As we continue to improve on-farm efficiencies, it’s important to look at new areas of opportunities. One area needing review is manure management, specifically the process of converting manure solids, separated or not, into safe, high-quality bedding.

For many years, inorganic bedding, specifically sand, was the gold standard material used in deep-bedding systems, as it provided a hygienic starting material that contained almost no pathogens. Unfortunately, this premium bedding has become expensive and more difficult to acquire due to competition with other industries and limited supply. This has forced producers to look at alternatives to backfill the need. Manure became a viable option to replace sand and other inorganic bedding for the simple fact that most farms have more manure than they need (or are allowed) to apply to cropland, and it carries little to no cost. While it can be used very successfully as bedding, it also poses challenges, specifically how to handle manure to reduce or eliminate pathogen loads.

The use of dairy manure solids as bedding was established in the early 1970s, particularly in arid environments in the U.S., to decrease bedding cost and manage increasing quantities of manure from larger confinement rearing systems. Recently termed “green compost,” it consists of the solid fraction of manure separated from the liquid fraction with minimal composting. This product can contain high bacteria loads and, if not managed properly, can heat up in the beds and pose a particular challenge to producers. Due to these concerns, processing steps were incorporated to help increase the dry matter of the separated material. One step was the addition of high-performance slurry-separation machines that increased the dry matter of the separated solids from approximately 15% up to 30%, which assisted in reducing pathogen prevalence and growth. Even at the higher dry matter, the risk of excessive pathogen load still existed, so the incorporation of a composting step helped to further reduce this load.

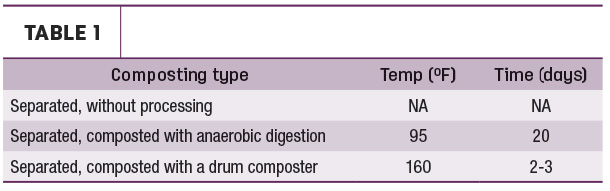

One method for producing composted manure solids for bedding is using separated solids from anaerobic digesters. Anaerobic digestion is the process where manure and other organic materials are broken down and converted to biogas, specifically methane and carbon dioxide, which then can be sold and used to generate power. Anaerobic digestion takes place at 95°F for 20 days or longer, effectively killing nearly all pathogens in the process (Table 1). The digestate can be separated and then used as composted bedding.

Another process of making quality dry manure solids is the use of a drum composter. This process consists of taking separated manure solids and placing them in a drum composter, which accelerates the composting process by drawing oxygen through the separated material. The introduction of oxygen creates a higher-temperature environment, approximately 160°F, which effectively kills most pathogens in approximately three days (Table 1). These methods in addition to other combinations of separation, digestion and composting have opened more areas of the U.S. to the benefits of producing safe, dry manure solids for bedding. Even with these improved methods to reduce pathogen load, management of the bedding has a significant impact on the quality and cleanliness of the end product.

Many pathogens can be found in wet manure, including bacteria, protozoa and viruses, that can pose an increased risk of infection if still present in the bedding. Escherichia coli (which can be shed in the manure between 3-50,000 colony-forming units per gram (cfu/g)), klebsiella, environmental streptococci, salmonella (which can be shed in the manure between 20-50,000 cfu/g), Mycobacterium avium subspecies paratuberculosis (the root organism in Johne’s disease), cryptosporidium and listeria are just a few organisms that if left unchecked could wreak havoc on the health of your animals. Survival of these organisms during the composting of manure is dependent on a variety of factors including pH, dry matter, temperature and starting pathogen load, all of which can be impacted by a variety of conditions linked to storage and management, including sunlight, drying time, exposure to oxygen and ammonia concentration.

If proper management practices are not followed in the composting and handling process, serious negative health outcomes could persist. One significant impact is udder health, specifically mastitis and somatic cell counts. Although there isn’t a direct link between the use of well-managed dried manure solids as bedding and a decline in udder health, if dried manure solids are mismanaged or strict digestion and composting protocols aren’t followed, bacteria, specifically E. coli and klebsiella, can thrive in this environment and pose a significant risk. Udder health isn’t the only area of concern when discussing potential impacts on cow health from improperly handled dry manure solids bedding.

If salmonella isn’t completely removed from dried manure solids, it can be ingested and lead to additional cases of salmonellosis. Salmonella can be spread through fecal-oral transmission, aerosol transmission, saliva and nasal secretions, as well and through milk. Salmonella infections can cause lethargy, dehydration, diarrhea and losses in milk production. Although supportive treatments like fluids and nonsteroidal anti-inflammatory drugs can be used along with the preventative support of a science-based, research-proven probiotic, it is imperative that we work diligently to manage and maintain our bedding to minimize the risk. No matter which process may be used to convert separated manure solids into dry manure solids, it is imperative to periodically review the process and management procedure for handling and storage to ensure consistent availability of safe, pathogen-free bedding.

References omitted but are available upon request by sending an email to the editor.