“Water seems to be the last frontier for dairy,” says Simon Stelfox, Water 4 Dairy general manager. To conquer this uncharted territory, Stelfox left work as a strategist for large publicly traded companies to found Water 4 Dairy, which is introducing a revolutionary water treatment system to the dairy industry.

The WD Series is an ozone-based water treatment system to optimize water quality and streamline the productivity of dairy animals.

“We treat a wide range of water issues well,” Stelfox says, noting the system is designed for anyone looking for improved water quality and stability.

It is chemical-free and low-maintenance with filters that automatically backwash and an onboard self-diagnostics system containing an LCD screen that tells the operator if everything is OK or if something needs to be fixed.

Henrik Helmig likes the simplicity of it. “We don’t have to do hardly any maintenance,” he says.

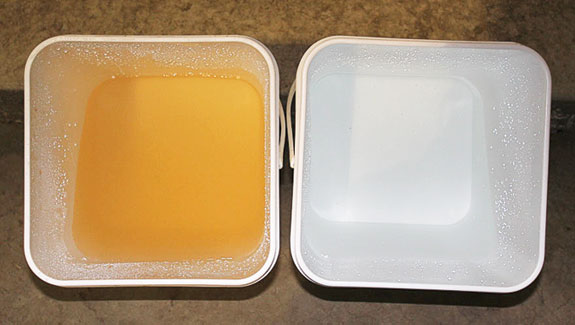

Helmig has been using this system on his 190-cow dairy in Olds, Alberta, for the last three months. He says it has made a big difference with the iron in his water supply and has noticed the water and water troughs are cleaner.

“We didn’t expect the water to be this clean,” he says. “When you compare the (before and after storage) tanks, there’s a huge difference.”

To clean the water, an injector introduces ozone gas to dirty water as it is drawn into the system.

A mass transfer nozzle further churns the water, creating microbubbles that result in a greater surface area of ozone gas, allowing for maximum disinfection of the water.

The bubbly water is mixed in a contact tank for four minutes before exiting through multi-stage filtration and ending with a carbon filter.

The filters not only remove the ozone gas but are also customized for each dairy to remove any particulates that can cause bad odours and taste.

“Our system is on-flow, on-demand, treating up to 30 gallons of water per minute,” Stelfox says of the WD30SX model. It kicks on when someone or something turns the water on and turns off one minute after the water is shut off.

The one-minute delay helps prevent on-and-off usage if someone is using a faucet often and it helps to supersaturate the water with ozone.

When turned on, the WD30SX model will recirculate water internally at a rate of 30 gallons per minute. If the farm is only drawing water at 20 gallons per minute, the remaining 10 gallons per minute of clean water is returned to the start of the process and blended with dirty water from the farm’s raw water supply to keep a continuous flow.

“We’re overtreating the water,” Stelfox says of what happens when the farm is not using 30 gallons of water per minute 100 percent of the time.

That is okay with Kevin Slomp of Monarch, Alberta, who has been using this for a month and is impressed by how clean the water is.

“We’ve always struggled with water. It was dirty, smelly and had E. coli spikes,” Slomp says. Now the E. coli has dropped significant amounts, basically to nothing, he explains, and the water is “crystal clean.”

His 220-cow herd has reacted well to the change. “The cows drink a lot more; they eat a lot more and dry matter intakes have gone up. We’ve seen changes already in our milk tank,” he says.

Before Stelfox installs a treatment system on a dairy he performs an extensive water test that looks at factors even beyond what Canadian Quality Milk requires. He looks for opportunities to improve water on the dairy and then makes a recommendation to the dairyman.

This information helps to develop the system, determining whether storage tanks are required, what type of filtration is necessary and what dosage of ozone is appropriate.

The company also installs a flow meter to data log water usage. The system is then designed to accommodate the farm’s peak usage rate.

“We’re helping them understand their water usage and that the capacity of the system is appropriate to fit their needs,” Stelfox says, noting it is designed slightly greater than the farm’s current usage because on-farm research has shown that cows end up drinking even more water once the system is in place.

There are additional models available to meet the varying capacities of farms. The WD15SX treats 15 gallons of water per minute, while the WD60SX treats 60 gallons per minute.

The size of system required depends on how the dairy is using its water. “Every farm is different from a water usage perspective,” he says.

Pricewise, this system is not a small investment – with the 30-gallon-per-minute system starting at $43,000 installed. Water 4 Dairy does offer lease-to-own or financing options where payments are comparable to what some farms spend on chemical treatment systems per month.

Picture Butte, Alberta, dairyman Nico Van Der Smit estimates he’ll have his system paid back in two to three years if it continues to operate as it has the last five weeks since he installed it.

“So far it’s running really good. There’s crystal-clear water and we don’t have to deal with hydrogen peroxide,” Van Der Smit says. The last system he used involved hydrogen peroxide, which he found to be quite expensive each month and not the safest to handle.

“We have tried all kinds of different water systems,” he notes, mentioning he purchased this one after hearing other farms in the area were using it.

The very next day he saw a difference in the water on his 120-cow dairy. Now the water troughs stay clean and don’t have algae growth.

Stelfox says he’d like to help others in the dairy industry that have tried to fix their water problems and failed. “There is an unfortunate negative perception of water treatment in the dairy industry and I’d like to correct that,” he says. PD

Click here for more information or to locate a dealer.

PHOTOS

TOP: This Water 4 Dairy WD30SX system treats 30 gallons of water per minute with ozone gas at Van Der Smit Farms in Picture Butte, Alberta.

BOTTOM: Dirty water (left) becomes crystal clear (right) after cycling through a new water treatment system. Photos courtesy of Water 4 Dairy.

YOUR RESULTS

Would you benefit from this type of water cleaner?

The following checklist can be used to determine if this new technology might be a fit for your operation.

1. Do you use water on your dairy?

2. Are there particulates in your water?

3. Does it have a bad odour?

4. Does the water have an off taste?

5. Do you need to reduce E. coli levels in your water supply?

6. Would you like for your water to be cleaner?

7. Do you want to avoid treating water with chemical solutions?

8. Are you interested in a low-maintenance water treatment system?

9. Would you want to increase the water intake of your dairy herd?

If you answered yes to seven or more of these questions, this technology may be one for you to consider.