A cow’s core body temperature can rise very quickly in the holding pen without a cooling strategy in place. Therefore, the cooling strategy for the parlor and holding pen must be more aggressive to compensate for these heat abatement challenges.

The holding pen is generally designed for 15 square feet per cow. Compared to normal stocking rates in the barn, the BTU per hour per square foot (BTU/hr/sq. ft.) of occupied space is 6.5-times higher in the holding pen than the barn she just came from. Since cows are in closer proximity in the holding pen, there are also more opportunities for heat transfer between cows. Direct skin-to-skin contact for conduction of heat is at net zero since the cows on either side have similar skin temperatures. Convective heat loss can only be achieved by driving airflow down around cows, combined with soaking and, where applicable, high-pressure fogging. Additionally, heat and humidity from the cow’s respiratory tract is also being added to this equation. Larger holding pens resulting from larger pen sizes increases the risk of driving core body temperature above 102.2ºF (39°C).

Cool your cows, save your calves

The most obvious consequence of heat stress is reduced milk production. However, the hidden cost of heat stress for this short time in the holding pen may be robbing your dairy through early embryonic death. Within the early post-conception period, the embryo is highly susceptible to elevated core body temperatures and lacks a protective protein that does not develop fully until five days later. Research indicates a 7% reduction in conception for each 1°F rise in core body temperature and embryonic loss being 3.7% higher in summer than winter. Anecdotally, dairies with great barn cooling strategies have seen improved reproductive performance by incorporating more-effective parlor and holding pen cooling.

Looking into the parlor

It is generally recommended to set parlor airflow in alignment with the prevailing winds that occur during periods of heat stress. It is best to move fresh air from the parlor into the holding pen since the cleanest air should be where we are harvesting food. If the airflow originates in the holding pen and then goes into the parlor, heat, humidity, hair, dirt and dander are directed into the food harvesting area. Forcing fresh air into the parlor to achieve a 60- to 90-second air exchange during heat stress periods is common, and incorporating recirculation fans appropriate for the space to drive air onto the cows is recommended regardless of parlor style. Employee comfort can also be achieved with this strategy.

Some dairies use an additional soaker system over the deck of parallel parlors or spray wands in rotary parlors located after the unit attachment zone and again near the exit. If these are used, water should reach from the shoulder to the loin but not run down the back of the udder. Having water on the udder increases the risk of mastitis. Soaker nozzles should spray no closer than approximately 20 feet from the parlor entrance. Aggressive airflow in this area will allow the cow to enter the parlor with no water dripping onto the udder region.

Designing the holding pen

The air being forced into the parlor is then added to the air exchange rate for the holding pen. The use of curtain sidewalls and recirculation fans over cows in the holding pen has been a traditional strategy, but this approach has been found to be less effective. Recirculation fans must be positioned closer to each other laterally and longitudinally down the holding pen compared to what is generally used in the dairy barn. It is recommended that fans are placed laterally no more than three fan diameters apart to achieve air speeds in the 5-plus-mph (200 meters per second) range over the cows. The amount of air being moved in cubic feet per minute per cow (cfm/cow) should be at least 1,000 cfm/cow and preferably greater than 1,500 cfm/cow. This is fresh air exchange, not recirculation fan capacity. These recirculation fans should be directed to drive air down onto the cows along with the soaker and high-pressure fogging strategy. The use of fresh-air injection fans has become more common in holding pen designs. High-pressure fogging, under appropriate conditions, can be added to these injection fans to drop ambient air temperature as an adjunct to the primary soaker system. Depending on the approach, either exhaust, passive exit or a combination of the two can be used to ensure air exchange and the removal of heat and humidity from the holding pen. Sidewalls are generally closed with curtains or permanently with polycarbonate material, which creates a more-controlled environment.

Cross-vent vs. tunnel-ventilated holding pen

Studies have shown that tunnel airflow down the length of the holding pen is less efficient in reducing the core body temperature of a soaked cow and requires about 50% more air speed to achieve the same cooling rate as air directed toward the side of a cow.

The cross-vent approach means air is entering the holding pen sidewall and exiting after being directed perpendicular to the cow's stance. In theory, this should be better than the tunnel approach in the holding pen. Without redirecting recirculation fans, this approach is not effective since the air will be deflected up and over the cows by the crowd gate support wall, or with open gating, it will be deflected by the outside row of cows.

Both design approaches require a recirculation fan design element, and including an automated control system to regulate fans, soaking and high-pressure fogging, if appropriate, is essential.

Put it into practice

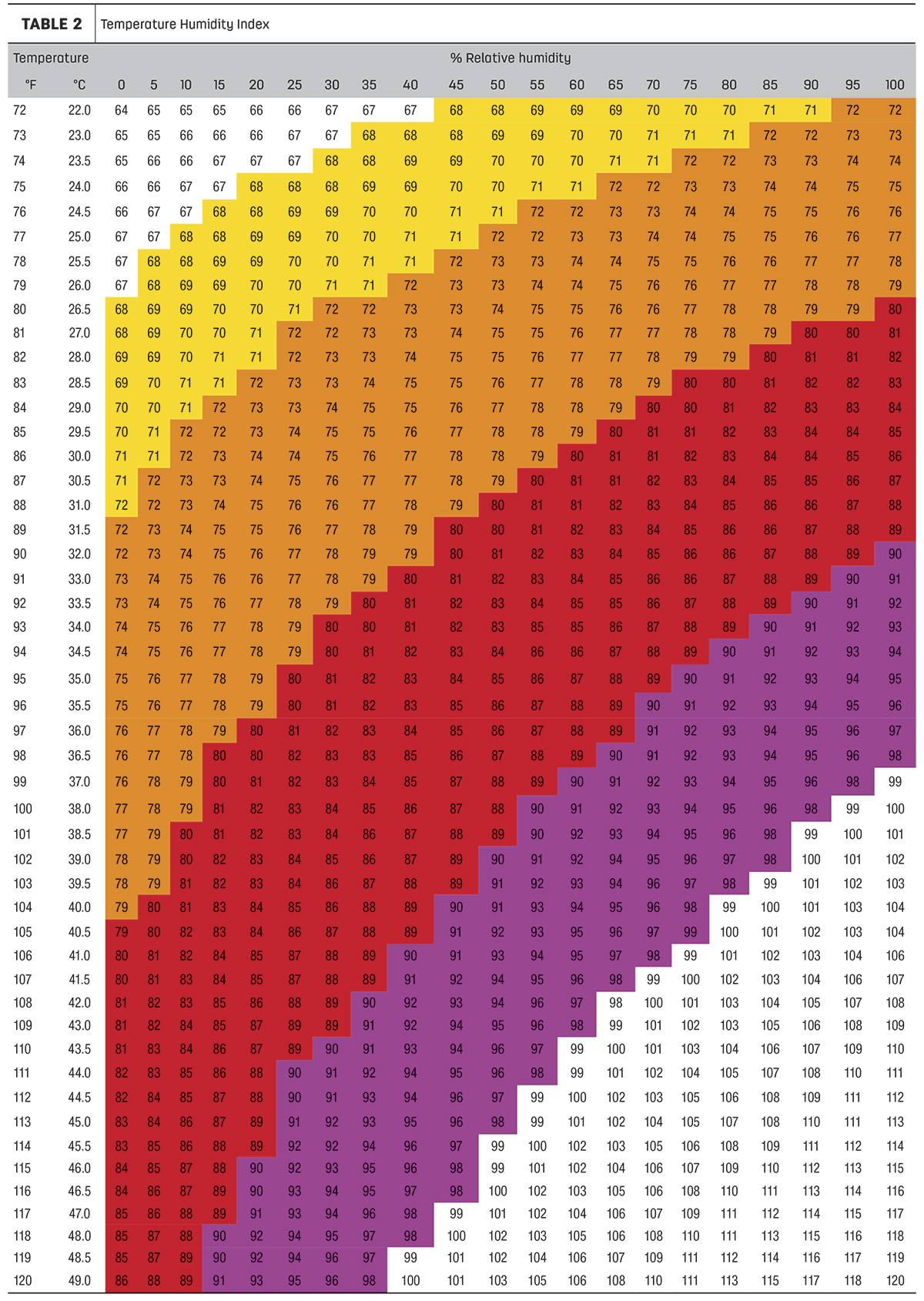

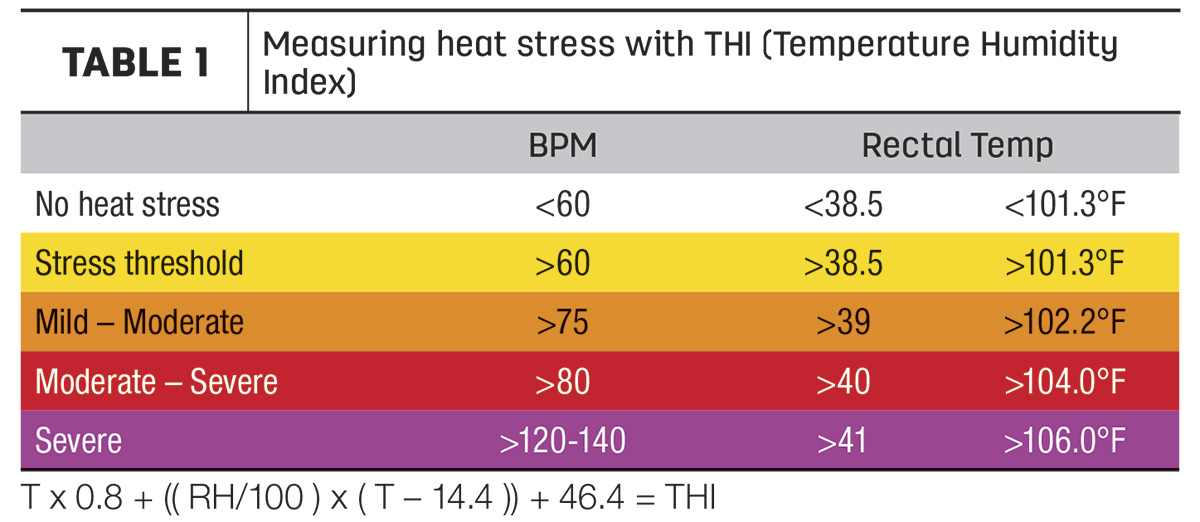

Cooling effectiveness can be achieved by observing breaths per minute (BPM) or by taking rear udder temperature with an infrared sensor (Tables 1 and 2). A BPM measurement over 60 indicates raised core body temperature, and a rear udder temperature greater than 94°F (34.5°C) is the threshold for a core body temperature of 102.2ºF (39°C). Monitor the higher-production cows as they enter the parlor, as checking on them will indicate how well your barn cooling strategy is working.

Are you cooling cows effectively where the cows spend most of their day? Next, monitor the middle third of the group to see if their core body temperatures are higher or lower than the first group in the parlor. Finally, monitor the last third for the same trend.

There are multiple considerations when developing an effective and efficient parlor and holding pen design that will cool cows in one of the most critical areas of the farm. I encourage you to work with experienced and qualified ventilation consultants in creating the design that will work for your dairy.