Exposing forages to anhydrous ammonia can increase roughage intake and digestibility, increase the crude protein content and allow the roughages to retain more moisture by inhibiting mold development, says David Lalman, extension beef cattle specialist at Oklahoma State University.

“The idea is to sort of marinate the hay source in anhydrous ammonia; generally speaking, this improves the digestibility of the hay dramatically,” Lalman says. “When producers ammoniate wheat straw, it essentially improves the quality to the point where it is very similar to prairie hay.”

“Marinating” the hay source can be a difficult task, and producers should ensure they have the ability to effectively and safely work with anhydrous ammonia before considering this process, according to a fact sheet written by Lalman.

Having access to anhydrous ammonia, not knowing the exact weight of the hay and the inability to calculate exactly how much anhydrous ammonia should be applied can all be limiting factors in a producer’s ability to use this process.

After the decision to apply anhydrous ammonia has been made, the hay needs to be stacked so a single sheet of black polyethylene can cover it, with the sheet being 6 mils thick. The stack should be sealed with at least 8 inches of soil, rock or other weighted materials.

Ensuring the structure is completely airtight prevents the loss of ammonia over time. The anhydrous ammonia can be injected slowly into the stack through a pipe or a hose. The amount of time the stack needs to be sealed depends on the temperature, but a minimum of two weeks is suggested. Ideally, the stack should be left covered until two days prior to feeding to allow the excess ammonia to escape.

“The stack needs to be made as soon as possible after harvest,” Lalman says. “The reason being, anhydrous ammonia seeks moisture. If it has been rained on a lot after it’s baled, the exterior of the bale could be wet or have collected a lot of moisture, and the anhydrous ammonia will concentrate in the moisture, resulting in uneven distribution.”

Lalman explains the term “anhydrous” refers to the absence of water. When roughage is exposed to anhydrous ammonia, the ammonia bonds to the water in the roughage to produce ammonium hydroxide, partially breaking down the structure of cellulose and allowing for better access to the fiber of the plant in digestion. The forage should contain a minimum of 10 percent moisture for the breakdown to take place.

This process isn’t always an improvement to the forage and is only recommended in low-quality forages.

“To avoid any toxicity issues, particularly with young calves, this method is not effective for high-quality forages,” Lalman says. “It probably needs to be under 6 or 7 percent protein and in the low 50s or high 40s in digestibility.”

Schallert Brothers Seed Company in Purdy, Missouri, started this process in the early 1980s.

“We do it to improve quality,” says Todd Schallert of Schallert Brothers Seed Company. “We cut fescue seed off of all of our fields, then we go in and cut them for hay.”

Schallert says they just stumbled upon this method but have developed their process enough they are now able to feed between 900 and 950 steers every winter off of the treated hay. Before they began treating their hay, the cattle would eat it but not clean it up because of the difficulty digesting it.

“It makes it more appealing to them also,” says Schallert. “When we feed it, they clean it up just like early cut hay, and we have a lot of success with it.”

Over time, the Schallerts have developed a method of applying ammonia that works best for them. This involves stacking 109 bales with 16 rows of four bales wide on the bottom and 15 rows of three wide on top, covered by a 40-foot-by-100-foot sheet of plastic. Six to 8 tons of lime are poured on the edges to seal the covering to the ground before the anhydrous ammonia is injected.

“We have had a lot of success over the past 30-plus years,” Schallert says. “Taking something that wasn’t very palatable to a calf and turning it into a product we can put gain on them with during the winter months has really been beneficial to us. It fits into our program well, and we can harvest our fescue seed, and it still provides hay high-quality enough to feed for the winter.”

Deciding to ammoniate hay could be an option in years of drought or to offer an incentive to bale lower-quality roughage. Adjusting the process to ensure it fits into the desired system and can be done safely is critical in evaluating whether or not this process is right for you. ![]()

Safety precautions

Remember, anhydrous ammonia is dangerous. If misused, it can burn skin, eyes or throat, can explode and burn, and is maintained under pressure. Suggested safety precautions include:

1. Wear goggles, rubber gloves and protective clothing.

2. Work upwind when releasing anhydrous ammonia.

3. Have fresh water available to wash off any anhydrous ammonia that comes in contact with skin.

4. Check valves, hoses and tanks for leaks.

5. Check plastic cover over stack for leaks.

6. Do not smoke near anhydrous ammonia.

7. Keep children away from treatment area.

Remember, anhydrous ammonia is corrosive to most metals.

—From University of Nebraska – Lincoln EC89-265, “Ammonia Treatment of Low-quality Forages”

Procedure for anhydrous ammonia treatment

The ammoniation procedure is relatively simple and easy to accomplish. The stack of forage must be totally covered and sealed with plastic to make an airtight environment for the anhydrous ammonia to be added into. A few simple steps routinely used to ensure successful treatment include:

1. Determine the amount and approximate weight of residue or forage to be treated in each stack and the availability of plastic in your area. Most farm supply stores and lumberyards sell various sizes of plastic, with the largest being 40 by 100 feet. If possible, locate stacks in an area with some protection from strong prevailing wind, good drainage and near where it will be fed.

2. Disk an area to loosen the top 1 to 3 inches of soil for anchoring the plastic cover. If 40 by 100 feet of plastic is used, blade a space about 15 feet wide and 80 feet long to provide a surface for the bales and loose soil to later cover and seal the plastic.

3. Stack residue to be treated on the smooth area. If big round bales are used, stack them in a triad (two bales on the bottom and one bale on top) or in a pyramid (three bales on the bottom, two bales on the second row and one on top). Size of the bales and plastic dictates the method of stacking. If the plastic is 40 by 100 feet, there is usually enough room for 11 to 13 bales per row. Leave about 2 inches between each set of bales so as much of the bale as possible is exposed to anhydrous ammonia.

4. Cover stacked residue with new 6- to 8-millimeter black plastic and seal the edge of the plastic with the excess loose soil. Leave a small space to insert a pipe for adding anhydrous ammonia about the midpoint of the stack.

5. Insert a pipe 6 to 10 feet in length on the ground at the midpoint of the stack. Seal plastic with dirt around the pipe and connect the pipe to the hose on the anhydrous nurse tank. An adaptor is required that usually can be acquired from the supplier of the anhydrous ammonia. A shut-off valve on the pipe helps eliminate the backflow of anhydrous ammonia when disconnecting the adaptor after treatment is completed.

6. Add 60 pounds of anhydrous ammonia per ton of dry forage.

7. Turn on anhydrous ammonia slowly, until the plastic balloons slightly, then shut off the flow. Go around the stack and check for minor tears in the plastic or leaks around the edges of the stack. If there are tears in the plastic, cover them with duct tape. After checking for and taping any holes, add the remainder of anhydrous ammonia until the desired amount has been added. Do not add anhydrous ammonia so fast the plastic balloons. Total time to treat the residue will be about eight to 10 minutes per ton of residue; a 30-ton stack requires about five hours.

8. Turn off valve after treatment is complete and remove pipe. Reseal the area where the pipe was removed.

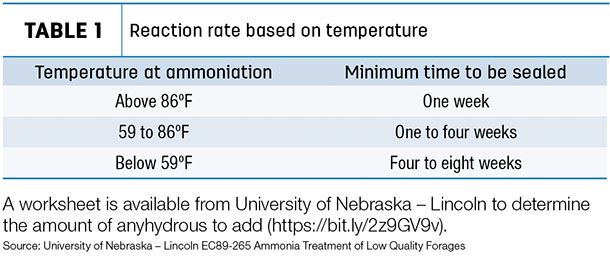

9. The rate at which the reaction occurs is temperature-dependent (Table I). The cooler the outside temperature, the longer the residue needs to remain sealed.

10. Open one end of the stack three to five days prior to feeding to permit dissipation of the remaining anhydrous gas.

A worksheet is available from the University of Nebraska – Lincoln to determine the amount of anhydrous ammonia to add at Ammonia treatment of low quality forages.

—From University of Nebraska – Lincoln EC89-265, “Ammonia Treatment of Low-quality Forages”