As the forage and dairy production industries have evolved, forage sampling/analysis has become integral not only for ration formulation, but also for forage contracting, pricing and inventory control programs used by dairy producers and their consultants.

Because forage quality plays such a critical role on modern dairy farms, traditional forage sampling and analysis guidelines may not be adequate. The aim of this article is to re-think forage sampling and analysis guidelines for dairy farms in a question-and-answer format.

How frequently should the dry matter (DM) content of silages be determined on the farm?

The DM content of silages and wet byproduct feeds must be determined to calculate the as-fed amounts of these ingredients to add to the total mixed ration (TMR) to ensure the desired amount of DM is being fed in the ration.

Because feeding the proper amount of DM of each feed ingredient in the ration is so important, it is recommended the DM content of silages be determined as frequently as possible.

Many farms adopt 1x- to 3x-per- week forage DM evaluation protocols to ensure the proper of amount of silage DM is fed in the ration.

In most instances, weekly or batch sampling of wet byproduct feeds for DM determination is adequate.

In addition, when a change in silage moisture content is noticeable by sight or touch, the DM content of the silage or byproduct feed should be re-determined immediately.

There are some circumstances that may require altering the basic silage or byproduct feed DM monitoring plan listed above.

For example, in bunker silos the silage DM monitoring program is dependent on the variation in DM content at filling, removal rate and whether or not a facer is used to remove the silage.

With minimal variation in DM content at filling (i.e. corn silage), fast removal rates and facer removal, the DM content during feedout is often less variable because DM contents (i.e. varying harvest and drying conditions) are better represented horizontally and vertically along the face of the bunker silo.

With highly variable DM contents at harvest (i.e. legume or legume-grass silages), slow removal rates and unloader removal, the silage DM content during feedout can be highly variable.

As a result, silage DM monitoring programs may need to be intensified depending on the forage and how the silage is removed.

Another consideration is monitoring the DM content of silages stored in silo bags.

Often a set weekly DM monitoring program that works well for corn silage stored in bags does not work well for legume, legume-grass or grass silages stored in silo bags, because silages stored in bags are removed exactly as filled: load to load, field to field or cutting to cutting, with the variation in DM content at filling still present during feedout.

When legume or legume-grass silages are stored in silo bags, it is often better to determine the DM content of silages when filling the silo and marking the bags by load, field or cutting, so rapid changes in silage DM content can be anticipated. This approach can work for other nutrients (i.e. CP, NDF, etc.) as well.

Another simple procedure to determine DM content of silages in bags or tower silos highly variable in DM content is to use a food dehydrator and place a silage sample in the dehydrator after feeding.

The dehydrator will dry the forage slowly overnight and the forage DM content can be determined the following day immediately before feeding.

How frequently should forages be sampled for analysis of nutrient composition at a commercial feed testing laboratory?

Evaluation of forage quality has traditionally been done by monthly sampling of the forages being fed and sending the samples to a feed and forage testing laboratory for determination of nutrient composition.

However, this sampling protocol may be inadequate on larger dairy farms. Researchers at Ohio State University now recommend different feed and forage sampling protocols depending upon herd size.

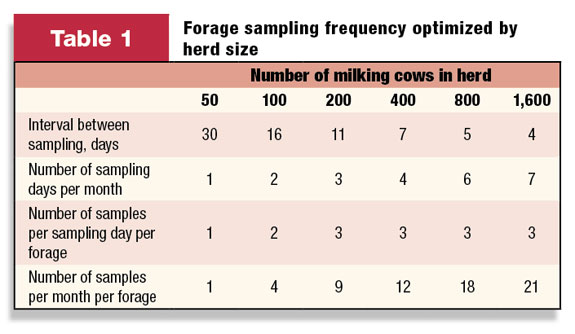

An analysis was performed using their software program to generate the results provided in Table 1 and Table 2 .

The optimum sampling frequency for herds ranging from 50 to 1,600 milking cows is presented in Table 1. The optimum sampling schedule for the 50-cow herd was the same as what has been done traditionally in the dairy industry.

As herd size increased from 50 to more than 1,000 cows, the interval between sampling decreased from 30 to four days, so sampling was required on seven days per month in the large herd instead of only one day monthly in the small herd.

Additionally, the number of samples required per sampling day per forage was one, two and three for 50-cow, 100-cow and 200-cow-to- 1,600-cow herds, respectively.

Therefore, the number of samples required per month per forage increased from one to 21 as herd size increased from 50 to 1,600 cows.

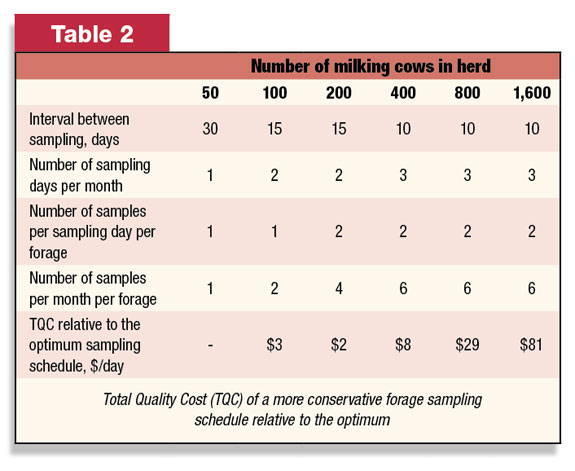

In anticipation of some large herds not wanting to adopt a more aggressive sampling schedule, the results from a comparison of a more conservative sampling schedule to the optimum is presented in Table 2.

For large herds, the interval between sampling was set at 10 days, so the number of sampling days per month was limited to three.

The number of samples per sampling day per forage was limited to two, thereby resulting in six samples per month per forage.

The total quality cost (TQC) to the dairy herd for this more conservative sampling schedule, relative to the optimum, was $8, $29 and $81 per day; TQC includes the cost due to lost milk production if forage quality declines.

The amount of specific forage included in the ration and the potential nutrient content variation can also influence its sampling and analysis frequency.

For example, if a dairy herd is feeding 20 pounds DM per cow per day from legume-grass silage, which has a more variable nutrient composition, then the silage should be tested frequently, as variation in nutrient composition could have a large impact on the ration.

In contrast, if a dairy herd is feeding 20 pounds DM per cow per day of corn silage with low variation in nutrient composition, the silage can be tested less frequently. Likewise, if feeding 1 pound of straw per cow per day, the variation in the quality of straw would have minimal impact on the ration; thus, the straw can be tested less frequently.

Dry hay or straw is best sampled and analyzed on a lot-to-lot or load-to-load basis. The process is different for silages because silo filling, unloading and feeding is a continuous or dynamic process, and silage sampling and analysis should likewise be continuous to determine or anticipate changes in nutrient composition over time.

How should new sample analysis results be used?

An intensive forage sampling program does not mean rations are automatically rebalanced every time a new silage or feed analysis is received from the feed and forage testing laboratory.

Intensified silage sampling protocols are designed to quantify changes in forage quality as early as possible or during the period of change.

If the new nutrient composition results change and there is a logical reason for the change (i.e. change in lot or load, field, cutting, variety, location within the silo, change of silo, etc.), then the new nutrient composition data likely better represents the forage in the current ration. In this case, the new data should be used for ration re-formulation.

If the change in the primary nutrient (CP, NDF, starch, etc.) composition is small (less than 5.0 percent of the old value), the change in nutrient composition may simply be due to random error related to sampling or laboratory analysis.

In this case, the new nutrient composition data should be averaged with the old nutrient composition data and the mean values used for the scheduled ration re-formulation. FG

References omitted due to space but are available upon request.

—Excerpts from University of Wisconsin Focus on Forage newsletter, Vol. 12, No. 3