So far in 2020, there have been many unknowns for the U.S. dairy industry. It’s hard to know what to predict for future milk markets and milk prices. However, one certainty for all dairy farm businesses is the need to know forage inventories and ensuring ample forage stocks are available for the entire herd for next year.

This should be a joint effort between the farm team, nutritional consultant and crop adviser. Ideally, a forage inventory assessment should take place at least every quarter, tracking current forage stocks against usage rates and incoming harvests. However, at a minimum, this exercise should be undertaken at least once per year, after all forages are ensiled.

Where to start:

Key discussion points for a forage inventory assessment will include:

- Total number and type of animals in the herd, plus any changes expected over the coming year

- Forage inclusion rates in the different diets, especially for lactating cows

- How much forage is currently in storage? Do you have corn silage inventory for a four-month “carry-over” (e.g., 16-month supply)?

- Any other crops still to be harvested

- Estimate of “shrink” or waste during forage ensiling and feedout – an honest appraisal is necessary

- Any need to purchase extra forages or non-forage fiber sources

The herd’s forage requirements

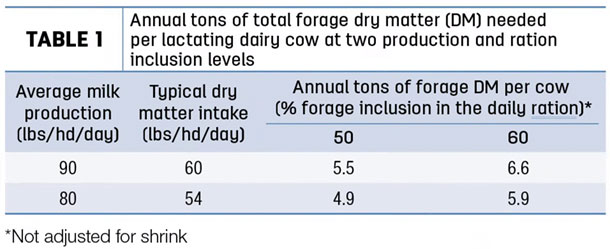

Regarding predicted forage usage, there will be an interaction between herd productivity and desired forage inclusion rates. Table 1 provides the estimated tons of forage dry matter (DM) needed per cow, per year for two levels of milk production and two different forage ration inclusion rates.

Table 1 does not take into account any shrink during forage ensiling or the feedout process, so the annual tons of forage DM would have to be increased accordingly. Even on exceptionally managed forage programs, this can range anywhere from +10% to +20%. Furthermore, at any given milk production level, moving total forage inclusion rates up in lactating cow rations from 50% to 60% increases the annual forage DM requirement by up to 20%.

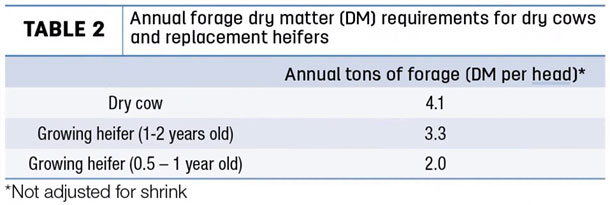

Lactating dairy cows will consume the majority of the ensiled forage stocks; however, there may be dry cows and replacement heifers to consider when making your forage-growing plans. These animal segments are primarily fed high-forage-based diets, and as a tool to help you begin to build your forage inventory budget and growing plan, typical annual forage DM requirements are summarized in Table 2. It should now be possible to calculate the total DM forage inventory needed to meet requirements for the total operation.

Measuring forage inventory

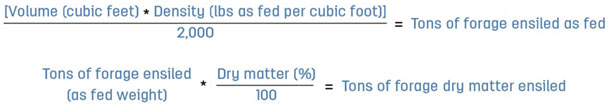

Unless one is only counting baled forage of known weights, the other ensiled forage storage facilities (pile, bunker, tower or bag) require a knowledge of the volume of the ensiled storage structure (cubic feet), typical packing density (pounds as fed per cubic feet) and average forage DM content. You can use the following equations to set up your forage inventory tracking.

If you are unaware of the volume calculations or typical densities, your nutritional consultant and local agricultural university extension services should have information to help with those calculations. Click here for a really useful self-help resource. This easy-to-use spreadsheet can calculate the volume and tonnage for piles, bunkers, bags and tower silos – and help with density values. Decisions can then be strategically made on renting and/or adding more acreage or if raising replacement heifers can be contracted elsewhere more economically.

Working through the herd’s silage requirements and the ensiled tonnage available, be aware of a few important considerations:

- It’s most useful to compare annual forage requirements and availability on a dry matter basis.

- Think about the ratio of haylage stocks to corn silage stocks. While haylage can be fed three weeks after ensiling, there is great feeding and performance benefit to having at least a four months extra carry-over for corn silage stocks. For example, corn silage harvested in the fall of 2020 can be fed in January 2021, further allowing the starch digestibility to increase over this extra time of storage.

- Target the highest-quality forages (digestibility, palatability and hygienic quality) to transition, early lactation and high-yielding lactating cow groups.

- Shrink is a factor on all farms (in all forms during ensiling and feedout). With ensiled forages, shrink can be as low as 10%, but is often as high as 20%. The effect of shrink is you may not have as much edible silage DM to feed out as you think.

- Laser focus should be put on all steps of silage making, management and storage techniques – harvesting at the proper maturity and ensiling at adequate DM, chopping and processing correctly, packing and sealing tightly, and using research-proven silage inoculant technology designed to minimize DM losses in storeage, while enhancing forage digestibility and hygienic quality.

- What are you doing to ensure aerobic stability and palatability at feedout? Research-proven L. buchneri inoculants at 400,000 colony-forming units per gram of forage pay year in and year out.

- How are you supporting cow digestion? Including a rumen-specific active dry yeast probiotic into rations can help manage rumen pH and enhance fiber digestion for improved milk and component yield.

Forage inventory shortfalls

If there is a deficit in the forage inventory, decide how much you need, and make plans for purchasing the extra DM tons required – and make sure you do it early in the season.

Depending on your scenario, it may be as simple as using baled hay or straw (physically effective-NDF) for lower performing cattle to ensure higher-quality silages are available for the more productive herdmates. Alternately, if buying additional ensiled forages from a neighbor is the best option, make sure there is a representative laboratory analysis and that price calculations are done taking forage moisture content into account.

Other feeding options could include adding non-forage natural detergent fiber (NDF) feedstuffs, such as: whole cottonseed, dried citrus pulp, soybean hulls, corn gluten feed, beet pulp, distillers grains and brewers grains. There may also be some regionally appropriate options, like almond hulls or cottonseed hulls. Your nutritionist can examine the best-buy options and inclusion rates for your herd’s specific situation. If nature has thrown you curve ball, and forage inventory is very limited, fear not, it is possible to run successful rations with forage inclusion rates at 40% of total DM intake.

Driving forward

Whatever the economic climate, the need to assess the dairy farm’s forage resources remains a constant priority. Forage inventory conversations are multifaceted, and today’s dairy farm business needs a team approach, including an agronomic and crop expert, along with other advisers who can help obtain the most from owned or rented acres to drive operational and herd profitability.