1. Zero-zero calf care: A team event

Published March 2019

Veterinarian Jodi Wallace coined the term “zero-zero calf care” as achieving zero treatments and zero mortality by emphasizing the importance of knowing the “why” behind each daily calf task completed by every member of the team. A wake-up call to some: Yes, this approach is possible.

Diarrhea and pneumonia are the two main causes of sickness in calves, and both are preventable diseases through proper calf care management protocols and the people who are trained to follow them.

What would be your optimal zero-zero team action plan for calf care success?

“Calves are born healthy; it is up to us to maintain their health status. It is a team effort that begins with an attitude check. Not only does the team need training on proper protocols to achieve zero-zero calf care, but training on the importance of the protocols and how every action has a reaction. Take the time to work together with your family, your team, your veterinarian and consultants to find your own ‘why’ – why should everyone care? It is a FACT that when you put your own action plan into place, you too can achieve zero-zero success:

-

Focus on feeding clean, high-quality colostrum within the first hour. The first 24 hours are key.

-

Attitude change is a must. It is important to care for calves. Why would you accept anything else but optimal health?

-

Calories, air and rest should be automatic, just like driving a car. Do not limit calories through calf milk intake; feed more clean milk. Air quality is non-negotiable, and calves need to rest on dry bedding.

- Treat calves like kids. Health is normal; sickness is not. Strive for zero-zero.”

—Dr. Jodi Wallace, Ormstown Veterinary Hospital

PHOTO: Jodi Wallace’s youngest child, Chloe, loves to help take care of the calves. Zero-zero calf care is truly a team event. Photo provided by Jodi Wallace.

Read story here: Zero-zero calf care: A team event

2. Five ways to simplify and optimize your diet

Published April 2019

Ration clutter comes in many forms, such as multiple protein and starch sources, overfeeding minerals, redundant feeds and antagonizing ingredients. Clutter can slowly creep into your rations over many years.

Daniel Scothorn with Scothorn Nutrition offered these five strategies to declutter your ration:

- Remove protein sources

- Use one source of starch

- Cut straw out

- Drop “nice-to-haves”

- Drop antagonist feeds

As you’ve implemented these strategies on farms, what cost savings could producers potentially see, and were there any consequences for milk production?

“The savings depended on the farm. I see clutter every day in dairy diets. For example, some managers were feeding two toxin binders, which were removed or reduced to one, alongside a regular toxin testing plan. On another dairy, four protein sources were reduced to two, and the manager saw savings of over 20 cents daily. In another case, a dairy was feeding barley, high-moisture corn and molasses. We helped him realize that removing one of these energy sources would save money and mixing time. Milk yield did not suffer when attention was paid to maximizing diet intake and maintaining dietary energy and protein. Often the use of fewer ingredients helps focus on the most important part of feeding, which is consistency and quality, both of which go out the door if the time is spent procuring ingredients and managing too much inventory.”

—Daniel Scothorn, Scothorn Nutrition

PHOTO: Lactating diets are often found to contain over 30 different ingredients. However, the dairy cow evolved on three sources of nourishment: grassland, water and dirt. Photo provided by Daniel Scothorn.

Read story here: Five ways to simplify and optimize your diet

3. Schuurmans family shows strength and passion as they complete Canadian Milk Tour

Published December 2018

Henk and Bettina Schuurmans set out on their Canadian Milk Tour from their Floradale, Ontario, dairy farm June 22. Traveling in an open-cab 6430 John Deere tractor, they headed west, aiming for Vancouver Island. They set out on their journey looking forward to chatting with Canadian consumers and seeing what this great country was really like.

But the tour came to a sudden standstill when a tractor-trailer collided with their John Deere tractor near Dalmeny, Saskatchewan. The Canadian farming community was shocked to hear the heartbreaking news of Bettina’s passing due to the tragic accident. Henk sustained injuries but, following a time in hospital, was released. While recovering from injuries, Henk – with the support of his children – made plans to finish the Canadian Milk Tour in memory of Bettina. He was determined to keep the conversation going about the Canadian dairy industry, family farms and quality Canadian milk – something Bettina was passionate about.

On Sept. 13, the Schuurmans set out again on the Canadian Milk Tour. This time, they travelled in a white pickup truck with a large plastic Holstein cow in the back truck bed and a small plastic calf named Minnie. Daughters Emily and Lize joined Henk for the first leg of the trip. Emily was only able to get a short time off from her job; Lize was able to complete the entire Canadian Milk tour with her dad.

“This trip was needed. It was part of the healing process for our family,” Henk says. “And I wanted to revisit all of the farmers we got to know on our first trip and to thank them for their support after the tragic accident.”

It took four weeks to complete the West Coast tour. They took two days’ rest back at the farm in Floradale, then Henk and Lize headed to eastern Canada. They completed the East Coast portion in a mere two weeks in late October.

How have your promotional efforts continued? And what advice do you have for other dairy producers?

“I found a mini Minnie calf to take with me to Holland, Germany and America. It helped me engage with my followers on social media to show them that I’m still continuing my efforts. I wanted to make the point that I’m not just finished with the Canadian Milk Tour and that’s it.

“Travelling outside of Canada, it’s easy to see how each country has its own problems with farming; especially in Europe right now, as they want to cut the amount of nitrates in half. It would mean the livestock farms would have to cut their herds in half. The Dutch farms are really standing up as a united group with rallies at Parliament. When I see that, I feel such a unity between the farmers. They stand up together and, in a friendly way, they demonstrate. There is a unity there we don’t have in Canada for some reason.

“Those in Quebec seem to have that a little more because they do something similar. I know they live closer to Ottawa, but that’s not an excuse; we all have our own local government that we could impart with our situation. We don’t have to travel far to get our point across. We can stay very close to home to let our politicians know what’s going on, what hurts our industry and what our concerns are.

“I’ve been on a Dairy Farmers of Ontario committee for six years, and I find it hard to get people engaged in our industry. There’s a lot of people who have comments or complaints, but yet I don’t ever see them at the local or annual meetings. That’s really frustrating if you’re on committees, and you hear these complaints in the field, and yet you don’t see these people in our meetings. That’s where it all should start; they should stand up and tell their frustration or their ideas. Dairy Farmers of Ontario is doing a good job. They try to represent all of the farmers, but the farmers have to show their engagement with the industry too.

“Boards of directors and committees are there for a reason. They need input from the grassroots, from the farmers in their local areas. That’s where you should start; engage with them. You don’t have to spend a lot of time, it’s just one evening here or there to at least stand up and discuss things with committees. They often have roundtable discussions so you’re not being put on the spot, or you can write a letter or send an email.”

—Henk Schuurmans, Milky Wave Inc.

PHOTO: When the tour resumed in September, the Schuurmanses traveled by pickup with a cow in the truck bed and more positive messages for the industry visible to all they met. Photo by Sharon Grose.

Read story here: Schuurmans family shows strenfth and passion as they complete Canadian Milk Tour

4. Fairlife invests in the Canadian dairy industry

Published April 2019

During the 2019 South Western Ontario Dairy Symposium, the director of fairlife for the Minute Maid Company Inc., Coca-Cola Limited (CCL), Carolyn Novick, presented the fairlife story to dairy producers. Joined by fairlife vice president of communications Anders Porter and Jacqueline McCloskey, daughter of Mike and Sue McCloskey from Fair Oaks Farm, the founders of the brand, the group talked about the history of fairlife milk, the brand and their plans to invest in the Canadian dairy industry.

Scheduled to complete construction of their $85 million processing plant in Peterborough, Ontario, spring 2020, they have been working closely with Dairy Farmers of Ontario (DFO) to learn more about Canadian dairy and how they can work together to source milk from local Canadian dairy producers. They look forward to the positive impacts that will filter down to dairy producers and retailers as soon as the plant opens, using only 100% Canadian milk.

What updates do you have to share as you approach completion of the plant?

“We are making great progress on the new plant in Peterborough and are on track to begin operations in spring 2020. So far, we have completed most of the ‘outside’ work – exterior walls, roof, etc., and we are now working on the ‘inside’ elements.

“Hiring has started for the key local management and operations roles. A number of key plant leadership roles have already been filled, and we are currently recruiting plant technical staff in maintenance and quality control roles. (Visit Coca-Cola Canada Careers to see what roles are currently available.)

“We are very excited to get the new plant up and running using 100% Canadian milk. There are still a few misconceptions that the new plant will bottle U.S. milk, or that we will continue to import fairlife once the Canadian plant is up and running, but neither of those are true. Once the plant is in operation and our Canadian products start entering the market, we will no longer be importing fairlife. We are continuously working with DFO on the quality standards for the new plant and will be able to pull from the general milk supply due to the excellent quality of Canadian milk.

“We can also say that Canadians are really enjoying fairlife milk. After our first year in Canada, we are seeing great results. In the regions where fairlife is available (Ontario and western Canada), fairlife is driving approximately one-third of the growth in value-added dairy. On top of that, approximately 40% of fairlife sales came from outside of the dairy category. These results demonstrate that fairlife is helping to bring Canadians back into dairy and helping grow the dairy category, which is good for dairy producers. One reason is because fairlife has a very attractive target market, appealing to millennials in five-plus- member households, as well as the 55 to 64 demographic and households with kids and teens. We are seeing an excellent repeat rate in comparison to other recent Canadian dairy innovations, meaning consumers are trying the product and coming back to purchase, which is great news for the Canadian dairy industry.”

—Carolyn Novick, director of fairlife, The Minute Maid Company Inc., Coca-Cola Limited (CCL)

PHOTO 1: Jacqueline McCloskey, daughter of fairlife’s founders, addresses Canadian dairy producers at the South Western Dairy Symposium, which took place Feb. 21 in Woodstock, Ontario. Photo by Lora Bender.

PHOTO 2: The construction of the fairlife plant in Peterborough, Ontario, is well underway to begin production in spring 2020 using 100% Canadian milk. Photo provided by fairlife.

Read story here: Fairlife invests in the Canadian dairy industry

5. Incomplete milking challenges early lactation health woes

Published April 2019

An Agriculture and Agri-Food Canada (AAFC) researcher from the Sherbrooke Research and Development Centre, Dr. Pierre Lacasse, has dedicated much of his time to improving health in early lactation dairy cows. His discovery of an “incomplete milking” during the first five days of lactation has resulted in much more positive health outcomes for the cow. This method has provided the cow’s metabolism time to adapt, and the result is a sharp drop in metabolic and immune disruptions.

Lacasse’s research team recommends harvesting 10 kilograms of milk per day for the first three days of lactation and then increasing to 12 and 14 kilograms per day for days four and five.

What research are you working on now?

“Currently, we are working on the mechanisms by which non-esterified fatty acids affect the functions of immune cells. We hope that it will help us to find some ways to preserve immune cell integrity during periods of negative energy balance. Also, we hope to conduct in the future, another incomplete milking trial that would answer some of the concerns some producers have expressed about the welfare of the cows.”

—Dr. Pierre Lacasse, Agriculture and Agri-Food Canada Sherbrooke Research and Development Centre

Read story here: Incomplete milking challenges early lactation health woes

6. Tom Robinson finds his fit with farming and family

Published April 2019

In 2016, Tom Robinson and his wife, Leslie, purchased his parents’ dairy farm in Prince Edward Island. The herd consists of 85 milking cows, all registered Holsteins, along with about 70 head of dry cows and youngstock. His heifers are all home-bred. When the market was strong for embryos, Robinson flushed several cows each month, with embryos sold to Nova Scotia, the U.S., Australia, New Zealand, Finland, Germany, Argentina and Brazil. Presently, with less demand, he flushes just a few times a year. Robinson’s herd averages 35 litres per cow with an average butterfat of 4.6%.

Robinson is making some changes to the operation. He found hiring custom operators for harvesting did not optimize his harvest, so he thought he could have better production by doing the harvesting himself. After doing some research and crunching numbers, he and his dad, as well as his two uncles, took a trip to France, where he purchased a used John Deere self-propelled forage harvester. Now he also does a bit of custom work, which is helping to pay for the machine.

Future plans include more bunker silos and perhaps a heifer facility, although Robinson indicates that if quota becomes more available, he might build a bigger dairy barn and use the present one for heifers.

Robinson is past president of the Prince Edward Island Holstein branch and was involved in planning and hosting the 2019 National Holstein Convention in Charlottetown, Prince Edward Island.

What did you gain by devoting your time to planning the National Holstein Convention?

“My biggest takeaway from helping to plan the 2019 National Holstein Convention was an awareness and appreciation of how much goes into putting together such an event and all of the things that pop up and need to be sorted out along the way. It’s really important to pay attention to past conventions during the planning process and learn from what they’ve done, what worked and what didn’t. I’m used to working as part of a team and have worked with many of the planning committee members in other capacities, but the scale of this project was bigger and allowed for the opportunity to connect with others in the dairy industry in a way that I wouldn’t normally as just an attendee at the convention.”

—Tom Robinson, Blue Diamond Holsteins

PHOTO: Tom and Leslie Robinson are raising their three young daughters on the farm. They are, left to right, Miranda, Lanae and Rosalie. Photo by Cherished Memories Photography.

Read story here: Tom Robinson finds his fit with farming and family

7. VanderKoois finish up renovations prior to farm tour

Published January 2019

Ashley and Richard VanderKooi both grew up in the Fraser Valley area of British Columbia on dairy farms. They moved to Saskatchewan in 2006 to establish a farm on their own. Land was less expensive, and there was more of it available. Quota was also cheaper, and they grew their herd to 260 cows milking at that location.

After eight-and-a-half years, they were ready to move back to British Columbia to be closer to both sets of parents as well as siblings. They settled near Chilliwack in the eastern Fraser Valley. They downsized the herd to 80 cows, as they were initially only able to get 70 kilograms of quota (half of what the seller had). Within four years, they more than doubled their quota and were back up to 140 cows. Their growth has leveled off now, and they have no immediate expansion plans other than to grow within their own herd.

The farm they bought was in need of renovation. They started with the parlour, changing a double-nine herringbone to a double-nine parabone, with space to expand to a double-12 if needed. It will be equipped with an adjustable headgate to accommodate the farm’s mixed herd of Holstein, Brown Swiss and Jersey cows.

Renovation plans include freestalls along with box stalls for calving and a flush system for alley cleaning. There will be three sections of stalls, sized for Jerseys, 2-year-olds and mature Holstein and Brown Swiss cows. The barn will feature rubber on the floors and feed alleys, and will be bedded with sand. There will be a sand recovery system and a manure separator which removes fibre, giving a cleaner flush at the end. Sort gates, a footbath and hoof care area are included in the plans.

How is the new barn working for you?

“The new barn is working like we expected; cows are happy and have more room. We are really happy with our sand lane, as we are able to reclaim 90% to 95% of clean, good-quality sand. We haven’t brought in new sand in since March 2019. I am glad to have a holding area that loads from the back with a proper crowd gate and a proper-sized sort pen with lock-ups. The only thing we would change at this point is to crown the stall alleys to clean up along curbs better.”

—Ashley VanderKooi, Lone Prairie Dairy

PHOTO: A new barn offers a large bedded-pack space. Courtesy photo.

Read story here: VanderKoois finish up renovations prior to farm tour

8. Drying hay in a new way

Published February 2019

Lars and Ingrid Steunebrink from Kirkton, Ontario, found a new way to dry hay. Determined to gain on-farm efficiencies and feed top-quality nutritious hay to their (by now) 1,000-head herd of dairy goats, the couple looked at different technologies and installed a hay-drying system from Austria.

Housed in a building with a backup generator, the system includes a dehumidifier, an 80-kilowatt fan, two hay boxes sized 325 and 280 square meters (3,498 and 3,014 square feet) and a hay crane for collecting and distributing hay among the boxes. On a typical day, 60 to 100 acres of hay are harvested, at 30% to 35% moisture, at a cost for drying of 0.5 to 1 cent per pound of dry hay. Two boxes of dried hay per year are required to feed their herd, so the extra will be sold in small or square bales to wholesalers and local farmers. The Steunebrinks expect the system to last over 20 years with hopes to grow their operation in the next 10.

Now that two seasons have passed using the hay-drying system, are you happy with the results and feedback you’ve received?

“We are happy with our drying system, and it works well. We get high-digestible results – the hay is excellent. This year, our first cut had a relative forage quality (RFQ) of 228, second was RFQ 199 to 203, and the third was RFQ 218. On top of making small squares in bundles, we are now working on getting a large 3X4 baler modified to bale the hay out of stock and still be able to bale straw in the field.

“We feed less pellets/grain to our goats, which makes happy, healthy goats. Besides our goats, there are horses, calves, cows and pets enjoying our hay, and they love it because farmers keep coming back for more.

“There is lots of interest in this system here in Canada; people are searching for a way to be less dependent on the weather when making hay. Because of being able to cut early, we are able to make more pounds of dry matter per acre per year and also of a higher quality.”

—Lars Steunebrink, dairy goat producers, Kirkton, Ontario

PHOTO: The drying system includes a hay crane to distribute hay among the boxes. Courtesy photo.

Read the story: Drying hay in a new way

9. How to optimize conception rates of sexed semen

Published March 2019

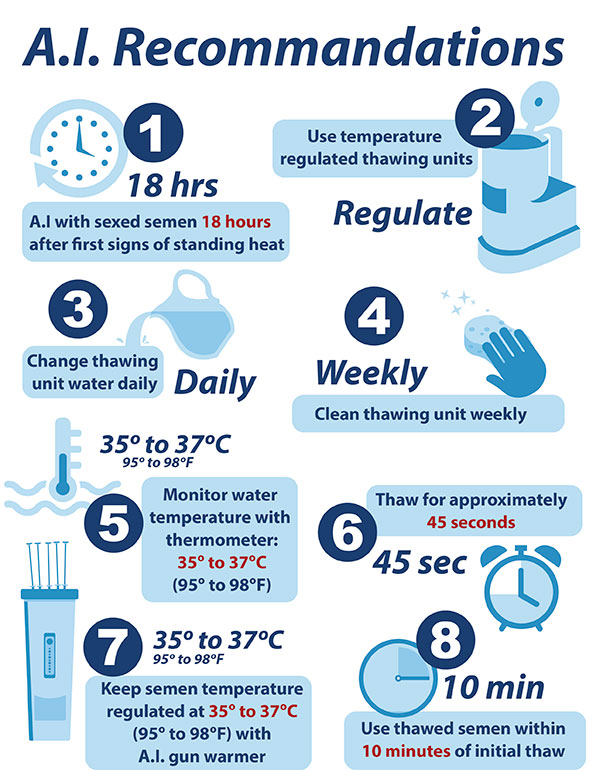

With advancements in sexed semen, both affordability and availability of the best bulls have improved, and breeders are now obtaining results similar to those observed with conventional semen. As with any modern technology, there are some parameters to consider maximizing results. One key to on-farm conception rate success is delayed service time. Sexed semen performs better when used 18 hours after estrus (peak heat), compared to about 12 hours for conventional semen. Success is also dependent upon following the same thawing and storage guidelines as used for traditional A.I.

What trends do you see regarding the use of sexed semen in Canadian dairy herds?

“In the past years, in an attempt to achieve progress and profitability in a context with tighter margins, the Canadian dairy producer has adapted by using more effective strategies when it comes to replacements in the herd.

“Maximizing genetic progress and capturing the best financial outcome has been possible with sexed semen on the chosen best animals. Securing that genetics ensured the Canadian producers a future with more certainty just when risk management has to definitely be more and more part of their future. We have evolved from using sexed semen on heifers only for calving ease reasons to a real strategy by using the improved technology of high-fertility sexed semen on superior females in the herd, be it a heifer or a milking cow in first lactation, second lactation or more.

“By doing so, Canadian dairy herds have certainly seen a rise in the usage of sexed semen on the farm, in parallel with more ‘beef-on-dairy’ semen bred in dairy cows. This comes with a new source of income not yet grabbed in the past but now a reality: income from crossbred calves leaving dairies. That number of crossbred calves has more than tripled between 2015 and 2019.

“That strategy pays off on both ends: more from the top for renewal of the herd with more certainty in future dairy performance, as well as more from the rest of the herd not used for replacement. There is a 96% difference in price on average for 2018 between a crossbred calf and a pure Holstein calf at the auction, so this just made money sense for producers. Now sexed male beef semen on this group is also becoming a reality in more Canadian dairy herds, driving more dollars back to the farm versus female crossbred calves, up to three times more money for male crossbred beef calves than pure Holsteins.

“In fact, it is the availability of sexed semen achieving comparable conception rates to conventional semen that has made this a possibility on dairy farms. Such a strategy allowed producers in the past year to foresee a continued trend and increase in the use of sexed dairy semen, coupled with beef semen in Canadian dairy herds all across the country.

“A.I. companies are seeing a higher demand for sexed semen; the worldwide leader in sex-sorted semen production has witnessed a 26% increase in sorting demand in the last 12 months. On the other end, beef-on-dairy semen usage has more than doubled in 48 months nationwide. What was called a trend is now a real strategy in place for a progressive dairy’s business plans.

“High fertility of sexed semen has changed this strategy for the better in Canadian dairies.”

—Jean-François Thouny, STgenetics Canada

Read story here: How to optimize conception rates of sexed semen

10. Canadian brewers distill vodka from milk permeate

Published February 2019

There are few who make spirits out of milk, and the Dairy Distillery in Almonte, Ontario, is the only one in the world doing it with milk permeate.

Milk permeate is a byproduct of ultrafiltered milk production. After finding the right yeast for fermenting lactose, the distillery is able to convert this leftover milk product into consumable vodka.

What new updates or changes have been made in the past year to the distillery?

“We have made lots of progress in the last year. We are now selling province-wide in Ontario, Alberta and Nova Scotia. We’ve increased the distillery’s capacity fivefold and are taking in 15,000 litres of milk permeate a week. To top it off, we have sold over 25,000 bottles of Vodkow to date. We’re planning to enter the U.S. market next year and are looking for partners interested in working with us to make Vodkow with American milk permeate.”

—Omid McDonald, Dairy Distillery

PHOTO: Vodkow is produced out of the Dairy Distillery in Almonte, Ontario. Photo provided by Omid McDonald.

Read story here: Canadian brewers distill vodka from milk permeate

11. Semen tank management: A dozen do’s and a few don’ts

Published December 2018

Semen tanks require routine checks and maintenance to ensure they are keeping frozen semen as fresh as the day it was processed. Be sure to have tanks regularly filled with liquid nitrogen, and place a wooden pallet or rigid foam underneath to increase stability and prevent direct contact with the floor surface. Store in a location outside of the milkhouse, and only move the tank when absolutely necessary. If transportation is required, tanks must be strapped securely into the bed of a pickup. Regulations on the transport of dangerous goods require tanks to not be in the passenger compartment of a vehicle. Watch for rapid frost buildup around the outside of the neck tube, which indicates vacuum loss and imminent tank failure.

In which area of semen tank management do you most commonly find error, and how can that impact semen viability?

“I often find general lack of attention regarding the level of the canister in relation to the frost line in the neck tube. Oftentimes, the canister is held well above the frost line while searching for a cane of semen, exposing multiple straws to temperatures that will cause partial thawing. When the canister is lowered back into the tank, re-freezing occurs, causing irreparable damage to sperm cells. Viability of the semen is severely compromised. I often suggest using a clip to eliminate this problem.

“Many will do a good job keeping the canister below the frost line but forget to keep the individual cane below the top of the neck tube while retrieving a semen straw with tweezers. Again, this exposes multiple straws to temperatures that will thaw semen. Remember, it’s not the semen straw we are thawing in the water bath we need to be concerned about, but all the expensive inventory in the tank that we are subjecting to reduced viability.”

—Bruce Poulin, EastGen

PHOTO: Keep semen tanks off concrete and switch tanks once frost buildup occurs. Courtesy photo.

Read story here: Semen tank management: A dozen do’s and a few don’ts

12. Celmar Dairy saves labour with automated forage filling and feeding

Published August 2019

When Marcel and Annika Steen set out to farm on their own in 2006, they looked to automation as a way to farm with minimal extra manpower. They utilize automated milking and feeding systems in addition to a silo-filling dump bay at Celmar Dairy in Norwich, Ontario.

The concrete in-ground pit with conveying system enables them to quickly drop a load of silage and head back to the field while the equipment blows the crop into the upright silo.

The silos work well with the farm’s automated feeding system. The feed kitchen is set up with conveyors from the silos to overhead hoppers that automatically refill as needed. There are also mineral bins and shredder tables for bales.

The system automatically fills, mixes and delivers 25 loads of feed per day broken into six different rations. The Steens keep their animals from 2-month-old heifers through milking and dry in the main barn, which makes it easier for feed delivery.

They use three milking robots for their herd of 170 cows. These were recently replaced with the latest model offered by the company. The newer milking robots are quieter and are saving the Steens 20% on their hydro bill.

What are the next three changes you’d like to make on your farm?

“The next three changes for our farm include:

1. Continue renovating more freestalls to deep bedding. We currently have dry cows and both mature milking groups done but still need to do first-lactation heifers. We would like to start changing the heifers as the existing mats need to be replaced. We feel the comfort of deep bedding can’t be matched.

2. Calf barn ventilation. We are in process to overhaul and add ventilation in our calf barn. We’ve been running a negative pressure-type system but have not been completely happy with it. We’re looking into adding forced fresh air ducts and other methods to improve the ventilation here.

3. NIR technology to the feed room. We would like all ingredients to be ran across an NIR system before entering the Vector feeding system to get a complete analysis of the feed, which will allow us to dial-in day-to-day feeding rates.”

—Marcel and Annika Steen, Celmar Dairy

PHOTO: The Steens built a dump bay for unloading silage. A 200-horsepower, electric-driven blower puts the silage in the silo. Photo by Karen Lee.

Read story here: Celmar Dairy saves labour with automated forage filling and feeding

13. Compass Dairy Farms Ltd. enhances existing facility with six-row barn and rotary parlour

Published online November 2018

A new 50-stall external rotary parlour at Compass Dairy Farms Ltd. in Mount Elgin, Ontario, allows the De Beer family to milk 210 to 220 cows per hour with three people. It reduced the milking time for this 480-cow farm from six-and-a-half hours to two-and-a-half hours per shift.

There is a sorting area as cows exit the parlour for breeding and treatments to be done each morning. A new sand-bedded, six-row freestall barn features insulated roof panels, capped I-beams, automated manure scrapers, sand bedding and perimeter feeding.

Cows wear rumination and activity monitors. Using parent average, they breed the top 60% of cows to conventional semen and the bottom 40% to beef, and raise the British Blue crosses themselves. The top 75% of heifers are bred to sexed semen and bottom 25% to conventional semen.

PHOTO: The installation of a 50-stall rotary parlour helped the De Beers cut down on milking time, reduced time spent in the holding area and improved the consistency of the milking routine. Photo by Karen Lee.

Read story here: Compass Dairy Farms Ltd. enhances existing facility with six-row barn and rotary parlour

14. New recommendations for calf feeding using automated feeders

14. New recommendations for calf feeding using automated feeders

Published November 2018

Traditional feeding programs limit calves to a few large meals a day. This can be problematic when calves are still learning how to use an autofeeder. Instead, farms should consider feeding calves using the economics feeding curve or the metabolic feeding curve, which help alleviate this issue and set calves up for success.

In the article, you mentioned that when using the metabolic feeding curve, the milk phase can be shortened by two weeks. (Calves are 8 weeks old at weaning.) What are some key indicators calves are prepared for an earlier weaning?

“The right moment to wean a calf is when the calf digests a significant amount of dry feed (e.g., 1 kilogram of starter per day for at least three to four days). But the digestive system of the calf needs approximately 10 to 14 days to adapt to changes in the diet. That means it is an absolute no-go just to skip a milk feed and one week later take away the milk completely. We should better focus on the weaning procedure than the ‘signs’ of readiness for weaning. Automatic calf feeders can wean the calves gradually over a period of two to six weeks. The calves will react with an increased starter consumption if the milk is removed. The recommended milk curve would be a start phase with approximately 8 to 10 litres per day for four weeks, then gradually wean the calves over a period of four to six weeks. At this moment, the starter intake will not yet be significant. With this procedure, the last two weeks (week 9 and 10 in the life of the calf) would not matter so much, since 80% of the calf’s consumption is dry feed anyhow. That is where the milk period could be shortened.”

—Holger Kruse, Holm & Laue

PHOTO: Calves in feed barn. Photo courtesy of Holm & Laue.

Read story here: New recommendations for calf feeding using automated feeders

15. Gezinus Martens finds fulfillment in serving the industry

Published March 2019

Gezinus Martens is passionate about training young people and says he feels a responsibility for the success of the next generation. One of the best ways to help them succeed is by education – not just hands-on, in-the-field training but by teaching management skills. He says colleges should reflect the industry, teaching those skills so the students they turn out become the managers of the future, not just stable help.

Martens and his wife, Bea, emigrated from the Netherlands in 1998 to provide better opportunities for their young family – two sons and a daughter. They purchased a small farm in the Calmar, Alberta, area, building a new facility for 80 cows. The business quickly grew. In 2005, he built a new barn, doubling his capacity. In 2014, he added two automated milking systems and is now milking almost 130 cows. Martens is in process of building another new barn, which will allow him to increase the milking herd to 300 cows. This is a guided-flow freestall facility, with four more robots and an in-line milk analyzing system.

To Martens, success of the entire industry trumps individual success. He is part of Lakeland College’s advisory committee, has been a board member of Alberta Milk for six years, is involved with Alberta Dairy Congress and the Holstein show in early June at Leduc. He is involved with milk transportation and research in the dairy industry. This year, he was chairman of the Western Canadian Dairy Seminar (WCDS).

What makes the Western Canadian Dairy Seminar worthwhile for dairy producers?

“The Western Canadian Dairy Seminar will have its annual conference for the 38th time March 10-13, 2020, in Red Deer, Alberta. It is a great place for people from the dairy industry to gather. More than 850 people attend the seminar each year. Not only dairy producers (41%) but also industry service providers (41%) as well as veterinarians, and university and government employees (18%). Perhaps its formula for success is in the seminar’s mix of knowledge sharing, networking and adoption to new ideas. Some changes made the last couple [of] years is implementing a producer panel and the student research presentation competition, which showcases some of the up-and-coming young researchers. Many of those projects have been partially funded by the dairy industry itself.

“The producer panel is rated as one of the most-attended talks because it is unbiased and straight talk from farmer to farmer. The seminar’s connection between the industry and universities gives producers the chance to see the results of new research and also share their own ideas or challenges with the academic community, helping to keep research relevant to the industry’s needs. I try to attend as often as I can so I can stay up-to-date with the latest industry research and trends as well. It is definitely time well spent. Go to www.wcds.ca for more information about the event.”

—Gezinus Martens, Triple M Dairies Inc. ![]()

PHOTO: Gezinus Martens (right) is working on transitioning the 130-cow and 600-acre farm to his sons, Ronny (left) and Johan (center). Photo provided by Gezinus Martens.

Read story here: Gezinus Martens finds fulfillment in serving the industry