For as long as we have milked cows, we have been challenged by mastitis. Despite decades of advancements in science and technology, mastitis remains a very complex disease.

Combating and managing this disease can be quite overwhelming at times. Following the National Mastitis Council’s 10-point mastitis control program is sound guidance for finding resolutions. Proper maintenance and use of milking equipment is only one part of this plan, but do not overlook it. Your milking equipment is one of many factors that must be investigated and eliminated as a potential cause of mastitis.

The connection between mastitis and milking equipment occurs at the teat end with the introduction of bacteria into a quarter during milking. This bacterial introduction can occur due to equipment malfunction or by incorrect procedures or milking settings. To determine where deficiencies are within your system, there are a few areas you can focus on to isolate potential mastitis drivers.

Preventative maintenance and testing

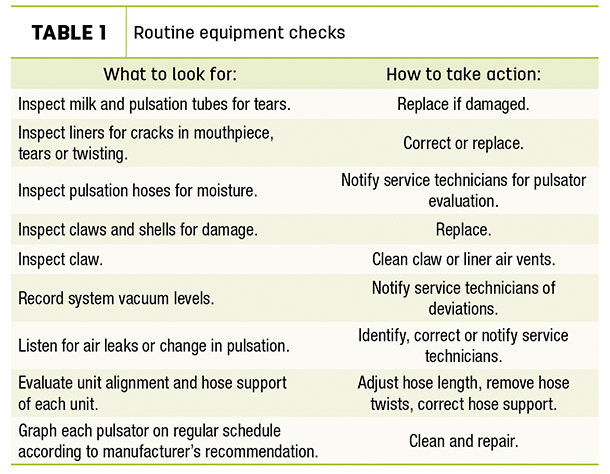

We are all familiar with the Ben Franklin quote, “An ounce of prevention is worth a pound of cure.” This is a vital piece of advice when it comes to milking equipment. First, you should work with your technical service provider and equipment dealership to ensure preventative maintenance is performed on a routine basis. How often this should be performed will depend upon the specific type of milking equipment you have and your particular component needs. It is important your scheduled maintenance includes not only replacement intervals but inspection of components as well. Inspecting components will reveal early wear, which may be a sign of larger problems within your system (see Table 1).

Second, developing and ensuring employees complete basic inspections every day or at the start of every milking will ensure problems are caught early before they develop into larger issues. Simple tasks such as checking hoses or liners for cracks or tears, inspecting pulsation hoses for moisture, clearing plugged air vents, recording system vacuum levels and listening for irregular sounds (an air leak or change in pulsation) will result in early detection of problems and possible prevention of new mastitis cases.

Finally, if you have a significant or sudden increase in somatic cell count (SCC) or clinical mastitis rates, it never hurts to have your system fully evaluated with a dynamic test to ensure vacuum and pulsation are within desired parameters while milking. This dynamic test would include a long vacuum recording (up to 30 minutes) at the receiver to determine if there is significant system vacuum fluctuation during milking. It would also include several claw vacuum recordings that will reveal if there is too much vacuum fluctuation in the claw.

Unit alignment

One crucial step of the milking procedure that many dairies overlook is unit alignment. Incorrect unit alignment can lead to uneven milkouts and a longer milking duration, which influences teat-end health and encourages liner slips. All of these scenarios increase the risk of mastitis. Proper unit alignment is achieved through a balance of udder conformation, hose weight, hose length, hose support and correct attachment. Achieving unit alignment may be as simple as a reduction in hose length or installation of better hose support mechanisms. While hose support with parallel milking tends to be more challenging, it is possible.

Liner slips

Liner slips cause vacuum differentials in the milking cluster. This can lead to or increase teat impacts of milk contaminated with bacteria from the air, the liner or the outside of the teat. Occurrence of teat impacts increases the risk of a new mastitis infection. Poor udder or teat conformation, improper unit alignment, improper liner selection for your herd’s teat size and/or improper installation and settings for your liner lead to liner slips. Liners are not all the same. Each liner is designed to fit a particular range of teat sizes. Each liner has a recommended vacuum and pulsation operating range. When you are choosing a new liner, be sure your supplier sets your system for the new liner, then monitors liner fit and performance. Do not accept liner slips as normal. In general, if you have more than 10 liner slips for every 100 cows, you should investigate why and determine what solutions are available.

Evaluate teat condition

A final judgment of how your milking equipment is or is not influencing mastitis within your herd can be determined by scoring teat ends and teat condition after milking cluster removal. For a true evaluation, you will need a representative sample of the entire herd (including cows from all groups, DIM, parity and production ranges).

Short-term changes in teat condition are generally in response to a single milking. These changes include discoloration (reddened, bluish or purple-colored teats), firmness or swelling of the teat, “ringing” around the upper teat barrel or wedging of the teat end. Short-term changes can increase inflammation, decrease milkouts and influence cow behavior during milking. It may take several hours for a teat to fully recover its integrity. If short-term changes are of concern, investigations should focus on high milking vacuum, faulty or incorrect pulsation (too short or too long D-phase), liner selection (wide-bore, high-tension liners, large mouthpiece chamber or stiff mouthpiece lip) and overmilking.

Hyperkeratosis is excessive keratin growth and is caused by a combination of teat shape, environmental factors, milking management issues and milking machine faults. It is a medium to long-term change in teat condition typically occurring over a period of two to eight weeks. Teats with hyperkeratosis will harbor more bacteria and are very difficult for milkers to clean properly, increasing the risk of mastitis. If your herd exhibits significant levels of hyperkeratosis, specific machine factors to investigate include the length of the D-phase in pulsation, total unit on-time, time spent in low flow at the beginning of milking (bi-modal milk flow due to improper stimulation or not enough lag time before attachment) and automatic take-off settings.

Milking clean, well-stimulated cows with correctly functioning, well-maintained milking equipment operated as recommended by the manufacturer is unlikely to cause mastitis. Routine inspection and evaluation of teat condition, liner interaction with your cows, the milking process and your milking equipment will help preserve the udder health of your herd.