Many recent forward-looking articles have shared the central themes that uncertain availability and rising costs are expected to drive 2022 input costs near or above historic levels.

The clear majority of what we have seen or read recently has been focused on row-crop production. However, like you, I know haymaking and forage production are not immune to these factors and are very much relevant to the conversation. My purpose here is not to address the cause, but rather to lend some practical advice that might help producers manage through the volatility.

The one thing that’s not going to change is: Animal production requires feed, and maintaining forage quality is central to maintaining animal health and performance. Simply put, when livestock consume quality feed, they produce quality results. The first thing to concern yourself with is making, storing, then feeding the highest-quality forages you can. When livestock operations feed quality products, they lower production costs, and that can benefit their bottom line.

It could be said, “Haymaking is always an argument with Mother Nature.” Since you can’t win that argument, consider doing things differently to improve the outcome.

1. Start with the basics, before your first hay cutting. While many mower-conditioners share common adjustments, they are not universal. Re-read the field adjustments section of your operator’s manual and inspect your machine settings. Improperly adjusted roll gap and roll pressure (roll tension, as it’s sometimes called) can leave your crop overconditioned, increasing field losses, or underconditioned and slow to cure. It’s simple: Prolonged drying exposes your crop to increased plant respiration, which can lower quality and expose you to greater risk from unforeseen adverse weather.

2. When you cut matters, so cut when quality and yield are right and the weather cooperates. With busy schedules, this is easier said than done. Remember, cutting early can improve quality while lowering yields. Cutting late improves yield but may compromise quality. If you need to plant a new stand, work with your seed supplier to get the best variety for your conditions and your situation.

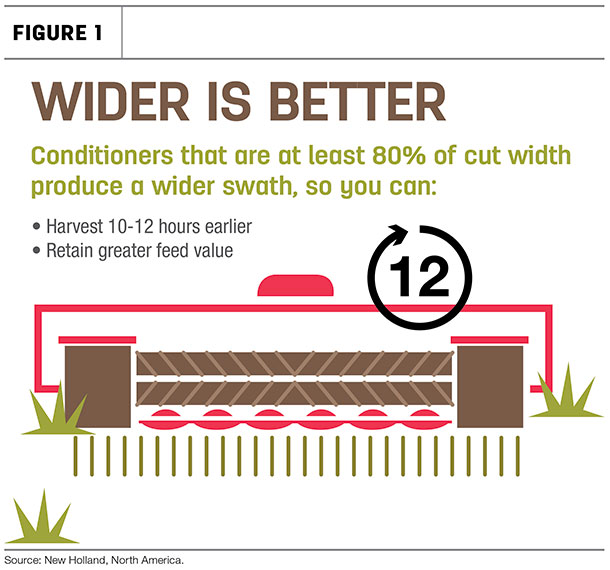

3. Try new things if you have struggled in the past. If your operation has struggled with early or late-season production due to unfavorable weather, trying something new can be a game-changer. To preserve alfalfa, the number one quality rule is to avoid unnecessary crop handling. However, if you’re struggling to dry down, consider trading off a narrow windrow for a wide swath. The drying advantages of a wide swath are clear. However, a true wide swath is likely too wide to pick up directly, and that increases handling.

4. If there is unexpected rain on the horizon, consider trading mechanical losses and a faster harvest in place of rain damage and leached quality. Studies reflect that dry matter losses from 1 inch of rain on an alfalfa crop cured for one day can be upward of 15%, and 1.6 inches of rain over several days can result in significant dry matter losses of nearly 40%. Consider tedding your crop if you have a machine available. The mechanical lifting and separating can mean faster curing. However, if the crop has already cured for several days, it’s likely too late. P. Savoie suggested in his 1987 paper that alfalfa field losses could be as low as 4% but cautioned not to ted alfalfa below 60% moisture, as losses increase dramatically. Remember: A tedder is not a tool to “knock the rain off,” especially when it’s nearly or fully cured alfalfa. At that point, it’s too late and the damage is already done.

5. Packing a tight bale delivers dollars to your bottom line. The logic is simple: When you increase bale density, you put more hay into every bale. For the same tons harvested, you have fewer bales to move, haul, stack and feed. At the end of the season, you have spent less time moving bales, put less fuel in trucks, consumed less net or twine and paid less labor to get it all done.

6. Density delivers higher retained forage quality. A dense, dry hay bale resists weathering better and retains higher quality than a loose bale. Packing a dense silage bale (baleage) excludes more oxygen. When wrapped, temperatures remain low, greater quality is retained, and the finished bales have a lower pH, indicating proper fermentation under anaerobic conditions and prolonged forage stability.

7. Always wrap bales as soon as possible. In as little as 24 hours, unwrapped bale temperatures can reach 120ºF. While there is little risk of bale combustion, you’re still burning money. When bale temperatures rise, crude protein (CP) becomes unavailable to livestock. Quite simply, the penalty is increased feed costs or decreased animal performance. Dry hay producers should be keen to remember this is not unique to silage hay. Baling dry hay at higher moistures that increase bale temperatures will result in the same outcomes.

With growing costs per acre to till, seed, spray, fertilize, then harvest, your bottom line depends on best practices to maintain the quality you have grown into your crops.