Silage is not immune to the many challenges we face on the farm, and the risks begin before it even becomes silage. Agronomists do their part in helping you grow an excellent crop that should yield excellent feed for the coming year. Feed gets a very small opportunity to be made correctly, setting the stage for performance for the rest of the year. Exceptional crops can produce either good or poor feed, depending on processing from field to feedout. Management plays a crucial role in silage making, but systems at work that we cannot see with our eyes make it difficult to influence feed quality.

Wild yeasts are one of those threats to making quality silage that we cannot see but are present in every crop. These microorganisms are found on the plant, but we have little understanding of where they come from and which conditions are most favorable for them. Until we find them in already-fermented corn silage, there is little indication of their presence. Wild yeasts are made up of many different strains, which can grow with or without oxygen, even in low pH, making them very difficult to control and, in turn, leading to extensive damage to silages and dry matter retention.

During fermentation and feedout, yeasts consume the most valuable components of the feed, such as protein, starch and sugar, leaving you with lower-quality feed. If that isn’t damaging enough to the silage quality, when high-yeast feeds are fed, heating occurs from continued yeast growth consuming the same highly digestible portions of the mix. Additionally, even if only one portion of the TMR mix contains high levels of yeast, it contaminates the whole mix.

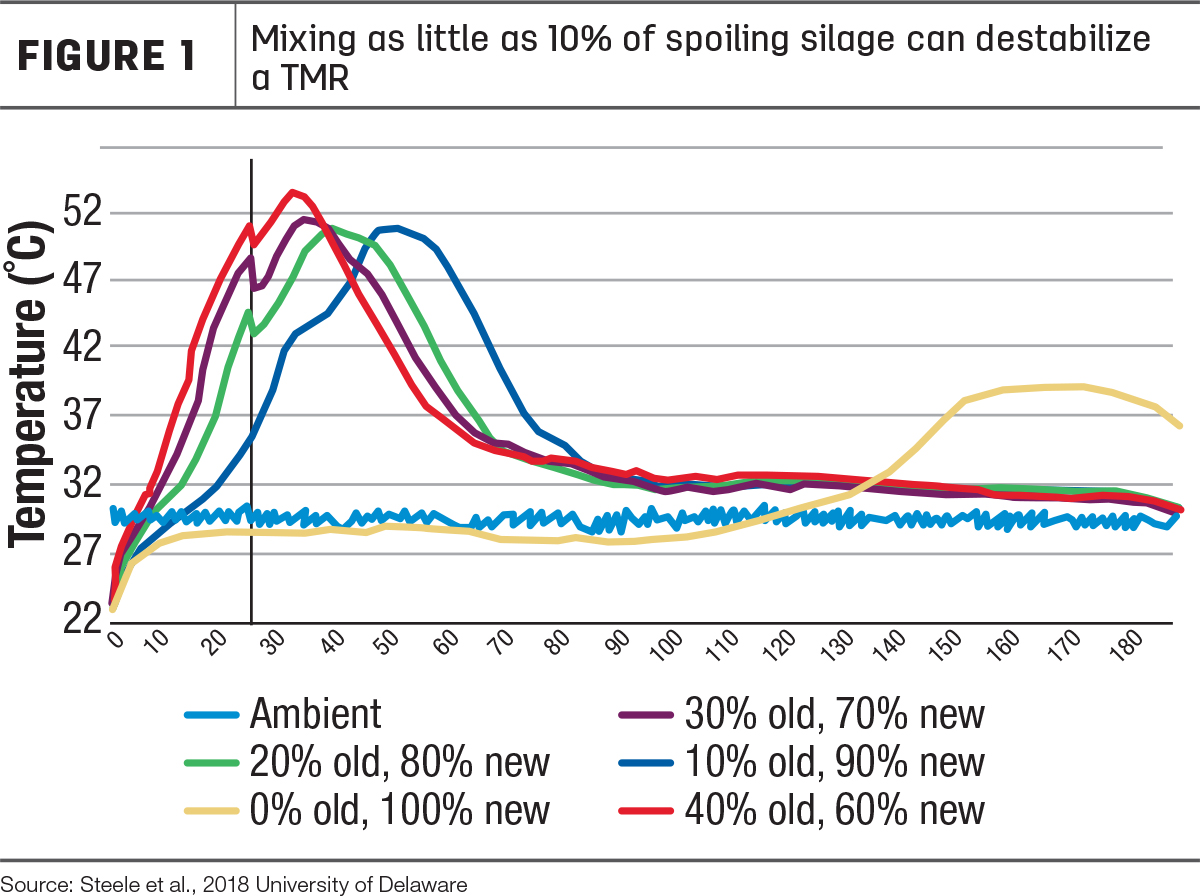

Dr. Limin Kung from the University of Delaware completed a trial testing the inclusion of various levels of spoiled, high-yeast silage, with clean silage measuring silage stability. Clean forage had less than 4,000 cells of yeast, while the spoiled silage contained 40 million cells of yeast.

In Figure 1 from Kung's study, you can see that as little as 10% inclusion of spoiled feed greatly impacts feed stability, dropping it from 140 hours to less than 24 hours. These decreases in stability are likely multiplied during warmer weather. Aerobic or feed stability is the measure of time during which silage remains stable without spoiling after being exposed to air. The longer feed can go without heating, the more stable it is. Although most silage removed is eaten within 24 hours, more hours of stability indicates a cleaner, higher-quality silage that went through a good fermentation.

What most people don’t talk about is the culprit behind decreased feed instability. Most blame molds, but really it’s oxygen exposure that reactivates yeasts – which, in turn, wakes up the molds. By the time molds are growing, substantial dry matter loss (approaching 50%) has occurred and will continue if nothing is done to slow its growth.

Our best tool for managing wild yeast is prevention. Testing plants before harvest for yeast levels does not give us a good picture of what to expect in the feed, but there are situations that favor yeast and mold/mycotoxin production, including:

- Plant stress (due to drought, hail, fertilizer deficiency or being blown over or wind-torn)

- Hay and small grains being rained on

- High ash content

- Dead plant material being included with the fresh green cutting

- Poor packing and covering, which leaves an opportunity for oxygen exposure

- Less-than-ideal moisture at harvest, making it harder to remove oxygen at storage

- Poor face management, such as:

- A face that is too large for the number of animals being fed, which will not allow you to take 6 to 10 inches off in the winter and 12 to 14 inches in the summer

- Rough facing with a bucket and/or without the use of a facer or silage rake

- Lifting up on the silage face, introducing oxygen multiple feet into the storage

Every load of silage hauled to the farm contains wild yeast, but how the silage is treated after delivery will determine whether those existing populations will become problematic. Oxygen is the number one factor in microorganism growth, and removing it is key to achieving high aerobic stability and high-quality silage. During the fermentation process, the first step – regardless of the crop or storage container – is to remove oxygen to begin creating lactic acid, dropping the pH. Packing silage removes the initial oxygen, but trapped air is consumed through the metabolism of naturally occurring bacteria. Yeasts, molds and other bacteria proliferate very quickly during this phase. By utilizing a product to scavenge oxygen, yeast and mold growth are minimized early on during fermentation. Without oxygen, yeast growth is challenged and populations are unable to develop.

Some acids have wild yeast-killing capabilities. Butyric acid is one of these acids, but butyric fermentations result from clostridia bacteria, which are very undesirable. Propionic acid, which is found in a lot of bunk stabilizer products, will also kill wild yeast, but it is not an economical option when applying to silage. Acetic acid is the third acid with yeast-killing abilities, and it can be found in any silage after fermentation. This acid is also very important to aerobic stability and halting microbial growth after re-exposure to oxygen. For these reasons, bacterial inoculants containing L. buchneri have been popular treatments for use on forage. L. buchneri bacteria convert lactic acid to acetic acid after 45 days of being in storage. However, not all L. buchneri inoculants are created equal. Dr. Limin Kung’s research shows that 500,000 cells per gram of L. buchneri should be applied to silage for the best control of wild yeasts and to optimize aerobic stability.

In a perfect world, being able to test for these unwanted organisms before ensiling would allow us to prepare for less-than-ideal silage. Since we cannot do this yet, crop and silage management are our best defense. Filling silage storage quickly with clean plant material that is tightly packed minimizes the risk of yeast growth and boosts the likelihood of producing high-quality feed. Utilizing a proven preservative or inoculant is essential to reducing microbial growth and retaining the feed grown in the field to the bunk.