When milk prices are high, it sure is tempting to overstock lactating pens in hopes of capturing a few more dollars at the end of the day. But how many cows can you pack in a pen before it affects profitability?

Much like milk and feed prices are moving targets, our data indicates that the maximum profitability per cow per stall is too.

Several studies document the effects of stocking density on some aspect of cow behavior, but few studies provide quantitative relationships between stocking density and cow performance measures that directly affect profitability, such as milk production, milk quality, fertility or health.

Theory of economicoptimal stocking density

Stocking density economics follows the classical law of diminishing marginal returns. This means each additional (marginal) cow will generate an income (milk sales, calf value, cull income) at a cost that varies with the cow (feed, parlor supplies, maybe some labor).

Costs that vary with the cow are variable costs. Costs that are not affected (fixed costs) by the number of cows in the pen – for example, depreciation and most of the labor cost – are not relevant for the question of optimal stocking density.

Every additional cow also reduces the performance of the other cows already in the pen. The economic optimal stocking density is reached when the marginal return of the pen equals the marginal cost of the pen. At this stocking density, the profit per stall is maximized. Add one more cow, and the pen’s marginal return is less than the marginal cost, and profitability per stall decreases.

How we calculatedoptimal stocking density

We developed a spreadsheet of a herd budget that mimics the daily movement of cows through their lactations until they are culled. Examples of inputs are lactation curves, feed intakes, 21-day service rates, probabilities of conception, involuntary culling risk, etc.

We chose our inputs based on plausible values for U.S. dairy herds during the last several years. The herd budget also calculates many statistics that follow from the chosen inputs, such as annual cull rate, average days open and herd milk production, as well as revenues, costs and profit per stall.

In our analysis, stocking density affected milk production and reproduction. The effects linearly increased with stocking density greater than 100 percent. Milk production was reduced by 1.1, 1.5 or 2 pounds per day per cow in the pen per 0.1 greater cows per stall. The 1.5- and 2-pound losses are slightly greater than the 1.1 pound per day reported by researchers in 2008 but might include other not-well-quantified effects such as increased lameness or lower milk quality.

Secondly, probability of conception was reduced by 0.1 per 0.1 greater cows per stall in all scenarios, as found by a study in 2010. A sensitivity analysis was carried out to reveal how the optimal stocking density depended on milk loss, milk prices, service rate and fixed versus variable costs. We varied stocking density of lactating cows from 100 percent to 150 percent.

Results

Based on our inputs, and with a stocking density of 100 percent, some key results per milking stall per year were as follows: $5,307 milk sales, $442 cull sales, $167 calf value, $845 heifer enter cost, $2,973 feed cost and $867 variable other costs. Fixed costs were $730, and profit was therefore $500. Further, annual milk yield was 26,001 pounds, with a daily milk yield per lactating cow of 71 pounds; pregnancy rate was 19 percent, and annual cull rate was 37 percent.

The sensitivity analysis revealed that the optimum stocking density was very sensitive to reasonable changes in the size of the milk loss and prices.

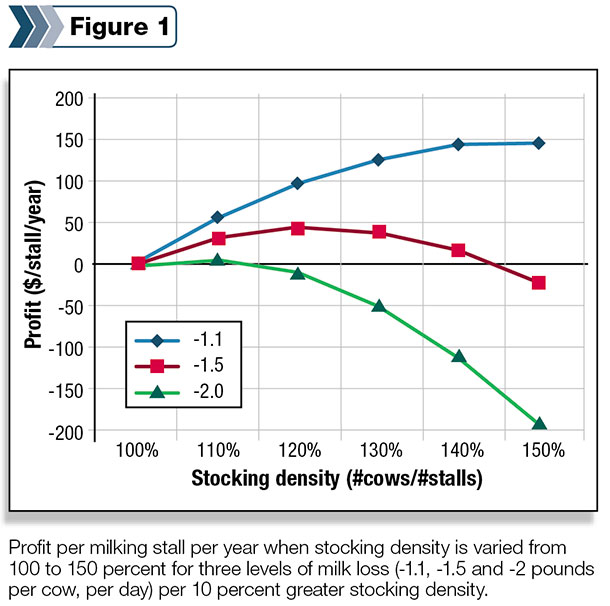

As shown in Figure 1, the effects of milk losses of 1.1, 1.5 and 2 pounds per cow per day on gain in profitability for each 10 percent greater number of cows per stall. The figure shows the level of milk loss has a large effect on the optimal stocking density and the gain in profitability.

At a loss of 1.1 pounds per cow per day, the maximum profit per milking stall is at a stocking density greater than 150 percent. The profit per milking stall per year at 150 percent stocking density is $145 greater than at a 100 percent stocking density.

At a loss of 1.5 pounds per cow per day, the optimum stocking density is at 122 percent, and the profit per milking stall per year is $43 greater than at 100 percent stocking density. At a loss of 2 pounds per cow per stall, the optimum stocking density is at 107 percent, and the profit per milking stall per year is only $6 greater than at a 100 percent stocking density. Annual milk production per stall increased in all three cases to more than 33,069 pounds per year with stocking density at 150 percent.

We varied milk prices from $0.18 per pound of milk to $0.22 per pound – $0.20 was the default. We used a milk loss of $0.32 per pound per cow per day. Higher milk prices increase the profitability of each additional cow and, therefore, encourage a greater stocking density.

With a $0.22 per pound milk price, the optimal stocking density was around 140 percent with a gain in profit of $180 per stall per year compared to 100 percent stocking density. The lower milk price of $0.18 reduced the optimal stocking density to 100 percent. At this milk price, overstocking was not profitable.

This scenario shows less overstocking is economically better when milk prices are decreased or feed costs are increased. Farmers tend to overstock pens when milk income over feed cost is reduced, perhaps to maintain cash flow from milk sales. If more costs become variable instead of fixed, then the optimal stocking density will decrease.

Better reproduction through a higher 21-day service rate (estrus detection rate) increased the optimal stocking density, but the effect is not as strong as changes in prices. The optimal stocking density increased from 118 percent at a 34 percent 21-day service rate to 128 percent at a 61 percent 21-day service rate. Profitability increased by $25 to $55 per stall compared to 100 percent stocking density.

From the limited scenarios shown, it is clear that the economically optimal stocking density is very sensitive to reasonable ranges in prices that affect the revenues and costs that vary with the number of cows. On the other hand, the marginal value around the optimal stocking density is very low (a flat curve around the optimum, see Figure 1), which means that profitability per stall is not reduced much when the optimal stocking density is reduced by 10 percent or 20 percent.

Summary

Though economic analyses of stocking density are hampered by a lack of good performance data, we concluded some overstocking is profitable under plausible economic conditions in the U.S. Situations where no overstocking or much overstocking are the most profitable are also easily found. The economically optimum amount of overstocking is quite sensitive to levels of milk and feed prices.

Stocking density should be reduced when milk sales minus feed cost per cow decreases (low milk prices, high feed prices) to maximize profitability per stall. Welfare is reduced above approximately 20 percent overstocking. There will be a trade-off between profitability and welfare in some situations. PD

Haile Dechassa is with the University of Florida Department of Animal Sciences and the Chairgroup Business Economics at Wageningen University in The Netherlands. Henk Hogeveen is with the Chairgroup Business Economics at Wageningen University in The Netherlands.

References omitted due to space but are available upon request. Click here to email an editor.

-

Albert De Vries

- Department of Animal Sciences

- University of Florida

- Email Albert De Vries