Peter Gould, general manager, Dairy Farmers of Ontario (DFO), presented on the six biggest policy factors affecting the Canadian dairy industry at the PDO Triennial Symposium on March 23 in Toronto.

The six factors included the EU-Canada Comprehensive Economic and Trade Agreement (CETA), the Trans-Pacific Partnership (TPP), diafiltered milk, aging drying facilities, the national ingredient strategy and the Ontario ingredient strategy.

At the time, the two trade agreements were moving through the respective processes for ratification by the countries involved; meanwhile, the Canadian dairy industry was working on its own to solve the issues of increasing imports of diafiltered milk and the aging milk-drying facilities struggling to meet the needs of the industry.

Ontario was about to introduce an ingredient class, and dairy farmers were talking about doing the same on a national scale.

What impact has the ingredient strategy had on the industry since it was put into effect?

“DFO introduced an ingredient class on April 1, 2016. Implementation went as smoothly as could have been anticipated.

“In June, all 10 provinces agreed with processors to a national ingredient strategy. Other provinces are working towards implementation, with completion targeted for early 2017.

“One byproduct of an ingredient strategy was expected growth. However, we are currently experiencing unprecedented growth. With the November increase of 3 percent, producer quota will have increased by 13 percent in just two years, which is not all attributable to the ingredient strategy.

The blend price has been somewhat volatile but should settle down in the new year. Much of the variation has been due to world prices.

“The challenge of keeping up with demand has been partially addressed through butter imports. Producers need to understand the fastest way to a quota increase is through imports. Attitudes need to change in that regard.

Also, somewhat ironically, as quota continues to increase, more barns are getting closer to or have reached capacity. Some producers are going to have to make some tough decisions.”

—Peter Gould, general manager, Dairy Farmers of Ontario

Read the Story: An update on Canadian dairy trade and ingredient processing

2. Sterkholm Farms emphasizes excellent calf care

Published online March 2016, reprinted below

Sterkholm Farms Ltd. encompasses 350 cows on two dairies with 1,900 acres, a veal operation, a custom field-work business and a seed company.

Ben and Marian Sterk and their sons, Mark and Bernie, are involved in the farm and manage daily operations with the help of five full-time employees. The Sterks abide by the philosophy, “Calves are the future of the herd and therefore have the most potential milk production.”

They recently built a new group-housing calf facility and converted a swine facility for raising heifers and veal calves.

Did you use sand bedding in your calf barn again this summer?

“The answer is no. While it had its benefits of flies and keeping the calves cool, sand bedding also has some drawbacks. The major one was high-traffic areas would become wet, and we would be unable to get them dry even with a thick layer of fresh sand.

This resulted in using a lot more sand than anticipated and put cost similar to straw bedding. But we are happy we did some out-of-box thinking.

“At the time of our tour, we milked just over 300 cows. Now, with the purchase of a second dairy farm and increases at home, we milk just under 500 cows, but our calf barn has felt very little effects of this.

We are very glad we built a barn to be labour- and cost-efficient and focus on calf health. After all, these calves are my future milking herd.”

—Mark Sterk, dairy producer, Sterkholm Farms Ltd. and Sterkview Dairy Ltd.

“One of the reasons we [switched back to sand] was that the calves walked enough sand over the curb on the scrape alley, and our calf barn person found it hard to clean up. [With straw], we found that we had a lot more fly pressure in the barn. If we had to change the barn, I would make the scrape alleys skid steer-accessible.

“We are feeding all milk replacer this year due to the extra demand for milk. We are medicating this and the calf issues are a lot less.”

—Ben Sterk, dairy producer, Sterkholm Farms Ltd. and Sterkview Dairy Ltd.

Read the Story: Sterkholm Farms emphasizes excellent calf care

3. Halarda Farms uses calendar system to manage cows, robots

Published online June 2016, reprinted to the right

Anton Borst and his wife, Cheryl, own and run the 800-cow, 4,500-acre and 80-head Angus/Angus-cross operation in Elm Creek, Manitoba, with their nine children.

Of the 800 cows, they milk 770 of them with 14 robots; only their fresh and sick or treated cows are milked in the parlour.

Proper management is crucial to keeping everything running smoothly, so they recently instituted Monday morning meetings where employees report on their area of responsibility and their priorities for the week.

In addition, major tasks are always scheduled for a certain day of the week. This helps keep things organized and up-to-date. For instance, every second Tuesday is vet day, Wednesday they move cattle, Thursday is hoof trimmer day, and Friday is dry-off day.

The robots are checked and cleaned twice a day. Once a week, the herdsman does maintenance on the robots and makes any minor repairs. If a robot has a more complicated problem, either Borst or his brother, Ralph, will look at it and fix it if they can.

Over the last several years, he and his brother have learned how to do a lot of the work themselves and keep some parts on hand, so it’s not uncommon for them to have a month go by without a service call.

What are the typical robot parts you prefer to keep in stock on your farm?

“We stock all regular maintenance items like liners and brushes, and we will basically stock any item that has failed because our dealer is one-and-a-half hours away. If at any time we have to go to the dealer for a part, we will evaluate why, and we will usually start stocking the item we are picking up."

"With 14 robots in operation, it is fairly easy to justify having a larger parts inventory to minimize downtime on the robots.”

—Anton Borst, dairy producer, Halarda Farms Ltd.

Read the Story: Halarda Farms uses calendar system to manage cows, robots.

4. How I stay ‘progressive’ with a 50-year-old tiestall barn

Published online January 2016, reprinted to the right

Tim May of Mayhaven Farms is a dairy producer in Rockwood, Ontario. He is active on social media and provided Progressive Dairyman with a blog about what being progressive means to him.

He wrote, “Being progressive doesn’t always mean getting bigger, and it definitely doesn’t mean you need to spend a lot of money on a new facility or fancy equipment. In fact, the term progressive is defined as ‘developing gradually, or in stages.’

"Perhaps you are happy with your current barn and milking system, or maybe you aren’t even in the financial or personal position to build a new barn.”

May went on to share various ways dairy producers can be progressive no matter what herd size or type of facility they are operating.

What is one way you progressed your farm this past year?

“Beautiful new barns have been popping up all around me this year. I couldn’t help but visit a few of them, and I’d always come home with barn envy. A barn makeover was the cure I needed. I splurged with a professional power washing,"

"I had the roof and exterior walls painted, and I made use of a government grant to update the lighting. Sure, it’s still a 54-year-old barn, but it looks like the day it was built and it’s much more enjoyable to work in. A lot of milk has been produced in this old barn, and I look forward to having the cows produce many more litres in it.”

—Tim May, dairy producer, Mayhaven Farms

Read the Story: How I stay 'progressive' with a 50-year-old tiestall barn

5 Automated system frees up feeding time for Gietemas

Published January 2016

Whatcom Acres Farm is a family-run operation near Abbotsford, British Columbia. Harvey and Brigitte Gietema are the owners, but most of their six children are involved in some capacity.

The Gietemas milk about 200 Holsteins three times daily using a double-12 parlour. The cows are housed in a freestall barn. A second barn houses heifers and dry cows, and provides storage space.

In the spring of 2015, Harvey installed a new automatic feeding system that travels around the barn every 45 minutes. The automatic TMR works out of a “dairy kitchen” where all feed ingredients – silage, grains and dairy supplements – are located.

The amounts of each ingredient needed are loaded according to the recipe used for each feeding group.

As it travels through the barn, it also pushes up feed for easy access by the cows. It feeds on demand, multiple times each day, ensuring there is always fresh feed available to the cows.

Harvey states, “The main reason for buying the [feeding system] was to take the job of feeding from an ‘every day at a certain time of day’ job to a job that can be fit into your day – managing the [feeder] can be done at any time of day."

"It can run for three days without being refilled, so weekends off are possible, and feeding can be managed to free up days for field work.”

Read the Story: Automated system frees up feeding time for Gletemas.

6. Why I chose robots: Danensview Farms

Published December 2015

Coming up short on heifer space, Jack and Jane Danen determined it was time to build a new barn at their farm in Tavistock, Ontario.

“We didn’t mind it at all,” Jack Danen says of his old parlour, “but we wanted to get out of the existing freestall barn. We needed more space, so we built the new barn for cows.”

Heifers and dry cows now reside in the old barn, while the 85 milking cows have exclusive use of the new three-row freestall barn.

After looking at a number of automatic milking systems, they opted for a multi-box setup. Currently, there are two stalls used for milking with the option to expand to a third stall.

They started up their robots last December. After working with them for a while, Danen says, “I like the flexibility it provides. I didn’t pick it for less work but more flexibility in time. The work is different, but I’m not in the barn any less.”

At the time Progressive Dairyman visited last fall, the farm’s SCC level had spiked to 300,000 to 400,000 over summer, and the Danens were working with their veterinarian to troubleshoot the issue.

Did you find the reason for the SCC rise last summer?

“We think we did find the source of the spike in SCC. A number of air bleed holes on the teat cups were plugged. This created a backflow of milk to the teat ends, which in turn resulted in more incomplete milkouts and more kickoffs.

It is part of my routine now to check the holes to make sure they are clear. It took a number of months to get the SCC to return to normal, as we had to work with those cows that developed a high SCC, either through treatments or early dry-off.”

—Jack Danen, dairy producer, Danensview Farms

Read the Story: Why I chose robots: Danensiview Farms

7. Best time to pair-house calves? As soon as possible

Published November 2015

Recent findings on pair-housing calves was shared by researchers at the University of British Columbia. It showed pair-housed calves have reduced behavioural responses to weaning and improved performance when mixed with a larger group after weaning.

Housing young calves with an older, weaned companion further stimulates feeding behaviour and growth before and after weaning.

Calves paired at birth ate more in their first 10 weeks than the individually reared and late-paired calves. They also showed significantly higher average daily gain over the experimental period: around 900 grams per day (about 2 pounds) versus 750 grams (about 1.6 pounds) per day for the individual and late-paired calves.

Is pair-housing calves beneficial even if it cannot be done right away?

“Pair- or group-housing of calves during the milk-feeding phase reduces the age at which calves have contact with other calves and gives them behavioural and performance advantages because they are quicker to discover and consume solid feed, and they transition better into groups after weaning.

However, group size should be no more than 12 calves to prevent disease spread.

“Calves can be successfully grouped at a week or less old if managed properly, but this may not be possible on every farm. There were no differences in solid feed intake and weight gains between calves paired at birth or at 3 weeks old, but both were increased compared to individually housed calves and calves paired or grouped at 6 weeks old."

"Currently, research indicates that calves should be grouped early, ideally within the first three weeks of life.”

—Joao H.C. Costa, University of British Columbia

Read the Story: Best time to pair-house calves? As soon as possible.

8. Bridon Farms adjusts for added comfort, efficiency

Published online, reprinted to the right

Bridon Farms in Paris, Ontario, is a family operation, including Brian Sayles and his two sons, Bruce and Jeff. Since there is no hired labour, when it came time to make changes on the farm, efficiency and cow comfort were high priorities.

They opted to build a free-traffic, compost-bedded pack barn with two automatic milking systems and an attached calf facility.

The new barn has a large compost-bedded pack on one end, and on the other side of the automatic milking systems is a set of smaller, straw-bedded pack pens that are used for show cows, fresh cows and any other animals they want to separate from the main herd.

Have you changed your breeding philosophy to have more ‘robot-ready’ cows?

“We have not changed our breeding program. We continue with our same breeding philosophies of type and production but continue to monitor how they perform in the robotic situation. A sound, complete cow seems to do well in this environment.”

—Bruce Sayles, dairy producer, Bridon Farms

Read the Story: Bridon Farms adjusts for added comfort, efficiency

9. Manitoba dairy farm achieves record milk production with robot

Published August 2016

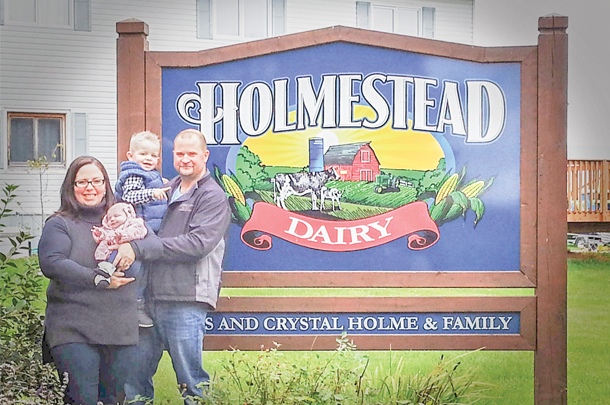

In a press release from DeLaval, it was announced Holmestead Dairy of Anola, Manitoba, achieved record milk production with its automatic milking system shortly after transitioning from a double-four milking parlour to the robotic milking unit.

Holme’s herd of 53 Holstein cows adapted well to the robotic milking system, installed in March of this year, and hit an average of 58.7 kilograms of milk per cow in one day, with one cow achieving 94 kilograms of milk.

Before the robot, Holmestead Dairy was producing an average of 38 litres per cow per day in their conventional parlour.

In addition to the robots, what may have contributed to your farm’s increase in milk production?

“We weren’t doing anything special at the time. Everything was just going right. We are hanging around a 44-litre average now (in early November) but should be back in the 50s in about a month again.”

—Russ Holme, dairy producer, Holmestead Dairy

Read the Story: Manitoba dairy farm achieves record milk production with robot

10. Circle or straight: Is a rotary parlour right for you?

Published March 2016

If you are considering which type of parlour to install, Steve Mattox with DeLaval offered up some reasons why a rotary parlour may be the optimal choice, regardless of herd size.

“Whether your objectives are cow comfort, ease of operations, return on investment or all of the above, rotaries can and do have a place in the industry. Cows like to go for a comfortable ride, relaxed and at their own pace, which equates into improved productivity,” Mattox wrote.

For ultimate success in a rotary, producers need to pay attention to traffic patterns, distance to the parlour and use of crowd gates.

What elements are key for good cow traffic with a rotary parlour?

“Rotary parlour efficiency is dependent on good traffic patterns, which start with design and layout of all lanes to and from the parlour. Much like highways today, we do not travel in single traffic lanes.

If we did, there would be too much stopping and starting to get to our destination on time. Traffic lanes for cows should be designed in the same manner. When we let cows travel in their lanes, by keeping people from interfering and pushing them, each one travels at her own speed and pace.

Some cows like to burst down the highway, while others want to enjoy the scenery. Imagine 500 people at a traffic light waiting to go when it turns green. A qualified dealer should be able to discuss design options to establish proper traffic patterns to make for a more enjoyable and safer task for cows and people.

This helps eliminate stress even before startup, which could possibly increase production.”

—Steve Mattox, marketing manager and project development, DeLaval

Read the Story: Circle or straight: Is a rotary parlour right for you?

11. Team up to tackle these 7 areas of calf care

Published April 2016

Helping producers maintain optimal herd health, Jodi Wallace, a veterinarian with Ormstown Veterinary Hospital, offered seven areas to focus on when it comes to calf care.

“Young calves have fragile immune systems and should be given top priority on the farm. The key to calf health is attention to detail and consistency,” she wrote.

The seven points she mentioned include transition cow health, calving, colostrum management, calf processing, feeding milk, housing and recording health data.

If you were to pick one of the seven areas to focus on first, which one would it be and why?

“The one point out of the seven that would be the most important is colostrum management. What producers do to the calf in the first few hours of life will affect the rest of the calf’s life. Calves are born without antibodies from their dam. W

e must be vigilant to provide calves high-quality colostrum as soon as possible and enough (3 to 4 litres) to ensure the passive transfer of immunoglobulins (antibodies into the calves’ blood system). This is their baseline protection against disease (for example, pneumonia and diarrhea).”

—Jodi Wallace, veterinarian, Ormstown Veterinary Hospital

Read the Story: Team up to tackle these 7 areas of calf care

12 Poly-C Farms’ new barn promotes calf health

Published November 2016

When Cor and Cathy Haagsma, owners of Poly-C Farms in Ponoka, Alberta, built their calf barn in 2015, they strongly considered installing automated feeders. However, they and their employees decided they would miss out on visual contact and inspection too much during feeding calves to make the switch from buckets to auto-feeders.

In addition, since the bottle calves still need to be fed and the auto-feeder needs to be cleaned daily, they felt that the time savings would be minimal. Their solution: a new four-room, all-in-all-out calf barn with individual pens and no automatic feeders.

Overall, they’ve been pleased with the new barn. Cathy says it has accomplished their two main goals in building it, which were to create a better working environment for their employees and a better living environment for their calves.

The calves are no longer subject to large variations in temperature and weather conditions. She says the drop in the calves’ stress levels was the biggest thing she noticed with them.

If you could make one change to your calf barn, what would it be?

“At this time, we wouldn’t make any changes. The barn is still performing as expected. We would like to perform some smoke tests once it cools down to fine-tune the ventilation system.”

—Cor and Cathy Haagsma, dairy producers, Poly-C Farms

Read the Story: Poly-C Farms' new barn promotes calf health

13. The future of dairy: Things, robots and Big Data

Published February 2016

With a growing global population, today’s governments and farmers are looking to increase yield and drive efficiencies. To do so, they are turning to technology for help.

According to futurist Nikolas Badminton, the following three areas will change the dairy industry: the Internet of Things, autonomous systems and Big Data.

“Going forward, we will see more farming data services in the dairy industry which specialize in security, control, analysis and expertise in the systems that use and generate data within the herd and in the fields,” Badminton wrote.

“Farmers will even hire data scientists as the farm becomes a place where technology replaces the farmhands. There will also be the opportunity to make the cattle and dairy production process transparent and the supply chain more optimized to drive greater yield and profits,” he continued.

Name a few things farmers should consider before adopting a new form of technology.

“Before investment, you have to define the need and then see if a new form of technology fits into the frame of the solution. Salespeople will spin return-on-investment stories to close the deal. Demand to speak to others that have implemented it and see greater operational capabilities and a good level of return on investment.

Look for a minimum of two times the initial investment. Also, ask about the upgrade path and the shelf-life of what you implement. You can then plan for the next three to five years accordingly.”

—Nikolas Badminton, world-respected futurist speaker based in Vancouver, British Columbia

Read the Story: The future of dairy: Things, robots and Big Data

14. Strategies for successful calf weaning

Published November 2015

As more and more dairy producers have adopted elevated calf nutrition programs by feeding high levels of milk or milk replacer to maximize pre-weaning growth, health efficiency and future milk production, it has become equally as important to employ management strategies to balance intake of nutrients from milk and solid feed to promote adequate rumen development by weaning.

In determining the success of a weaning program, Amy Sova with Grand Valley Fortifiers wrote, “You can’t truly evaluate your weaning program unless you measure and monitor calf growth rates.

A good idea is to follow a group of calves from birth to weaning and track weight with a growth tape at regular intervals. This will allow you to find gaps or opportunities for increased average daily gain during the pre-weaning stage.”

Would you follow up with a weight check post-weaning?

“Yes, it is important to monitor and assess your heifer growth after weaning to make sure you meet growth targets. Your goal for heifer growth post-weaning should be 0.9 to 1 kilogram average daily gain.

Assuming a typical weaning program (40 kilogram birthweight, 80 kilogram bodyweight at 56 days old), heifers should be able to triple their birthweights by approximately 100 days old with that rate of gain.

“Ultimately, the goal of raising heifers is to get them to adequate breeding size by 12 to 14 months old so you can calve them into the herd by 22 to 23 months old. With lower average daily gain in the post-weaning period, age at first calving will be delayed and herd potential milk yield may be lower.

Tripling birthweight by 100 days should be easily attainable with a proper weaning program and a smooth transition to a new diet and environment.”

—Amy Sova, associate dairy nutritionist, Grand Valley Fortifiers

Read the Story: Strategies for successful calf weaning

15. Can maternal colostrum prevent diarrhea cases in calves?

Published November 2015

Diarrhea caused by Cryptosporidium parvum (C. parvum) is a common condition observed in calves between 1 and 4 weeks old. Without any licensed drugs to treat C. parvum-associated calf diarrhea in the U.S. or Canada, it is important to take steps towards prevention and control of cryptosporidiosis in calves.

One method of prevention is to ensure calves receive adequate passive transfer immunity.

Manuel F. Chamorro, with Saskatoon Colostrum Company Ltd., wrote, “It is possible that supplementation of maternal colostrum, milk or milk replacer with colostrum replacer powder could increase the concentration of specific antibodies against C. parvum and further prevent infection and disease.”

What are the recommended rates for supplementing with colostrum replacer?

“Results from some studies indicate that there is reduction of morbidity and mortality in dairy calves older than 1 day (gut closure) that receive a colostrum or plasma-supplemented milk or milk replacer ration.

In a study in 2009, researchers supplemented dairy calves during the first 14 days of life with 70 grams of colostrum replacer powder twice daily and demonstrated reduction in days of diarrhea and antibiotic use.

Most recently, we performed a study where 150 grams of colostrum replacer powder was supplemented to dairy calves and reduction of enteric, respiratory and umbilical disease was observed along with reduction in overall antibiotic use. These results will be published in the Journal of Dairy Science shortly.” ![]()

—Manuel F. Chamorro, Technical Veterinary Adviser, Saskatoon Colostrum Company Ltd.

References omitted but are available upon request. Click here to email an editor.

Illustration 1: Canadian map. Illustration by Corey Lewis.

PHOTO 1: Ben Sterk, left, and Mark Sterk, right, discuss their calf care routines. Photo by Karen Lee.

PHOTO 2: The Borst family uses 14 robots to milk 770 of their 800 cows. The other 30 are milked in the parlour. Photo provided by Halarda Farms.

PHOTO 3: Some paint and new lighting has Tim May’s barn looking nice and new again. Photo provided by Tim May.

PHOTO 4: Harvey and Brigitte Gietema run a family dairy farm near Abbotsford, British Columbia. Most of their six children are involved in the farm in some capacity. Here, Harvey (second from left) is pictured with his children, Rachel Gietema (left) and Daniel and Jolene Gietema with their baby Harvey Jr. (right). Photo provided by Whatcom Acres Farm.

PHOTO 5: The new freestall barn at Danensview Farms is bright and airy with ample room for the milking cows. Photo by Karen Lee.

PHOTO 6: In much of our work at UBC, we have kept calves in the smallest group possible – a pair. We recommend that producers interested in trying grouping on their farm start with pairs or triplets, using animals that are most similar in age. Photo provided by Joao H. C. Costa.

PHOTO 7: Bruce Sayles explains how the farm manages its compost-bedded pack to a group of visitors on the Progressive Dairy Operators’ Canada’s Outdoor Farm Show bus tour in 2015. Photo by Karen Lee.

PHOTO 8: The Holme family at their dairy in Anola, Manitoba, has achieved record milk production with their robotic milking system, which was installed in March. Photo courtesy of DeLaval.

PHOTO 9: In rotary parlours, cows like to go for a comfortable ride, relaxed and at their own pace, which helps to improve productivity. Photo provided by DeLaval.

PHOTO 10: The first feeding of colostrum needs to be fed as soon as possible. Ideally, feed 10 to 20 percent of body weight within the first eight hours of life. Photo by Jodi Wallace.

PHOTO 11: Each of the four rooms hold 22 calves and are set up to be all-in-all-out, which helps to reduce the spread of disease and keeps calves healthier. Photo by Jenna Hurty-Person.