Big data, machine learning, systems integration and analytics were among the topics covered at the Data Analytics: Current Research and On-Farm Applications meeting hosted at Pond Hill Dairy Research and Development Farm in Fort Atkinson, Wisconsin, May 23.

During the day-long program, leading researchers and graduate students from the University of Wisconsin (UW) – Madison were among those who delved into the current science of dairy data and how artificial intelligence is being used to create decision-making tools for dairy farmers.

What is ‘artificial intelligence’?

Whether they realize it or not, many dairy farmers are already holding artificial intelligence in the palms of their hands. Smartphones, equipped with tools such as facial recognition and text translation, are sophisticated examples, according to Dr. Guilherme J. M. Rosa. As a professor in the UW Department of Animal Sciences, he is leading and overseeing multiple research projects exploring various artificial intelligence applications in the dairy and livestock industries.

“I believe digital agriculture will bring the next revolution for food animal production. Devices such as locomotion sensors and image cameras will gather continuous information on individual animals. This will allow real-time monitoring of herds for disease surveillance and timely intervention,” he said. “In addition, meticulous mining of operational data information from farm software, together with performance information [milk yield, disease incidence, feed intake etc.] as well as other sources of data [weather conditions, economic variables, among others] will provide guidance for continuous improvement of management practices and data-driven decisions.”

On dairies, the umbrella of artificial intelligence covers familiar data-collecting technologies like robotic milking systems, behavior-detecting devices and traceability tools. The next layer is to introduce machine learning tools that combine computer-based algorithms and statistical analysis models, and then use these patterns to perform a specific task.

“All this can be accomplished only with sophisticated machine learning tools such as computer vision approaches to process images and data analytics strategies to extract useful information from such vast collections of data,” Rosa added.

Integrating computer science and animal science

Tasks that once required a human mind are not far from being achieved by what UW’s Dr. Victor Cabrera calls the “dairy brain.” A computer-based system that collects and analyzes on-farm data in real time, the virtual dairy brain uses algorithms to sift through the relevant points in order to produce management recommendations.

Cabrera has been hard at work creating ways for dairy farmers to better use the data they have through grant-funded research projects that integrate the university’s animal science and computer science departments. Data from a group of study farms comes into a central “warehouse” where it is then used to develop models for decision-making tools.

The ultimate goal in creating these systems is to produce practical tools for dairy farmers. UW graduate student Ryan Pralle is trying to teach computers to predict ketosis. His research uses milk spectrum analysis data to predict elevated blood beta-hydroxybutyrate levels. Such predictions could potentially be used to generate shorter lists of animals for cowside blood tests and monitoring.

With a focus on clinical mastitis, Dr. Liliana Fadul is also using machine learning at the university to extract information and make early predictions for the disease. She continues to work to fine-tune the algorithm to be more farm-specific and integrate sensor data with measures like milk production and conductivity for improved accuracy.

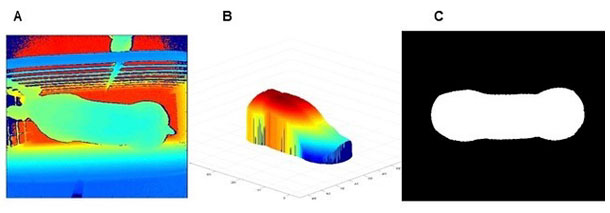

It is also possible to use data to detect calf morbidity by means of computer vision systems and image analysis. At the UW Dairy Cattle Center, Dr. Joao Dorea conducted a project with five group-housed calves to predict behavior based on data from facial recognition cameras. A computer model was able to rapidly classify if a calf was standing, eating or drinking, locate the animal in the pen and then combine calf recognition with behavior recognition to identify changes. Such decision-making tools could be created to predict calf behavior, detect early health issues, predict grain intakes and evaluate social interactions. In another trial, Dorea used 3D cameras to predict calf bodyweight. Model assessments show a positive possibility for this technology to assess weight gain, performance and skeletal development of dairy calves.

This little piggy went to market …

When it comes to precision livestock production, the pork industry is embracing the opportunity to turn data into action for the betterment of the bottom line and animal welfare. With the objective to minimize economic loss, UW student Tiago Passafaro has been using data integration to better understand factors affecting transport losses on market pigs. The model is able to predict losses based on multiple factors, including the plant pigs are shipped to, distance traveled from farm to plant, weather conditions at the time of transport, transportation company and even right down to the individual truck driver.

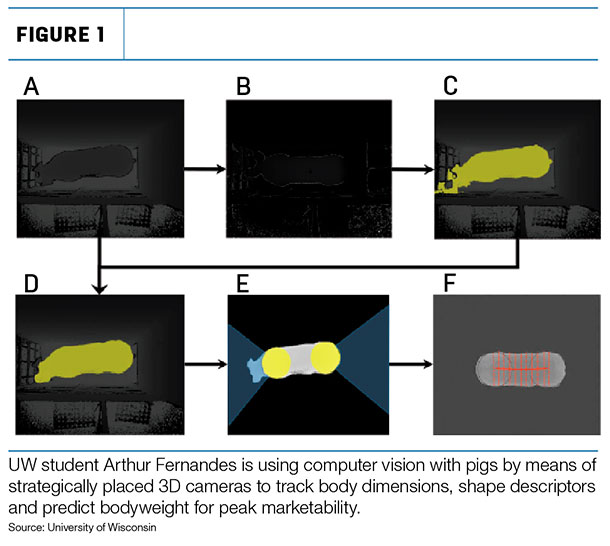

Yet another avenue of AI being explored in pork production is computer vision (Figure 1). Student Arthur Fernandes is using this technology to predict the bodyweight of pigs without actually having to interact with the animal. He used a Microsoft Kinect camera to collect 3D images from which body measurements were extracted. Body volume, area and length were found most informative in bodyweight prediction. Such continuous daily bodyweight predictions can be used then for fine-tuning diet composition according to pig development and also to determine the best timing for marketing pigs.

Potential exists for such aforementioned concepts to cross over into dairy cattle production. UW graduate student Ligia Moreira is currently capturing data points on cull cows from the farm, sale barn and slaughter plant in order to determine the relationship among these factors and how they impact the value of the check the dairy farmer receives for market cows. This, combined with health events and other information from on-farm dairy records software, as well as body condition scores and live weights prior to slaughter, is entered into a software-based statistical analysis approach to determine how these combined factors impact quality, price and value of cull dairy cows.

Knocking down ‘silos’

One of the key challenges Cabrera faces is the current privatization of dairy data. “We have ‘silos’ of data that aren’t linked together,” he said, specifying dairy records companies, genetics companies and sensor technology companies.

His solution: link all the data together. “Let’s make the data a commodity,” and “Let’s incentivize the data sharing in the dairy industry,” he said.

The human health care world has successfully achieved this. For example, the app Strava collects heart rate and activity data for individuals, which is then transferred to health records shared with the Mayo Clinic and used for their research. “Whether we know it or not, all these apps are sharing data,” Cabrera said.

Sharing data for a common purpose has the potential to transform dairying as we know it today. Cabrera went on to predict, “We really think in some way or shape, this will change the way dairy farms operate.”

Rosa emphasizes the value this could have for the individual dairy farmer. He added, “I assure, any farm could benefit from better data storage, processing and analytics to help them in making complex management decisions such as culling, breeding, disease treatment and more.” ![]()

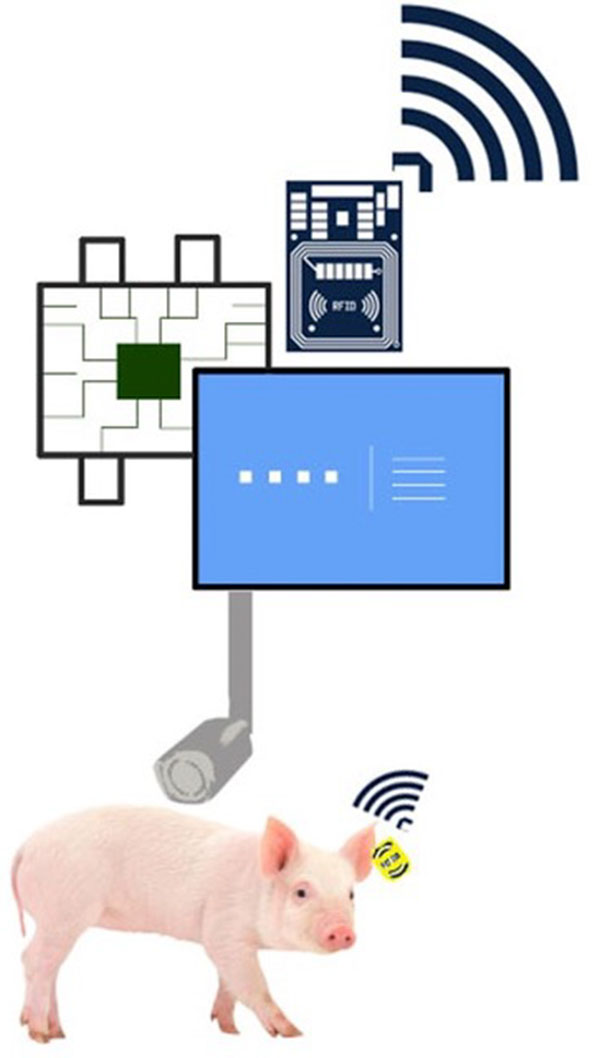

IMAGE 1: Dr. Joao Dorea at the University of Wisconsin – Madison uses computer vision systems to collect images and integrate that with RFID information and other animal health data points.

IMAGE 2: In a research trial, 3D cameras collect pigs’ body measurements like body volume and area in order to accurately monitor growth and weight. This information is used to fine-tune nutrition and determine the optimal age for marketing.

IMAGE 3: Computer vision is an artificial intelligence method that can used in the pork industry to monitor individual animals. Computers are taught, for example, to extract information from animals' images to accurately predict their bodyweight and health status. Images courtesy of University of Wisconsin – Madison.

-

Peggy Coffeen

- Editor

- Progressive Dairy

- Email Peggy Coffeen