Manure is a valuable source of nutrients and soil-building organic matter. It is always important to manage manure nutrients to maximize availability for crops and minimize environmental losses, but that is especially true this spring as fertilizer prices have skyrocketed. Several strategies and practices can be used on the farm to realize the full value of those manure assets.

Sampling manure for analyses

The first step to manage manure nutrients effectively is to have it analyzed for nutrient content. Manure is an inherently variable nutrient source, changing composition with animal type, weather, and rain additions to open storages. Annual manure analyses will allow you to build three-year running averages for the farm, which is more reliable than using book values. See Agronomy Factsheet #38 for guidance on proper sampling procedures and analysis.

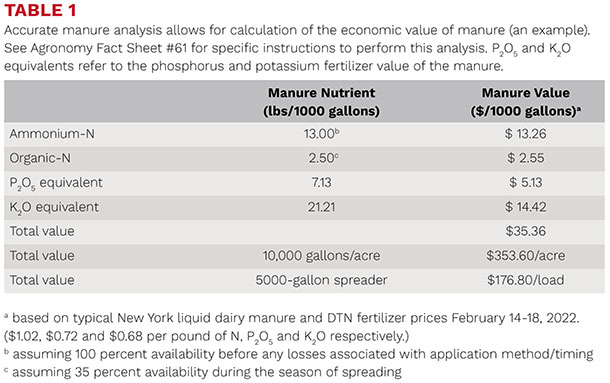

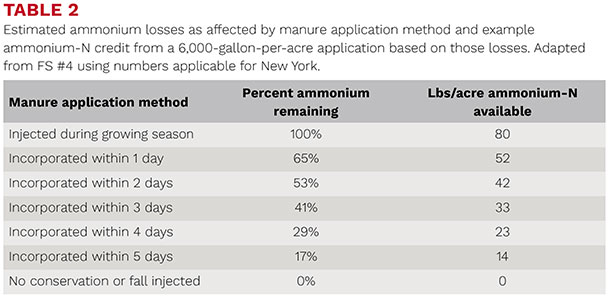

With accurate manure analysis and knowledge about fertilizer prices, we can quantify the economic value of manure. The calculation shown in Table 1 is an example. Keep in mind that the value of ammonium-N in manure can be impacted by how and when manure is applied (Table 2).

Manure spreader calibration

Proper manure spreader calibration takes the guesswork out of achieving target application rates. If flow meters are being used, they too should be calibrated. Agronomy Fact Sheet #18 was recently updated and includes several methods for calibrating spreaders and flow meters. Manure spreader calibration is a weak link in many operations. It is easy to overestimate what is being spread if relying only on spreader capacity ratings. If you are overestimating application rates, even by a small percentage, it can add up significantly over the course of a cropping season, possibly shorting the crop. If you’ve taken the time to soil sample, manure sample, and follow a nutrient management plan – calibrating your spreader is the final step for accurate planning, application and record-keeping.

Nutrient credits from manure

Crediting nutrients from manure applications can get complicated. The first thing to remember is that manure nutrients applied last fall count towards this year’s crop. For example, if you applied manure containing 50 lbs P2O5 in November, all 50 lbs will count towards this year’s crop nutrient budget. Similarly, P and K in manure applied this spring will count as 100 percent available.

Nitrogen is a much more complicated equation. As livestock manure is made up of both urine and feces, there are two forms of nitrogen to account for (Figure 1).

Ammonium-N (sometime reported on manure analyses as inorganic N or ammonia-N) is the more plant-available form, behaving like urea fertilizer. Organic N is the form that mineralizes more slowly. Determining N credits from manure applications involves knowing how much of each form was applied.

In New York, we assume 35 percent availability of organic N in the year of application and 12 and 5 percent two and three years after application, respectively (see FS#4 for organic N credits). For proper crediting of ammonium-N, timing of incorporation has a big effect on how much will be available to the crop. Table 2 shows the ammonium-N credits used in New York. It illustrates how quickly ammonium N losses can occur following application, similar to what is expected to happen with fertilizer N. Consult your state’s guidelines for appropriate credits for organic and ammonium N in manure.

If you have adequate storage, spreading during the growing season is the best way to maximize nutrient value of manure and avoid environmental losses. If you spread last fall or winter, it is highly likely that all that readily available inorganic N is gone before the spring-planted crop can get to it. By far, the most efficient and effective method to retain manure nutrients is direct injection or immediate incorporation close to planting or into a growing crop. Getting the manure in direct contact with the soil right before (or during) crop growth will provide the biggest bang for your buck. There are several ways to accomplish this depending on your situation and equipment, as discussed below.

To calculate total N availability from manure for this year’s crop, you should account for all the organic N and ammonium-N credits. See Figure 1 and the calculation below for how that is done in New York. For a more complete discussion of nitrogen credits from manure, see Fact Sheet #4.

This year’s ammonium N (x availability factor) + this year’s organic N (35%) + last year’s organic N (12%) + two years ago organic N (5%) = total N available for this year’s crop from manure.

Example

A field receiving a 6,000-gallon-per-acre manure application for three years in a row would calculate nitrogen credits as follows (using manure nutrient values as shown in Table 1):

Manure incorporated within 24 hours of spreading:

13 lbs ammonium-N (0.65) + 7.3 lbs organic (0.35) + 7.3 lbs organic (0.12) + 7.3 lbs organic (0.05) = 8.5+2.6+0.9+0.4 = 12.4 lbs available N/1000 gallons x 6000 gallons = 74 lbs available N

Manure surface applied without incorporation:

13 lbs ammonium-N (0) + 7.3 lbs organic (0.35) + 7.3 lbs organic (0.12) + 7.3 lbs organic (0.05) = 0+2.6+0.9+0.4 = 4 lbs available N/1000 gallons x 6000 gallons = 24 lbs available N

Application method

Split Applications

Splitting up manure applications on hay fields is a tried-and-true way of maximizing nutrient use by perennial crops. Multiple smaller applications are more expensive than a single pass but in this economy, it can pencil out. In addition to reducing the need for purchased fertilizers, utilizing manure between hay harvests during the summer can help relieve manure storage capacity limitations, optimize yields, and increase forage quality by keeping protein levels in forages high. There are challenges that need to be considered in this scenario. These include the potential spread of pathogens, notably Johne’s disease, and potential feed hygiene issues if manure residue is picked up in subsequent cuttings. This can be managed by the type and rate of manure application along with proper setup of harvest equipment to minimize the pickup of surface debris with the forage.

In corn and other annual crops, spreading in the spring before planting isn’t the only option. Recent studies from Ohio State University Extension and elsewhere show that you can top-dress corn and cereal grains through emergence and up through the early vegetative stages without damaging the plants, using careful planning. Manure applied as a sidedress in corn showed promise for increased yields and the elimination of nitrogen fertilizers in New York too (Godwin et al., 2018), but such equipment is currently not commercially available.

Incorporation & Injection

Getting manure in contact with soil as soon as possible is key to conserving nutrients. Choosing the right approach will depend on your crop rotation, equipment, and tillage regime. Incorporation through tillage is simple and straightforward in theory. The downside is, in practice it can be difficult to spread manure and incorporate it immediately if the incorporation equipment is not integrated with the manure spreader (i.e., if you need a separate tillage pass). In addition, spring tillage can be tricky, often causing significant compaction and detrimental soil conditions if done when soils are still wet. But with good preparation, adequate labor and tractors available, it can be accomplished by having the tillage tractor follow immediately behind the spreader.

Direct injection is the most efficient method – accomplishing the best nutrient retention and most efficiency for labor, fuel and equipment use. Paired with a drag-hose system, this is a win-win. This combination reduces compaction, increases efficiency, and even helps with neighbor relations (reducing truck traffic and odors associated with spreading). Disc and shank injectors have many different options for setups that can be adjusted for depth, disturbance, and spreading width. They can be mounted directly to tank spreaders or used with a drag hose. Manure injection matches well with reduced and no-till cropping systems. Research looking at direct seeding of corn after manure injection on farms that have improved soil health practices shows that yields can be maintained while eliminating all other field passes between manure application and planting (Battaglia et al., 2021). An intermediate approach is to incorporate manure through shallow tillage but retain surface residue in reduced tillage systems. Previous work in New York using an aerator toolbar in the spring after manure application (and set under maximum angle) showed shallow mixing of soil conserved as much N as a chisel plow, but retained 30 percent more residue at the surface in corn grain systems (Ketterings et al., 2013).

Shallow Disc Injection in Perennial Crops

While injecting and incorporating manure in annually cropped fields is common, it is more complicated in perennial hay fields. Until recently the options were to spread on the surface and accept significant ammonium-N loss, as well as risk of P losses (and higher P-Index scores); or inject using equipment that was designed for annually cropped fields that could damage the stand and create conditions difficult for subsequent harvest operations. Newer shallow disc injection technology has allowed direct injection in perennial grasses and alfalfa without those disadvantages. Initial concerns about the discs damaging alfalfa crowns and negatively impacting yields have proven unfounded. Yield response of older grass and alfalfa stands to these manure applications was positive, while newer high-yielding alfalfa stands were not impacted (Sadeghpour, et.al. 2017).

Manure additives

Several commercially available products are designed to increase availability or preserve manure nutrients. Many of them also purport to prevent crusting and reduce odors associated with spreading. Before investing in these products, it is important to understand which conditions they are designed to work in and what potential problems they may mitigate. In the end, the best bet is to apply manure at agronomic rates to growing crops with good soil health and nutrient management strategies.

Additional benefits

Sound manure management has benefits beyond good nutrient stewardship.

- Maximizing N efficiency allows lower rates of manure per acre, which can mean spreading manure nutrients across more fields, reducing the need for fertilizer across the farm.

- Injection or timely incorporation of manure not only maximizes nutrient retention, but will lower P-indices dramatically, allowing more flexibility in choosing which fields receive manure.

- Similarly, applying manure during the growing season and in split applications will allow for lower P-indices and address risk in high-nitrate-leaching soils.

- Many of the practices outlined in this article are also aligned with reducing the odors associated with manure spreading. This along with drag hose applications can help with neighbor relations, decreasing the off-farm ‘nuisance’ factors of odor and manure tanks on the road.

- Whole farm nutrient balances will improve when nitrogen is fully utilized and off-farm inputs can be reduced.

- Good manure nitrogen management can also equate with lower greenhouse gas emissions. Maximizing crop uptake of N will reduce N2O losses from the actual manure application and avoid N2O emissions associated with fertilizer that is no longer needed.

Summary

- Know the nutrient content of manure and know how much is being applied (sample and calibrate.)

- Apply manure during the crop growing season whenever possible and get it incorporated quickly. Most of the ammonium-N loss from manure applications happens within the first 24 to 48 hours.

- In perennial crops, split applications make the most sense and will pencil out, especially this year with fertilizer prices high.

- Take credit for previous years’ manure applications for N.

- Sound manure management has many benefits beyond reducing fertilizer costs – including more flexibility in your nutrient management plan, good neighbor relations, and environmental compliance and sustainability.

- Manure is a valuable nutrient asset – protecting it will benefit your bottom line, your soil health, and your farm’s environmental footprint.

Factsheets and resources

Cornell Agronomy Fact Sheets are posted online

#4 – N Credits from Manure

#16 – Application of Manure on Established Alfalfa

#18 – Calibrating Manure Spreaders

#38 – Manure Sampling, Analysis & Interpretation

#42 – Manure Use for Alfalfa-Grass Establishment

#53 – Manure Cost, Value and Time Management Calculator

#61 – Valuing Manure N, P, and K Applications

#67 – Can Manure Replace the Need for Starter N?

#76 – Manure Use for Soybeans

#87 – Liquid Manure Injection

Manure Cost, Value and Time Management Calculators

Other citations

Greg Godwin, Quirine Ketterings, Karl Czymmek, Todd Dumond, and Doug Young. Nutrient boom allows for mid-season manure application in corn. What’s Cropping Up? August 2018.

Quirine Ketterings, Greg Godwin, Peter Barney, Joseph Lawrence, Brian Aldrich, et al.. Shallow mixing of surface soil and liquid dairy manure conserves nitrogen while retaining surface residue. Agronomy for Sustainable Development.

Amir Sadeghpour, Quirine Ketterings, Gregory Godwin, and Karl Czymmek. Impact of manure injection on alfalfa and grass hay stands. What’s Cropping Up? December 2016.

|

This article appeared in PRO-DAIRY's The Manager in March 2022. To learn more about Cornell CALS PRO-DAIRY, visit PRO-DAIRY. |

Upcoming programs

Herd health and nutrition conference

Presented by PRO-DAIRY and NEAFA

The Herd Health and Nutrition Conference is a two-day event for agriservice personnel, feed industry representatives, veterinarians, and dairy producers, featuring educational topics related to current herd health and nutrition management techniques. Registration is now open and sponsorship opportunities are available.

Visit Pro-Dairy

When: April 4 - 5, 2022

Where: Doubletree by Hilton

East Syracuse, New York

On-demand online courses

Transition Cow Management and Calf and Heifer Management

The Transition Cow Management and Calf and Heifer Management online, on-demand courses offered by PRO-DAIRY cover basic principles led by Cornell University faculty and staff and industry researchers. They are designed for dairy business on-farm personnel (owner or employee) seeking to increase their knowledge. Participants should possess a formal or informal background in dairy cattle management, but not necessarily in transition cow or calf and heifer management. The On-Demand course includes recorded video lectures and weekly quizzes. You may begin the course whenever you want and will have six months to complete it once enrolled.

Visit Pro-Dairy