx in the exhaust into nitrogen and water vapor by treating it with a urea solution known as diesel exhaust fluid (DEF).

Some characteristics of DEF may be of interest:

- It is classified as minimum risk for transportation because it is nonhazardous, nontoxic, non-flammable and nonexplosive.

- It is heavier than petroleum products, weighing in at 9.1 pounds per gallon.

- DEF will freeze at temperatures below 12°F, but the quality is not affected by the freeze and thaw.

- If DEF is spilled on the tank, a white residue is left behind, known as crystallization.

- DEF will find any crack or leak in the system or lines to escape from, known as “creeping” or “leaching.”

- DEF has the same alkalinity as baking soda and is corrosive to soft metals.

SCR systems are sensitive to potential chemical impurities in the urea solution. To be effective and trouble-free, DEF used in equipment must be high quality and must meet ISO standard 22241. Poor quality DEF can be harmful to an SCR system, potentially causing damage. Flushing and cleaning poor quality DEF out of an SCR system can take a minimum of eight hours (normally two days). Standard 22241 governs quality requirements, test methods, handling, transportation, storing and refilling interface.

American Petroleum Institute (API) Certified Diesel Exhaust Fluid is a voluntary program that certifies and monitors the quality of DEF intended for use in SCR-equipped engines. Their certification mark identifies fluids meeting the performance requirements for proper SCR operation.

Make sure that the transportation used is done via a dedicated fleet to ensure DEF quality. Some suppliers use wash-and-rinse trailers that may have contained milk or other products, leaving residue that could potentially contaminate the DEF. Just 1 teaspoon of salt can contaminate an entire truckload of 5,000 gallons of DEF.

Some tractor owners are now using DEF for the first time. With summer upon us, it is very important to understand the effects of proper DEF storage and the value of high quality DEF.

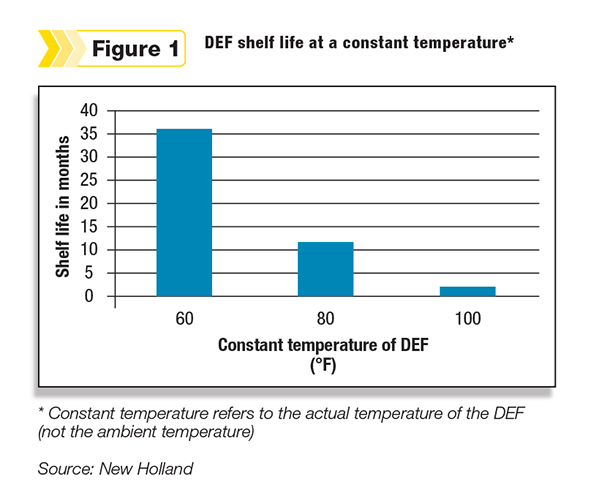

DEF can maintain its quality in storage during the summer months, provided careful attention is paid to the way in which shelf life varies with temperature. It is important to note that the temperatures mentioned here refer to the actual temperature of the DEF fluid, and not the ambient temperature.

The accompanying chart shows how the shelf life decreases as the fluid’s temperature increases. At a constant 60ºF, DEF has an expected shelf life of three years. At 80ºF it has an expected shelf life of one year. At 100ºF it has an expected shelf life of only three months. This difference clearly shows the importance of controlling the temperature of DEF fluid in storage in order to ensure its summertime quality. PD

Alex Booms is a dairy and livestock marketing specialist for New Holland Agriculture.