Until recently, these were relatively sensitive, large laboratory instruments that required finely-ground, dry forage samples for analysis. New technology has allowed the development of small, hand-held NIR units that can work with wet, chopped forage or silage.

What is NIR spectroscopy?

Light from a spectrometer is either absorbed or reflected off a sample. By evaluating the spectra (wavelengths of light reflected), the instrument can relate the spectra to the known laboratory quality values for a particular sample. A representative group of samples with known quality values is scanned and used to calibrate the instrument for a particular type of sample (e.g., corn silage).

When a sample with unknown quality values is scanned, the calibration equation predicts the quality of the sample. All NIR results are predictions based on calibration equations or algorithms. As long as the calibration sample set is representative and robust, the predicted values are likely to be accurate.

Portable NIR units

Research studies have documented that forage or silage significantly changes in composition from day-to-day, particularly the dry matter (DM) composition. Daily adjustments to reduce variability between formulated and delivered rations has the potential to either increase dry matter intake and increase milk production or to significantly reduce feed costs. Multiple scans with a handheld NIR will provide a more representative sample for analysis and will also assess variability in a forage lot.

Handheld, on-farm instruments and laboratory NIR instruments have three major differences.

- The technology must be redesigned in a much smaller package for handhelds.

- The software must deal with the relatively high moisture content of samples (vs. dry samples).

- The scanning procedure must be modified to account for relatively large particle size (chopped or whole hay vs. finely ground samples).

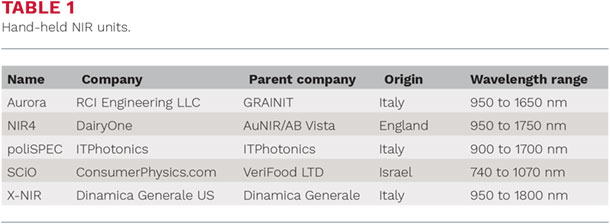

At least five companies produce handheld NIR units that potentially can be used with forage/silage crops (Table 1).

All were developed outside of the U.S. All are sold in the U.S., with the exception of the poliSPEC, which can be purchased in Canada. All were developed primarily to focus on forage crops, with the exception of the SCiO, which was developed for much broader use. Stratio (a U.S. company) will release a small unit somewhat larger than SCiO (LinkSquare-SWNIR, 800 to 1600 nm) in early 2020.

All units are basically a miniaturized version of a laboratory NIR instrument, with the exception of the SCiO, which has a solid-state spectrometer on a chip. All units have an occasional or more often regular requirement to be standardized with a reference or check scan.

All hand-held units have an onboard computer to process spectra and generate results, with the exception of the SCiO, which transmits spectral data to a cell phone, with data analysis on the web. The Aurora and SCiO are all being evaluated for plant breeding selection purposes because they allow user calibration.

Frequently asked questions

Are these portable units robust enough for on-farm deployment?

Small NIR units have been shown to be robust enough to be mounted on field harvesting equipment, so it is likely that hand-held units can be developed that are sturdy enough for on-farm use.

Are these NIR units capable of sufficient accuracy with wet, chopped samples?

Accuracy of lab NIR units has historically been based on having a dry, finely-ground forage sample, which maximizes the uniformity of the sample exposed to the NIR light source. Wet, chopped forages are much more difficult to analyze accurately. The sample area actually analyzed by a handheld NIR is less than 0.5 inches in diameter. Chopped forage has individual pieces much larger than 0.5 inches.

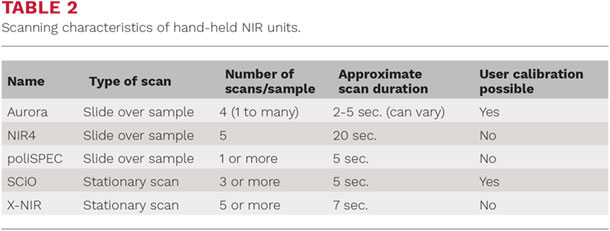

Particle size is addressed by either increasing the number of scans per sample and/or exposing the NIR to a larger area per scan or by moving it over the sample during the scan (Table 2).

While moving the NIR light source over the sample during scanning increases the area analyzed, it also increases the possibility of external light interfering with the spectral data collected.

Are calibrations either specific to your region, or sufficiently global, to provide reasonable results?

To-date, most calibrations for handheld NIRs have been developed outside of North America. Companies are in the process of developing forage quality calibrations that are more specific to North America. Samples analyzed by any NIR need to come from the general population of samples that was used to calibrate the instrument. If a farmer’s sample is outside the range of the calibration sample set, values generated by the instrument may be unreliable.

Which forage constituents can be analyzed accurately?

The relative accuracy of NIR for evaluating forage constituents is generally:

DM (or moisture) > CP > NDF > ADF > ADL > IVTD > NDFD

The range in accuracy among constituents is mostly due to the degree of variability in laboratory determinations. Lab digestibility measurements will always be less precise than chemical analyses. It is unclear at this time whether handheld NIRs will be sufficiently accurate enough to evaluate digestibility or fiber digestibility.

Testing in New York

We obtained the Aurora, the NIR4, the SCiO, and the X-NIR for testing in New York and hope to clarify the potential of instant, real-time nutrient analysis of forage to be rapidly incorporated into farm management decisions. Range in cost is from less than $1,000 to over $20,000 for the instruments, typically with annual contracts for maintenance and calibration updates of several thousand dollars.

If these units can significantly reduce day-to-day variation in ration composition even the most expensive units have the potential to pay for themselves in a year or two, depending on herd size. As this is not an example of “size-neutral” technology, the number of cows in your operation will factor into the economic feasibility of on-farm, handheld NIR. ![]()

PHOTO: Handheld NIR units range in size and operational procedures. Photo courtesy of Jerry Cherney.

Jerry Cherney is a soil and crop sciences professor. Email Jerry Cherney. Debbie Cherney is an animal science professor at Cornell University. Email Debbie Cherney.

This article appeared in PRO-DAIRY’s The Manager in March 2019. To learn more about Cornell CALS PRO-DAIRY program, visit PRO-DAIRY Cornell CALS.