The shift from conventional to automatic milking systems is one of the biggest decisions a producer can make. Many questions and concerns that come with this decision relate to the dairy’s feed management. Read on for real robot nutrition experience and the best approach to ensure success before, during and after startup in an automatic milking system.

Before start-up

Nutritionally, the homework for a producer, along with the nutritionist, begins three to four months prior to startup when they meet with local farm management support to discuss changes in feed management.

The biggest challenge for the producer and nutritionist may be moving from a TMR to a partially mixed ration (PMR). Changing feeding styles is an important step in transitioning to automatic milking, ensuring cows are motivated to visit the robot regardless of barn layout.

What does a PMR look like? The best rule of thumb is to balance the feedbunk 15 pounds below the herd’s average production. The remainder of the carbohydrate requirement will come from pellets fed in the automatic milking system.

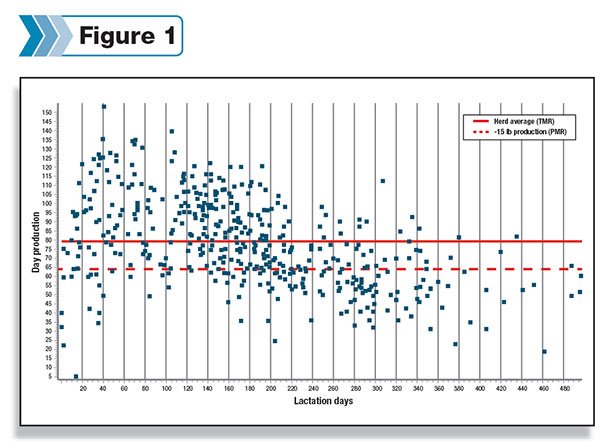

Figure 1 demonstrates the effect a TMR may have on a cow’s motivation to visit the automatic milking system.

If the feedbunk was balanced at the herd’s average production (80 pounds), theoretically any cow below the solid line could be a fetch cow (i.e., the producer has to bring her to the automatic milking system). When the bunk is balanced using a PMR 15 pounds below the herd average (65 pounds), the number of fetch cows decreases.

Figure 1 also shows impressive peaks and persistence throughout the lactation on a PMR and pellet. The key to these impressive results is partially due to the type and quality of pellet fed.

Pellet quality and composition

There are as many forms and formulations of pellets fed in automatic milking systems as there are farms with automatic milking systems, so there is no “silver bullet” to composition. The common thread, however, is that pellet quality and palatability need to be consistently excellent.

Ideally, a “robot pellet” would include starch-rich ingredients. Here are a few reasons why:

- 1. Starch rapidly degrades in the rumen to produce propionic acid, which increases glucose production in the liver and therefore stimulates milk production. Energy from carbohydrate digestion also promotes microbial protein synthesis, which enhances the cow’s nitrogen efficiency compared to cows fed digestible-fiber pellets.

- 2. By feeding cows according to their individual carbohydrate requirement, calories can be allocated exactly based on demands of milk production, stage in lactation and parity.

- 3.Cows which are fed a PMR in combination with a starchy pellet are stimulated to visit the robots as well as the feedbunk.

Cows are attracted to durable pellets with little fines. Not all feed mills are the same and may be challenged when pelleting some starch-rich ingredients, like corn, but other ingredients, such as barley and oats, have good pelleting qualities and still fulfil a cow’s glucose requirement. Pellets leaving the feed mill should have less than 2 percent fines and should ideally strive to deliver feed with less than 1 percent fines.

Feeding at startup

It’s a few days before startup, and everything is ready for the big day. Are the cows ready? Some farms allow for a training period a few days before startup where cows can visit the robot, not to be milked but to find the high-quality pellet formulated for them. This develops recognition that the robot delivers a reward for visiting.

Make the transition into the robot smooth by feeding the PMR and top-dressing the pellets on the bunk before startup. Cows will become acquainted with the change in feedbunk management, and it provides something familiar to taste when visiting the automatic milking system the first few times.

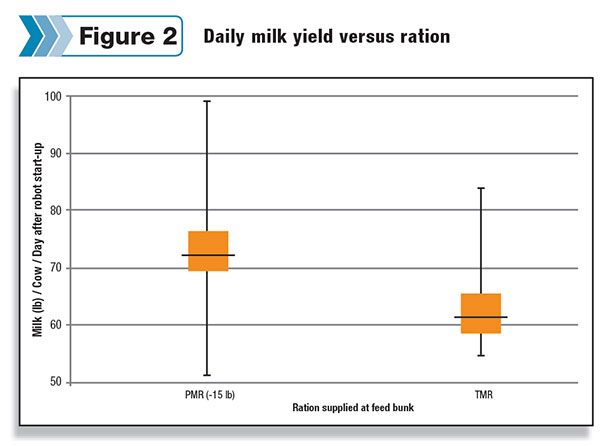

A survey conducted in 2011 by 60 automatic milking system startups echoed the importance of proper bunk management prior to startup and beyond. Figure 2 compares these farms, their bunk management styles and the results achieved the year after startup.

The PMR farms produced 11 pounds more milk than their TMR counterparts on average. The PMR herds had the highest degree of variability, likely due to when or if the PMR was introduced prior to startup.

Fine-tuning after startup

Startup and transition have gone smoothly, and cows are familiar with their new environment and management style. This doesn’t mean the work is done; it is just starting.

After production has stabilized, cows should be moved to a customized feeding table based on days in milk and milk production. Feed tables can be customized by parity or specific group and can utilize single or multiple feed types.

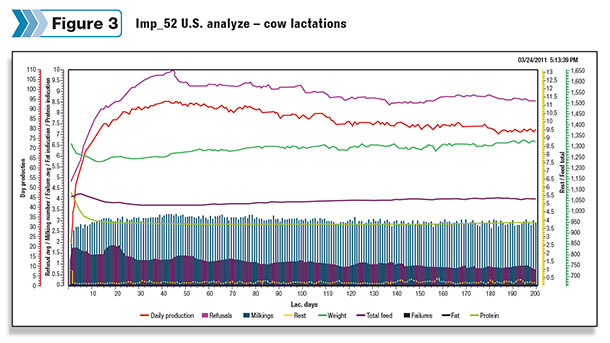

To assess necessary nutritional changes, Figure 3 gives a snapshot of the herd’s performance and visit behavior. Reviewing this type of graph will generate great discussion at dairy team meetings and is a valuable tool to set goals and monitor changes and their effect on the herd.

Use the following questions to facilitate the discussion. To do so properly, it is important to look at the graph in levels: herd level, primiparous and multiparous levels.

- 1. Are cows peaking at the ideal time?

- 2. How does milk production respond to changes in total programmed feed intake?

- 3. Is the visit behavior and feeding of the cows influencing production?

- 4. Is the feed setup in the early lactation stimulating cows to reach their genetic potential?

- 5. Is the bodyweight and energy balance in the early lactation in order, or are adjustments needed in the transition period or the way cows are guided after calving?

Robotic milking may first seem a challenge from a nutritional standpoint. By discussing feed management before startup, giving the right recommendation at the feedbunk and quality pellet in the robot, and providing regular follow-up and fine-tuning, the nutritionist, producer, and most importantly, the herd will be equipped for a successful life in robotic milking. PD

-

Mark Rose

- Nutrionist

- Lely

- Email Mark Rose