More and more dairies are using drone technology to measure the size of their forage piles and more accurately estimate the amount of feed they have in inventory for the next year. The technology is enabling dairies to get within just a few days of predicting when they may run out of feed. That could be particularly helpful to others this year in drought-stricken areas where forage tonnage has been lighter than usual.

“We’re typically within one to three days of estimating when a dairy will run out of feed at a definitive point in the future,” says Derek Wawack.

For Wawack and about 1,000 farms, using a drone and cloud-computed data calculations for forage pile measurement is replacing previous estimation methods. That includes measurement wheels, surveying equipment, hand calculations or just broad percentage reductions from the total forage tonnage harvested.

How it works

A licensed, unmanned aerial pilot flies over a silage pile with a quadcopter drone equipped with a high-definition-resolution (HDR) camera. The drone takes images of the pile – its height, contours and any side walls – and saves them to a memory card on the drone. When the drone lands, the images are uploaded to a commercial cloud-computing service that translates the images into a digital representation of the pile’s shape.

Drone pilots, like Wawack, then receive back the images and can manually review that the detected imagery has only included pile boundaries and not imagery that is not actually forage. This essentially provides the cubic volume of that captured image’s shape. But that’s not the end.

Forages can be packed at various densities (measured in pounds per cubic feet). To estimate how much feed could be stored in that cubic volume, an estimated density must be added to the equation. Wawack says that due to safety concerns related to large silage piles, they aren’t testing forage pack densities. Rather, they estimate inventories for producers based on a range of different pack densities (from 14, 16, 18, etc. pounds per cubic foot).

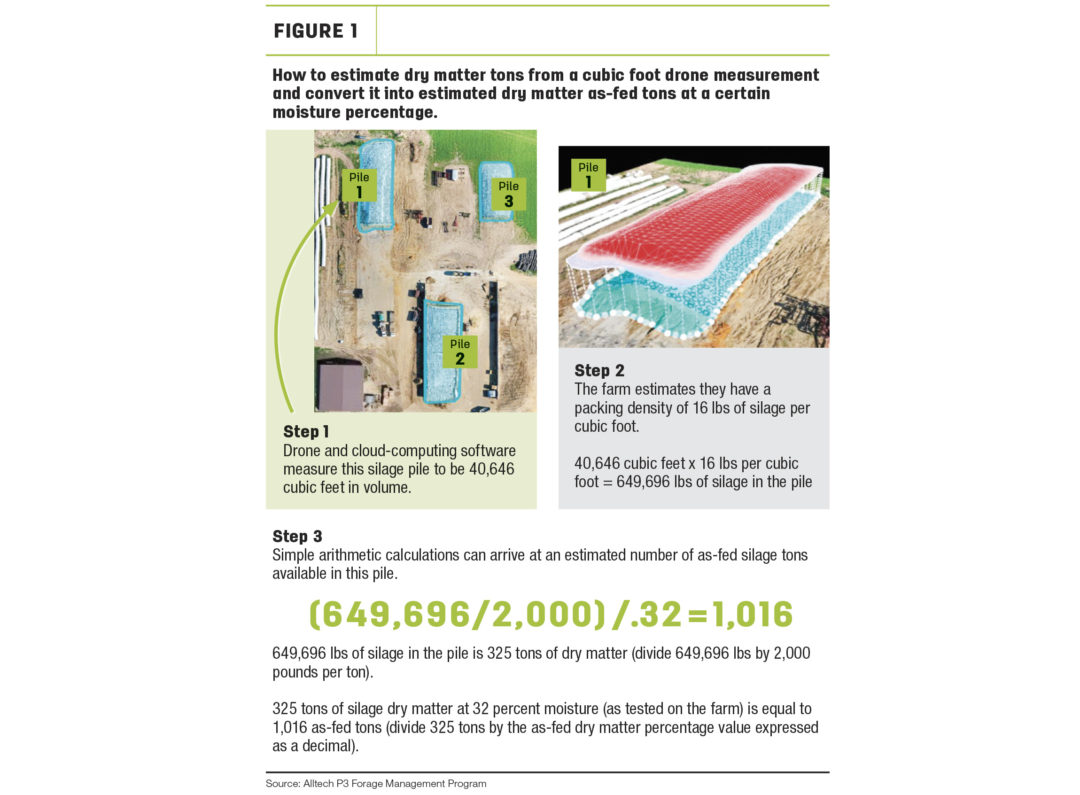

Wawack says usually the farm has an idea of what their pack densities have been in the past. Applying the estimated pack density, one can use the estimated cubic foot produced by the drone and the cloud-computing software to do some simple math calculations and arrive at an estimated as-fed tons held in storage (see Figure 1).

Because the math is so simple, other producers have tried to use their own drones and image-processing subscriptions to arrive at the estimated cubic feet available in a pile. The secret sauce for Wawack and his team is the tinkering they’ve done with the cloud-computing software they subscribe to that has dialed it in to specifically measure silage versus, say dirt mounds or gravel piles.

Technology to measure forage piles is a carryover from technology used to measure large piles of construction material such as sand, rock and gravel. What a drone sees and captures is essentially the same for a pile of gravel as a pile of silage. The biggest difference in calculating cubic feet of the two substances is density. When it comes to inorganic materials, density is mostly fixed. With organic substances, like silage or haulage, density changes based on packing pressure.

“A farmer or the average Joe could go out and buy a computing program. They could get their unmanned aerial pilot’s license. They could get the right drone. But every farm, feed dealer or nutritionist that’s gone out and tried to do it so far has typically come back to us and said, ‘We don’t know what we’re doing. Can you just come out and do it? Because it takes you five to 10 minutes to do it and then we get a report in a day or two later,’” Wawack says.

There are cheaper versions of cloud-computing software available to producers, Wawack says, than the one Alltech subscribes to, but they don’t seem to be as accurate. Alltech helps spread the cost of the more expensive, but also more accurate, software program among its on-farm forage management consulting clients to make it more affordable per instance of use.

“We’ll just say it’s pretty expensive,” Wawack says about the cost of the subscription. “You can buy a cheaper version or a different program, but we’ve found they are just not as accurate.”

A do-it-yourself approach from a Midwestern dairy farm is how Wawack and Alltech first stumbled into measuring silage piles with drones and technology.

Dairywoman Shelly DePestel of Daley Farms in Lewiston, Minnesota, says her husband, Dean, bought a drone to use to take aerial photos with during their silage harvest season. Dean doesn’t work on the dairy day to day. He is a full-time mechanical engineer. One day Dean came to his wife and said he had read online that the mining industry was using drones to estimate the size and volume of tailings piles. He wondered: Would that work for measuring silage piles? Sounds like it could?

He found the cloud-computing software service that Alltech now uses to process his drone’s photos, signed up for a free three-month trial subscription and sent them images of their silage pile. They got their first rough estimates of forage inventories when the results returned. Later that same year, and after the trial subscription was up, the dairy was running low on haylage due to winterkill that spring.

“We were like, “Are we going to make it? Do we need to stretch out our inventory? Should we be looking for another source?” Shelly recalls.

They purchased a full license to the subscription to get serious about using it to help them understand their feed situation.

“We did it for just that one year, but I tell you that was money well spent,” Shelly says. The dairy didn’t end up needing to buy more feed. They only bought the subscription for the one year. Wawack found out about what the DePestel’s were doing and started investigating how to use it.

“Once you get the densities figured it, it’s really been pretty spot on,” Shelly says.

One of the advantages of having more accurate forage inventory numbers for Daley Farms is that it now helps them make the decision in the fall about exactly how many acres of their corn they should chop and put up as silage versus plan to sell as dry corn. In the past, they would have just put everything up as silage to make sure they would be long on feed. But with more accurate inventories, the dairy feels more confident converting some of their crop to a commodity that can wait for an optimal time to market and then convert it into cash flow.

Managing forage inventories is also of interest to bankers. Some banks are requiring feed be listed as an asset on the balance sheet. Having accurate feed inventory numbers is pleasing lenders. It’s also helpful to nutritionists.

“Twenty-five years ago, I used to walk a pile and count steps and assume a 3-foot stride. It’s also a lot easier than going over a pile with a measuring wheel,” says Scott Ellinghuysen, the DePestel’s nutritionist. “I think we were good guessers before, but we really didn’t have firm numbers like we do now. As far as accuracy goes, it’s fantastic.”

Ellinghuysen says from what he’s seen of numbers coming from the program, it’s also more accurate than just guessing inventory based on weighing inventory as it goes in for packing and then guessing on a shrink percentage.

“I sure don’t miss measuring piles when it’s 20 degrees below zero in January in order to try to decide if we’re going to make it on feed until May or June,” Ellinghuysen says.

On most farms, Wawack says the piles are flown twice a year – in the fall to give an inventory estimate and months later after the pile may have settled and shrunk a bit to update the accuracy of the inventory.

Drone flown and cloud-computed silage inventories have been well received in Wisconsin and Minnesota and the I-29 corridor, Wawack says. There’s also growing interest in California, Texas and New Mexico.