It’s human nature to love puzzles. We naturally want to feel ingenious by piecing each misshapen token together to create something bigger and better.

On robotic dairies, there are many puzzle pieces which must come together to achieve peak herd performance, with data being an essential piece providing insight into opportunities for improvement. However, it is easy to become overwhelmed by all the data available, data which is time-consuming to analyze and act on. Simplifying the metrics used daily to analyze performance is an excellent way to leverage herd information for decision-making.

Key performance indicators (KPI) are the specific metrics evaluated daily to provide a snapshot of the herd. These may include the average number of milkings per day, the average time spent in the robot per milking and/or the average feed consumed daily per cow at the robot. Another essential KPI on robotic dairies is feed allotment. Are your cows consuming the entirety of the robotic feed allotted to them without being cut short and risking milk production losses? We can help you answer just that.

Economic risks of falling short

While offering the cow the robot feed she needs is important throughout her entire lactation, it is especially crucial during her fresh and peak milk production periods, as these periods impact persistency, health and, most importantly, milk revenue. To evaluate our Feed Allotment KPI, we need to start by evaluating if individual cows are able to consume the feed they are allocated in the feed table, paying special attention to cows not meeting production expectations.

When looking at feed tables specifically designed for the fresh group, the “chase the pellet” concept is important. “Chase the pellet,” in other words, ensures that feed allowance increases to support energy demand prior to increased milk output. In typical feed tables, the robot feed allowance increases following the surge of milk production. By having the feed available to the cow as her lactation curve accelerates, she is essentially “chasing the pellet.” Reviewing fresh cow protocols including fetching, hoof health and environment can certainly help cows falling short of their feed allocation and, in turn, decrease the risk of metabolic disease. The “chasing the pellet” concept can especially help decrease the risks of ketosis, as this is tied closely with energy intake.

Using key performance indicators to complete the puzzle

Let’s identify the KPIs needed to calculate feed consumed versus feed table allowance. Looking beyond the average with the indicators (number of milkings per visits per day, box or milking time, feed dispensing rate and maximum feeding rate per visit) will allow you to identify precisely how much feed cows are consuming.

1. Number of milkings or visits

Whether “milkings” or “visits” is the preferred terminology for your farm, the definition for the purpose of this article is the number of times a cow is milked per day which, on average, is 2.7 to 3.1 times each day.

2. Box time

Box time refers to the time the cow is in the robot to get milked, which is on average approximately six minutes and 30 seconds.

3. Feed dispensing rate

The feed dispensing rate is the distribution of feed per minute at the robot and generally is approximately 0.75 to 1 pound per minute. The density and the quality of the pellet influences the average at which this is set. It is important to note that a cow’s average eating speed is influenced by her muzzle width and ranges from 0.75 to 1 pound per minute, which should be aligned with the dispensing rate.

4. Feed per visit

A cow’s maximum feed per visit usually varies from 5.5 to 7.7 pounds but may be lower depending on the robot barn design (for example, free-flow versus milk-first barn designs). As a reminder, the pellet offered to the herd must be palatable and have a proper energy difference with the partial mixed ration (PMR). Note that herds with homogenized pens by days in milk (DIM) may prefer to alter the PMR and choose narrow ranges of robot pellet distribution to create flow in their barn.

What’s next?

Generally, the milkings/visits per day and box time are displayed on the robotic milking main software screen. Finding the feed dispensing rate and total feed per visit may require more investigating. But once these KPIs are known, a quick calculation will complete the puzzle and reveal whether your herd is indeed “chasing the pellet.”

Chasing the pellet

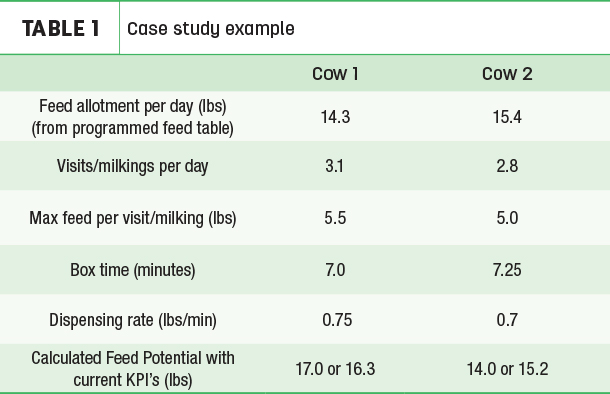

The calculations in Table 1 are most relevant in a free-flow robotic system.

Cow 1

Cow 1 has 14.3 pounds assigned to her in her feed table. She is currently visiting the robot an average of 3.1 times per day, and her maximum feeding rate per visit is 5.5 pounds, which means that she could get a total of 17 pounds per day. Her current allotment of 14.3 pounds per day easily fits within the 17 pounds potential amount calculated in this way.

If we now calculate the potential total feed using the dispensing rate of 0.75 pound per minute, and that Cow 1 is in the robot being milked for on average seven minutes, she could eat 5.25 pounds per visit. As she is visiting on average 3.1 times per day, she could get a total of 16.3 pounds, which is still well above the actual feed table assignment of 14.3 pounds. Therefore, Cow 1 can reach her ration requirements and “chase the pellet” if the feed table is built accordingly.

Cow 2

Cow 2 has 15.4 pounds assigned to her in her feed table. She is currently being milked an average of 2.8 times per day, and her maximum feeding per visit is 5 pounds, which means that she could receive a total of 14 pounds per day. Her current allotment of 15.4 pounds per day will not be met and will be limited to 14 pounds with this calculation.

If we now calculate the potential feed total using the dispensing rate of 0.75 pound per minute and that Cow 2 is in the robot being milked for on average 7.25 minutes (seven minutes and 15 seconds), she could eat 5.44 pounds per visit. As she is visiting on average 2.8 times per day, she could get a total of 15.2 pounds, which is still below the targeted 15.4 pounds.

Therefore, Cow 2 cannot reach her programmed ration in the feed table and would be limited to the lower calculated value of 14 pounds per day. The impact of this limitation could increase the risk of metabolic disease in the fresh period and negatively affect reproduction, milk production, peak milk potential and overall persistency in her lactation.

The examples above explain just how important KPIs are to evaluating feed allotment and validating the “chase the pellet” concept. Setting a feed table is one thing; validating feed intake at the robot is quite another – and this can be done simply and easily, leading to significant performance returns. Defining your management KPIs is key, as these serve as puzzle pieces to leverage your herd data, allowing you to drive profitable decisions and success.