That’s exactly the approach Randy Gormley took when he left the bean business to return to the family farm.

With his son, Erik Gormley, they looked around to find what was needed, what was wanted and what it was other farmers wouldn’t do. In Burlington, Wyoming, on the RG Ranch, the answer to those questions was “small square bales.”

The hay trend of the last several years in Burlington, as in many parts of the West, has been toward large square bales. They’re faster to put up and take less manpower.

But in 2000, the Gormleys looked for a marketing angle, and they found it in small square bales shipped to Florida for the horse hay market. They produce pure alfalfa, orchardgrass-alfalfa and brome-alfalfa hay in small square bales and some 3-by-3 bales.

“This is our signature, right there,” Erik says as he suspends a flake of hay in one hand, “a flake that hangs together when you pick it up. That’s what the horse customers want.” So that’s what Gormleys provide. Erik says, “Our focus is on quality hay, plus service.”

Quality hay

Wyoming’s high-desert climate lends well to dry hay production, which is Wyoming’s number one crop. Two things have improved the Gormleys’ hay in recent years, Randy says – hand probing for hay moisture during baling and GPS steering in swathers and plowing tractors.

While not typically pinpointed as quality adjustments, Randy explains that the on-baler moisture probes weren’t ideal. “We had some moisture sensors on the balers initially, but we took those off. It made us lazy – including me – and we trusted them too far.”

Their process now is to get out of the tractor cab every 20 to 30 minutes to probe the hay and check the equipment. “It gives us a better feel for conditions,” Randy says.

The Gormleys have also used an inoculant for the last few decades on every bale of hay produced. Small bales are baled at 18 percent moisture, and 3-by-4 bales are baled at 16 to 17 percent moisture. They have tried gradually converting their horse hay customers to larger bales with modest success, increasing the supply and selling more every year.

Keeping the bales covered is also a priority. Neighbors thought Gormleys were crazy when they built the 60-foot-by-500-foot hay barn, because nobody was building hay barns with that configuration.

But they built it anyway. With their marketing focus, it made sense for them to be able to access any type of hay from any field, from any cutting that a customer might want, instead of having to say, “Well, I can’t sell you that hay until I sell the hay stored in front of it.”

That was part of the customer service they wanted to offer – an inventory list with the capability of loading out any hay on the list at a moment’s notice. Each of the 20 bays in the barn holds 2,000 small bales. They designed and constructed the barn themselves, buying the steel beams and purlins from a dairy barn that was being sold. Erik says, “It’s built for marketing, not for looks.”

Randy also credits GPS steering to making a huge difference in hay quality, making it more uniform. Typically, baling hay in Wyoming starts about 2 a.m. and quits at 5 or 6 a.m., then starts again about 9 a.m. when the dew burns off.

With GPS steering, the windrow width is exactly right, so no slugs are created that a baler can run into during the night while baling in the dark. In addition, the operator can watch the machinery and the windrow feed without steering.

Randy says it’s also important for the plow tractor to have GPS steering because no matter how many times a field is rolled, disked or leveled after using a mouldboard plow, the plow blade still creates the deepest furrow, and water will follow the plow furrow, creating uneven growth.

Customer service

Customer service can mean different things to different businesses. For the Gormleys, an important aspect of customer service means extensive recordkeeping and providing regular updates to customers.

Erik says, “Dad had a business background in his bean career, and he brought those business applications into the farm operation.” The first business practice he brought, as mentioned, was to focus on identifying specific market opportunities.

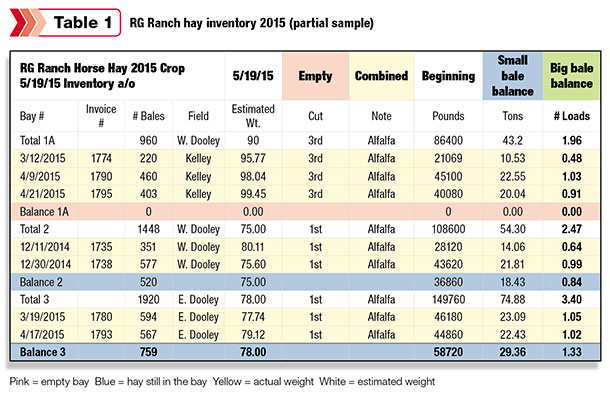

The second business application involved recordkeeping – every field, every cut, every bale, every estimated weight, every forage quality test, every stacker load, every bay inventory and every semi-load.

This information is tracked in an Excel spreadsheet, and after every customer buys a load of hay, the customer receives these reports: bill of lading, invoice, current inventory report (available hay for sale by type and quantity, bale size and weight) and an aging accounts report.

Trucks are “scaled in and scaled out” to provide accurate weights, and Erik says the customers appreciate the reports. While it’s a lot of attachments in an email, customers know exactly what hay is available to buy and what is owed on their account.

To track that information, Gormleys use Excel, Adobe (for scanned documents) and QuickBooks. They tried other software programs but found they could build the spreadsheets to do exactly what they wanted. While it takes data-input time, Erik says, “Without the paperwork side, we wouldn’t be where we are today.”

Options

But everybody knows, rain happens – so every hay operation has to have a contingency plan. Erik says, “In the hay business, you have to have cows,” and that’s their contingency plan.

The Gormleys carry 1,000 cows and a commercial herd on two ranches (two units located in Casper and the rest run in Burlington) with 300 heifers and 300 heiferettes.

The cattle are fed whatever hay is rained on or otherwise lower in quality. “If hay has a blemish in the bale, we don’t mess with it. We pull it out of the stack and set it aside for the cows. We have to be picky because our customers are picky,” Erik says.

RG Ranch also uses corn as a rotation crop but not necessarily in the traditional way – it’s not silage, and it’s not dry grain corn. Instead, they bought a corn picker because they hated to see the cob wasted.

Now they pick the corn at 16 to 18 percent moisture, bunker it, graze the cornstalks and feed the whole corn (including cob) to cows in the winter. Randy says feeding the pit corn in the winter has improved cow body condition for breeding and has decreased their open rate.

Meeting this need in the horse hay market means RG Ranch is shipping hay year-round, which helps even out cash flows. Erik points out that with just a cow operation, you receive only one or two checks a year, but the year-round hay income has eliminated the need for an operating loan, which also saves interest cost.

Erik represents the fifth generation of Gormleys on the ranch. His great-grandfather came to the Big Horn Basin in 1894 with sheep, building a concrete-base barn in 1915 and hand-digging a well 20 feet deep which still flows. Erik’s grandfather, Richard Gormley, quit haying in the ’60s and rented the farm out, then later returned to hobby farm.

Randy spent 20 successful years in the bean business before returning to the farm. Now Randy and Erik produce hay full-time on the family farm, coming full circle with their family roots. FG

Go to www.progressiveforage.com/wyoming-hay to watch a video on hay production in Wyoming.

PHOTO 1: Erik Gormley explains his hay inventory system to Wyoming Business Council Forage Program Manager Donn Randall.

PHOTO 2: Richard Gormley entered the Big Horn Basin in 1894, built the barn in 1915 and established a legacy of hard work, faith and family.

PHOTO 3: Premium horse hay is loaded for shipping to Florida’s horse-hay market. Photos courtesy of Lynn Jaynes.