“Our cows are only as productive as the feeds we produce for them.” There is nothing closer to the truth. Feeds and forages are the foundation for high-producing dairy rations and often determine our ability to achieve the optimal efficiency in milk production.

Furthermore, as a contributor of up to 60% of a cow’s dry matter intake (DMI), no other ration component is more impactful on marginal dairy profitability than forage quality. Evaluating if we have succeeded at hitting our goals throughout the harvest season can be challenging. It is easy to assess alfalfa haylage quality since it can be measured by relative feed value or quality (RFV or RFQ). Conversely, corn silage value and quality can be a bit more difficult to quantify due to its multicomponent composition of both fiber and starch and the significant impact harvest management can have on the cow’s ability to digest these components. One thing is for certain, kernel processing score (KPS) plays a fundamental role in determining how the corn silage will feed throughout the year.

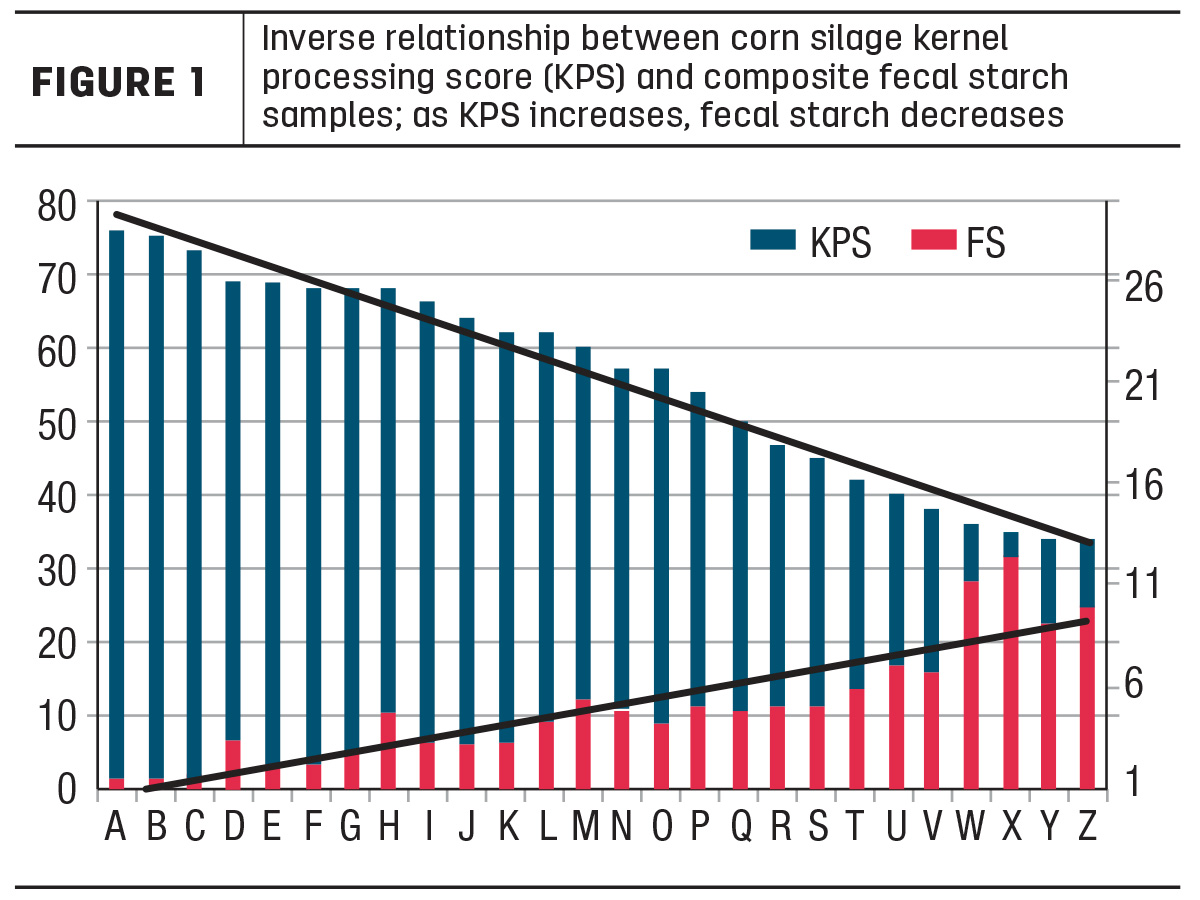

For today’s high-producing dairy cows to optimally digest the corn grain in whole-plant corn silage, the corn kernels must be optimally processed. This is just as critical as the micron size of dried, ground corn or particle size of high-moisture corn included in a total mixed ration (TMR). The KPS of corn silage is one of the best indicators of a cow’s ability to optimally digest the starch in whole-plant corn silage. To evaluate this impact, a few years ago, a field observation was conducted demonstrating that higher KPS of corn silage increased total tract starch digestibility (TTSD) indicated by lower fecal starch (Figure 1).

Bottom line: If improved kernel processing of corn silage reduces fecal starch from 5% to 1.5%, there is energetic potential for an additional 2.5 pounds of milk from the same corn silage.

One might ask, “What should I be looking for when evaluating KPS in corn silage?” Dr. Dave Mertens, formally of the U.S. Dairy Forage Research Center, originally proposed the following guidelines that in general have been accepted industrywide as the standard for KPS:

- Optimum: greater than 70%

- Adequate: 50%-70%

- Inadequately processed: less than 50%

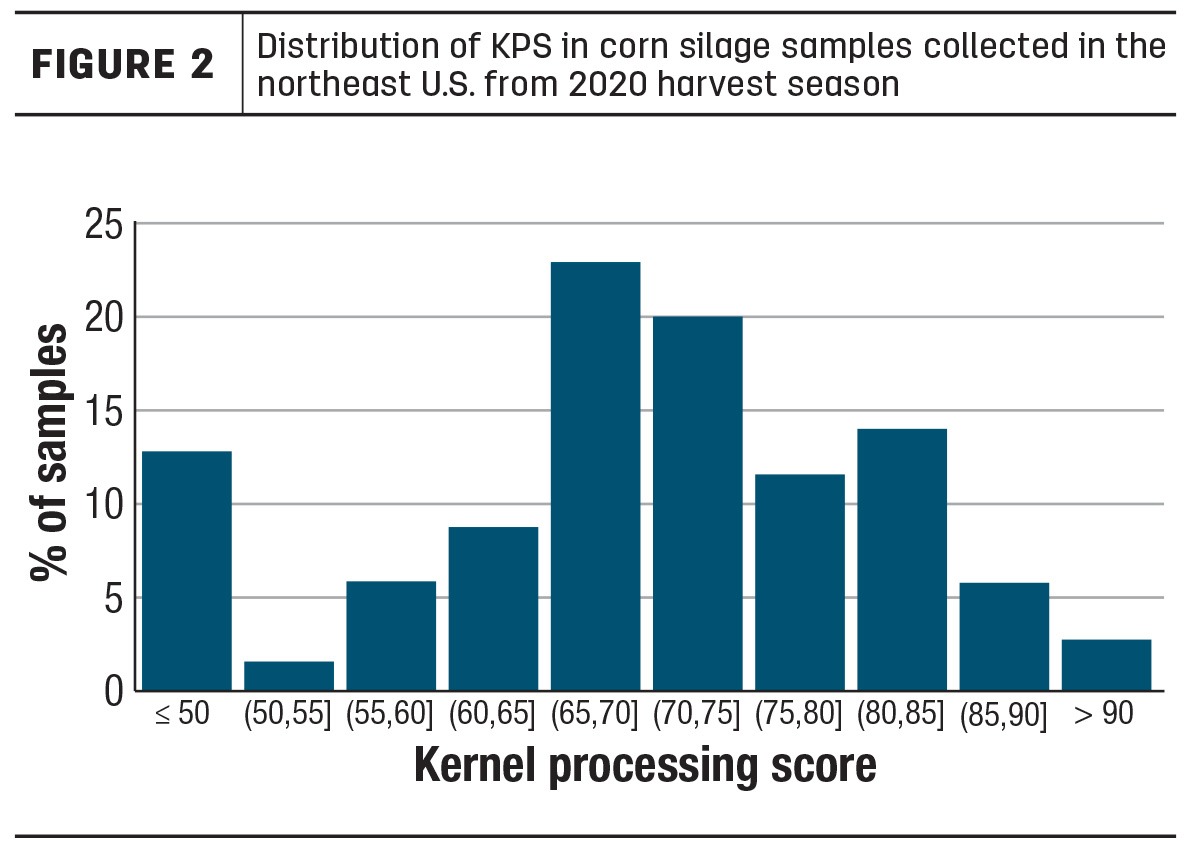

These guidelines have been well accepted, and the optimum is an achievable goal. In the Northeast, corn silage harvested in 2020 had an average KPS of 71% with 50% of samples above the optimum value (Figure 2).

Bottom line: In order to minimize fecal starch and maximize energetic efficiency, corn silage KPS should be above 70%.

What if we miss our harvest target of 70% for KPS can ensiling duration help?

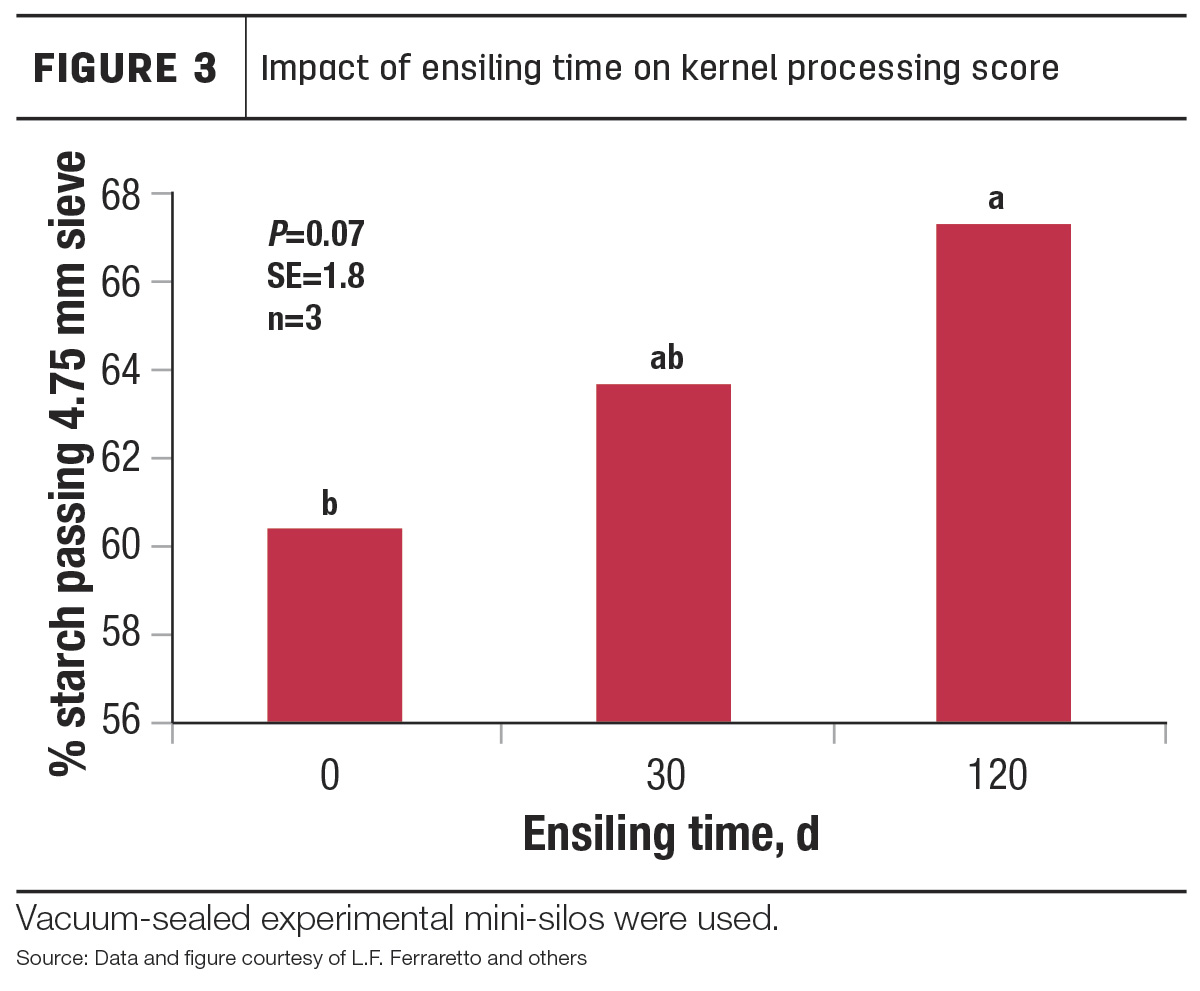

Although harvest is the most critical time to impact KPS, it will improve with time, usually reaching a peak about six months after ensiling. Work conducted by Dr. Randy Shaver’s research team at the University of Wisconsin investigated the effect of ensiling duration on KPS in whole-plant corn silage harvested with varied processors and settings. Dr. Shaver’s research team conducted two experiments to evaluate the impact of: (1) ensiling on KPS of whole-plant corn silage of varied processors and settings and (2) extended ensiling times on KPS of corn silage. In the first study, fermented corn silage had a KPS that was 9.9 percentage points higher than the unfermented samples (60.1% versus 50.2%; P = 0.01). In the second experiment, the samples fermented for 120 days tended to have KPS that were 7 percentage points higher than the unfermented samples, but this difference was not observed after only 30 days of fermentation (Figure 3). This has also been confirmed with field trial data that reported an 8-12 percentage point increase in KPS from harvest through fermentation with greater gains in KPS observed among samples with lower KPS at the start.

Bottom line: During fermentation and in storage, KPS will improve anywhere from 5-15 percentage points depending on KPS coming out of the harvester and duration of time in storage.

What if we miss our harvest target of 70% for KPS and can’t wait for 120 days of ensiling before feeding new-crop corn silage?

In an ideal world, corn silage should be ensiled for a minimum of 90 days prior to feeding; however, that’s not always an option. Fortunately, there is a science-based, research-proven silage inoculant on the market that preserves feed by accelerating fermentation. This novel silage inoculant contains two bacterial strains that work synergistically to reduce spoilage by eliminating residual oxygen and by producing acetic acid, which controls the growth of spoilage microorganisms and increases aerobic stability. In addition to reducing the ensiling time prior to feedout, it also has a positive impact on starch digestibility.

Work conducted at the University of Florida evaluated the impact of grind size and the use of a science-based, research-proven inoculant on the impact of starch digestibility of high-moisture corn (HMC). Samples with a mean particle size (MPS) of coarse (3,797 microns and 14.8 square centimeters per gram (cm2/g) surface area) and fine (984 microns and 33.1 cm2/g surface area), were ensiled and evaluated for in situ starch degradation. Inoculated, coarsely ground HMC had a 10 percentage points higher starch digestibility (32% to 42.9%) compared to uninoculated, coarsely ground HMC. Additionally, work performed in the Netherlands showed an improvement in the starch digestibility of TMRs containing corn silage inoculated with a research-proven, two-strain inoculant containing Lactobacillus buchneri (96.9% to 97.7%). Both of those studies indicate that in the event we don’t hit our KPS goal at harvest, the successful application of an effective, science-based, research-proven silage inoculant can improve the starch digestibility of corn silage.

Bottom line: A science-based, research-proven inoculant can improve starch digestibility of corn silage.

What if we miss our harvest target of 70% for KPS, can’t wait for 120 days of ensiling before feeding new-crop corn silage and didn’t apply a science-based, research-proven inoculant capable of improving starch digestibility?

At this point, we should focus on what can we do to improve the cow’s ability to capture additional energy from poorly processed corn silage. Ensuring a healthy rumen and healthy lower gut should lead to a healthier cow that is more productive. Feeding a research-proven probiotic can be an effective way to ensure the cow has all the tools needed to perform her normal tasks efficiently. Field observations evaluating the impacts of probiotics on starch digestibility have reported that when fecal starch was greater than 2% prior to probiotic feeding, fecal starch was reduced from 5% to 3.4%, and concurrent total tract starch digestibility was significantly improved from 92.8% to 95.1%.Bottom line: Feeding cows a science-based, research-proven probiotic can improve their ability to digest starch from a variety of sources, including poorly processed corn silage.

Take-home message: Even though we do our best to meet our harvest targets, there are a plethora of tools to help us enhance suboptimal harvest KPS and improve starch digestibility of corn silage and high-moisture corn.