It’s human nature to love a celebration – whether it’s your favorite sports team winning the big game, a party for a long-awaited engagement or a milestone birthday bash. Why should celebrating major successes on your dairy be any different?

Success can be hard to measure if you don’t track performance. On a dairy, there are many areas where you can capture data to evaluate performance and identify opportunities for improvement.

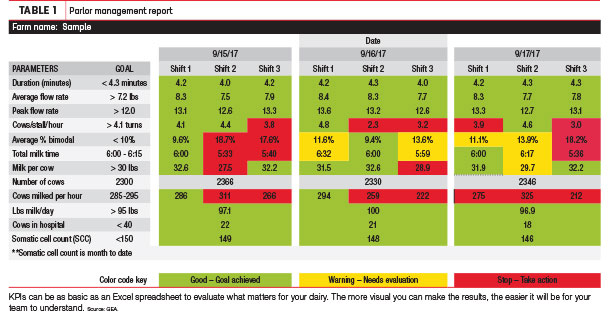

Key performance indicators (KPIs) are a great tool to help you monitor progress. If you already have KPIs in place, consider re-evaluating your goals for each KPI and what you’re currently tracking to determine if an update is needed to meet your goals.

KPIs help you identify where you are, what your trends are and how you’re doing at accomplishing your goals – which is beneficial for any dairy. For example, if you only track your somatic cell count when the milkman delivers it or because it gets emailed to you, it’s like getting a pass/fail grade for a class.

If you use KPIs to evaluate your milk quality, it can help you identify problem areas sooner, allowing you to implement new processes faster. In turn, you can gain efficiencies and improve performance, positively impacting your bottom line. Once implemented, KPIs can be a powerful tool to help take your dairy to the next level.

Use data you already have

Most dairies have a variety of data at their fingertips. It’s up to you to put the information in a form where you can easily evaluate and track your trends over time.

Click here or on the iage above to view it at full size in a new window.

When you think about KPIs for your dairy, look to these core areas: milk quality and udder health, milking equipment and parlor efficiency.

Some great KPIs to assess are:

1. Milk quality and udder health

Somatic cell count is the most basic KPI to track when evaluating milk quality and udder health. Consider the following benchmarks when making your milk quality goals:

-

Bulk tank somatic cell count: Develop a goal that makes sense for you and your dairy, knowing your quality premiums

-

Individual cow somatic cell count: Track the percent of your herd under 200,000 cells per milliliter

-

Percent clinical mastitis hospital cows: Less than 2 percent is a good goal; less than 1 percent is elite

- Lactating cows with new cases of clinical mastitis: Less than 2 percent

On the subclinical side, know your percent infection rate. It’s helpful to look at a breakout by age group – consider 2-year-olds compared to mature cows.

Reviewing rates by age can help you identify if 2-year-olds are calving in with udder health issues. Mature cows are more likely to have a higher rate of subclinical infection, having been exposed to more bacteria in their lifetime.

Don’t overlook the environment and the impact it could be having on your milk quality and udder health. Take ventilation, bedding and housing into consideration. Assess your current level of mastitis-causing pathogens by taking bedding cultures.

2. Milking equipment

Know your pulsation levels and system vacuum settings. Make sure pulsators are graphed and serviced on a regular basis. It is helpful to have a vacuum gauge close to the receiver jars with a posted number of what the system vacuum should be and have milking staff check it every shift.

Milking units and air tubes should also be checked every milking to make sure there aren’t any problems such as torn air tubes or plugged vents.

Keep your equipment technician informed on overall herd health and production level. Also, let he or she know if there have been changes to milking times and times per day, the number of cows in the herd, a liner model or milking system settings. These insights can help your technician determine if your system is working together or needs adjustments.

3. Milking performance

In general, some key areas to assess for milking performance include:

-

Liner slips: Less than 5 percent of all cows (less than 2 to 3 percent on all quarters)

-

Sustained peak milk flow: Achieved within 30 to 45 seconds on 80 percent of cows

- Efficiency: Pounds of milk per stall per hour, turns per hour, total milking time per shift

If the technology of your milking system provides more metrics, considering tracking:

-

Average milking time per cow: Five to seven minutes for 2X milking and four to five minutes for 3X milking

-

Average milk flow per minute: Greater than 8.5 pounds per minute for 2X milking and greater than 6.5 pounds per minute for 3X milking

-

Percent milk in the first two minutes: Greater than 50 percent

- Percent bimodal milk flow: Less than 10 percent for 3X and less than 5 percent for 2X milking

Pick the performance indicators that matter to you and your dairy. Then keep it simple. KPIs can be as basic as a page or two of management sheets or an Excel spreadsheet to evaluate what matters for your dairy. Set SMART (specific, measurable, attainable, rewarding and timely) goals and work from there.

Overall, it’s important to combine little pieces of information and apply them to numbers that matter so you can positively impact your dairy.

Share results, celebrate wins

Most employees will make important what their employers make important. By defining KPIs and how important they are to the farm and their job, it helps with employee performance. Full, transparent communication is key to getting all team members on the same page working toward a common goal. Through regular monitoring of key performance indicators, your dairy’s goal will be very clear to your team.

Share results with your team; they love feedback. The more visual you can make the results, the easier it will be for your team to understand them. Many dairies have color-coded reports they share with every shift. And make sure to celebrate your wins. If reaching goals can make your team feel good, they’ll want to keep achieving more.

Don’t know where to start in creating or re-evaluating KPIs on your dairy? Consult with your milk quality and hygiene specialist. ![]()

-

Keith Engel

- Dairy Farm Hygiene and Supplies Specialist

- GEA

- Email Keith Engel