TRENDING TOPIC ARTICLE: A.I. & BREEDING Published: December 12, 2011 Progressive Dairyman print issue In this past article, Lyle Kruse, vice president of U.S. market development at Select Sires, details the company’s development of Select Detect. to jump to the article.

The company collaborated with Dairymaster to create a heat detection system in which activity monitors use accelerometer technology to track activity using fine-tuned mathematical equations.

Because this article was so popular, we asked Kruse, “What challenges lie ahead regarding widespread adoption of activity monitoring systems, like Select Detect, by producers across the country?”

Kruse provided these responses:

- There is currently a broad level of interest in the U.S. dairy industry investigating this technology. The investment of an activity/health monitoring system will have a different level of return on that investment for each operation. To maximize the investment, it is important to have monitors at the right cows in advance of the events you want to measure to build the baseline for that activity.

- If you are going to invest in an activity system for cows, it is critical that you work with someone who has the expertise to help you manage the system properly including how to best utilize synchronization in combination with the activity system technology to maximize your results.

There will be a percentage of cows that will need some hormone intervention to assist them in overcoming anestrous status and a high-performing activity system that provides accurate heat detection will help you eliminate the cows that are cycling, so you can focus individual intervention on the cows that need it.

That is why it is critical who you purchase your activity system from. A Select Sires reproductive specialist can help you maximize your investment in an activity system in the same way that a milking equipment specialist can help you maximize milk harvest with the investment in new milking equipment, so work with specialists within their field of expertise.

- With the escalating cost of rearing replacement heifers, it is critical that a high percentage of heifers become pregnant as soon as they are deemed to be of sufficient size and age to be bred.

An activity system has become a great option for heifer reproduction as heifers are often a neglected segment in the operation and the addition of an activity system can help get heifers inseminated at the correct time, with a high percentage getting pregnant without addition intervention.

- There will continue to be improvements and enhancements to motion-sensing and health monitoring systems, so it is important that you make the right choice for the equipment that best fits your needs.

There are some options that are outdated and will not provide enough accuracy to rely on as a sole means of heat detection. Conversely, there are some options that have not been thoroughly tested in the wide variety of U.S. dairy operations and may not be a good fit for your operation.

- We are continually monitoring new products and enhancements to be certain our product monitors those activities and/or management data that producers deem necessary.

ARTICLE

What factors can cause a demand for change and development of new technology? In the past, public opinion and the lack of new technology have led to improvements and innovations in the livestock industry.

The main driver for the creation of Select Detect was this exactly – the need for a reproduction management alternative.

Lyle Kruse, vice president of U.S. market development at Select Sires , explains that at a long-range planning meeting in 2008, the company’s board of directors challenged its staff to find alternatives to estrous synchronization in dairy cattle reproduction.

This was mainly because, at that time, hormone use in livestock had fallen under scrutiny, causing the use of one specific growth hormone to be limited.

“The concern was what would happen to A.I. usage if the same limitation was placed on reproductive hormones,” Kruse says. “Even though we know that this threat is not eminent, the question remains in the back of our mind.”

Finding the right system

Staff members, including Dr. Ray Nebel, vice president of technical services at Select Sires, set out to look at the different automated heat detection systems available and provide producers with another option in the reproductive management of their herds.

“We looked at several systems including Dairymaster’s MooMonitor when we were investigating alternatives and decided to contact them,” Kruse says.

Dairymaster , an Irish-based company, had developed their heat detection system in 2005. Select Sires became interested in the technology behind the system.

The two companies reached a marketing arrangement and in October of 2010, Select Sires launched the product in North America as Select Detect .

This PC-based activity monitoring system boils down to precise math and science. Kruse explains that the product developers placed the monitors on the cow’s neck and tracked the activity collected by an accelerometer and compared those same movements with video sensing.

“They used video imagery to record the various movements of a cow and determine exactly which ones they wanted the monitors to measure,” Kruse says. “This filtered out extraneous movements that wouldn’t help detect high activity.”

The activity monitors use accelerometer technology to track activity using fine-tuned mathematical equations that were configured based on the video imagery and activity comparison.

The accelerometers are also capable of measuring acceleration and gravity-induced reaction forces, or g-forces, in three dimensions.

“The accelerometer is measuring activity very accurately and internally with a significant number of proprietary algorithms, making it a precise measurement to detect high and low activity,” Kruse says.

Collar maintenance

Kruse points out that the monitor fits snugly on the neck of the cow to remove any extra motion from the collar being too loose. A counterweight also helps keep the monitor properly centered on the neck of the cow.

Once the collars are placed, the producer will need to wait approximately one week for the cow’s routine activity to build her activity baseline. After that, the producer will be able to start using the activity measurements from the monitors.

The collars transmit data via radio transmission to base stations when they are approximately within 300 feet of the station in a clear line of sight.

Kruse notes that a challenge may arise when steel building components interfere with the radio transmission of data from the monitors to the base station. However, he explains that this can be overcome by adding another base station to the installation if needed.

Once the data reaches the base station, it will send a signal to the communications interface box, which is wired directly to the computer. The communications interface box then transfers the information to the system’s software program.

“This product is very user-defined,” Kruse says. “The producer can define how often he wants to upload the monitor’s information, which ranges from every hour to every four hours.”

Kruse points out that this specific system works well in confinement and grazing settings because it was developed in a grazing environment, which he says is one of the most difficult environments to determine high-activity cows from normal movement.

In freestall operations, the base station is usually mounted in the freestall barn. In grazing operations, the base station would be placed in the holding area so that information downloads during milking.

Monitoring event lists

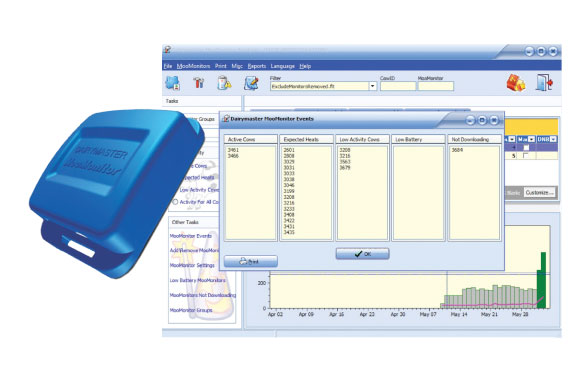

Five different event lists can be generated within the program including active cows, expected heats and low-activity cows.

Kruse defines active cows as those cows that are above their activity threshold. Expected heats are cows that were recorded in the system with a heat 19 to 23 days prior to that day. He points out that these cows aren’t necessarily in heat – they are cows that have a potential return heat based on a normal cycle.

“Our producers with Select Detect can go through that expected heat list, look at a cow’s daily activity to see if she has a spike but didn’t cross the threshold,” Kruse says.

Low-activity cows are cows that have spent a significant amount of time below the low-activity threshold, which Kruse explains can also be defined by the user but is typically 50 to 60 percent of the cow’s normal activity.

“These would be cows that could have mastitis, foot problems or some other health-related problems and would not spend a lot of time moving around,” Kruse says.

Additional options

Kruse explains that the producer can shuffle through the different lists within the software to find the list of cows he needs. The activity information on a cow is presented in a daily and hourly format.

“We call this precision reproductive management because in reality this gives the owner-user a chance to customize how to make this program work for his goals,” Kruse says.

Kruse does point out that a producer should buy enough collars for about 40 percent of his herd, which will allow for the collars to be rotated from one cow to another.

“Unless you’re very seasonal in your calving, this should provide you with enough collars to move through the system from cows confirmed pregnant to cows entering the breeding pen,” Kruse says.

Moving forward

In October, Select Sires and Dairymaster released a mobile application of the Select Detect program, which is optimized for use on an iPhone, iPod Touch, iPad and Android-based phones.

This is currently the only system that has a mobile application available in the marketplace and is available to all Select Detect users as part of the system’s package.

Basically, the mobile application allows dairy producers to monitor their herd’s data without the need of having to sit in front of a desktop computer.

The data is gathered and refreshed on an hourly basis. If a producer lives off-site, he can simply pull up a list of cows that need to be bred before he leaves his home.

With more than 150 systems currently installed in North America, Kruse says Select Sires aims to continue this trend and help dairymen get more cows pregnant.

“We’re not selling this system as the only option, but it’s definitely a good one if you want to catch a lot more cows at the right time,” Kruse says. PD

PHOTO: Producers with Select Detect can go through the expected heat list and look at an individual cow’s daily activity to see if she has a spike but didn’t cross the preset threshold. Photos courtesy of Select Sires.

-

Dario Martinez

- Editor

- Progressive Dairyman magazine

- Email an editor