Ensuring forage quality and nutritional value over the long winter months is a yearlong process. The minute forage is cut, it begins to lose nutritional value. There is no way to increase quality from this moment on. However, making smart choices throughout the haying cycle can help preserve quality and nutritional value. In our previous article, we discussed steps to take during mowing and conditioning. Here, we will look at steps hay producers can take during the baling, storage and feeding process to maximize their forage value.

Tips for better baling

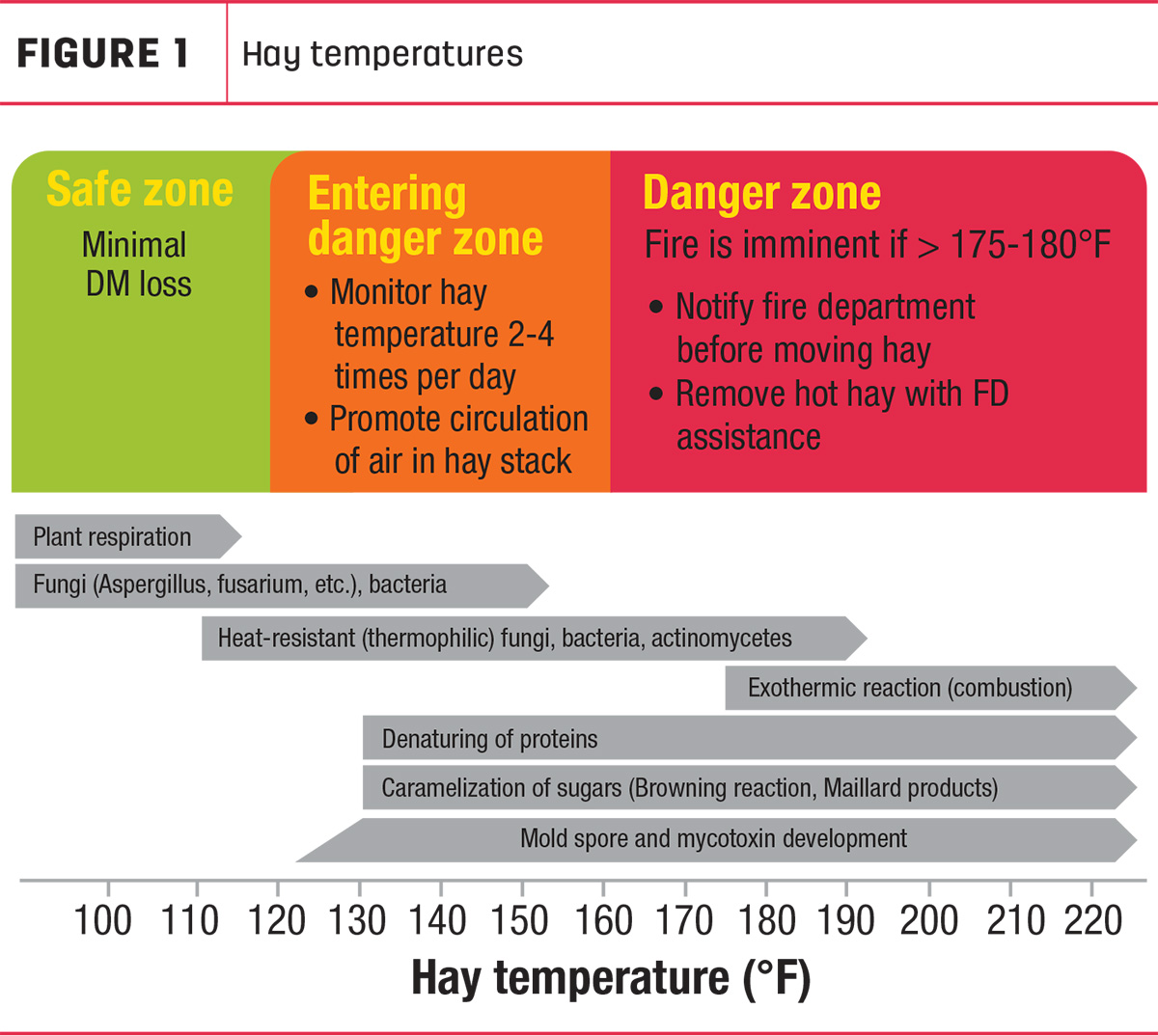

Our earlier article touched on the importance of forage moisture levels, but this vital factor bears repeating. Maintaining ideal moisture during the baling process is key to ensuring long-term forage quality. Producers risk leaf shatter when baling forage that is too dry. Too moist, and forage can suffer denaturing of proteins, caramelizing of sugars and development of mold and mycotoxin (Figure 1).

With short working windows, it’s not always possible to bale at ideal moisture. In these situations, hay producers can apply preservatives to help maintain quality and nutritional value when used correctly. These compounds are applied through spray application as forage enters the baler or granular across the top of the bale. Using organic acids and their salts, sulfur-based preservatives, ammonia-based preservatives and bacterial inoculants allow for safe baling at higher moisture levels – up to 25% moisture in some cases. Preservatives can also speed up drydown when applied during mowing, potentially enabling producers to bale sooner. Treated hay also retains its color, making it more appealing to hay buyers and livestock alike.

Selecting the right compound for each specific situation is important for optimal results.

Organic acids

Applying an acidic preservative, such as propionate or acetate, creates a hostile environment for mold, yeast and bacterial growth. These acids are naturally occurring in the rumen and cecum and therefore are safe for all types of livestock. Less caustic “buffered” acids are safer to handle and less corrosive to machinery. These might also be labeled “neutralized” or “pH balanced.” A common buffered acid is ammonium propionate.

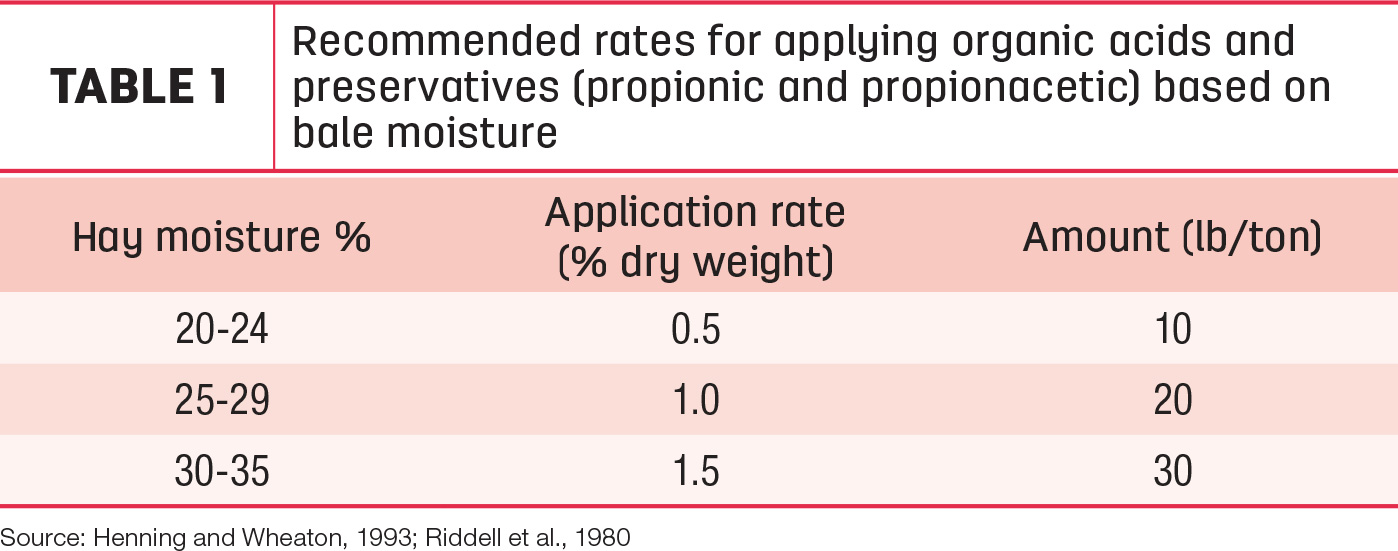

Application rate varies based on moisture level and acid type. Preservatives with higher percentages of propionate will be more effective. Be sure to calculate the specific acid weight, rather than overall product weight, since this can result in less effective preservation. Propionic acid is especially effective against mold, while acetic acid works better against yeast and bacteria, making a blended mix an ideal choice in many situations (Table 1).

Sulfur-based preservatives

Sulfur-based preservatives have long been used in animal and human food sectors. This family of compounds removes oxygen, starving microbes such as mold or yeast. Sulfur-based preservatives have a lower application rate than organic acids, making them a more cost-effective choice. These products are also more user-friendly since they are not acidic.

Ammonia-based preservatives

In some situations, anhydrous ammonia can prove to be an effective preservative. It works best for grasses and should be avoided with alfalfa forage since it can form toxic chemicals in the hay. Bales must be wrapped individually or stacked, then covered and sealed in plastic. An airtight seal is important. Application rates vary from 20 to 40 pounds per ton depending on moisture, but ammonia-based preservatives have proven effective up to 35% moisture.

At higher rates, 2% to 4% dry matter basis ammonia-based preservatives can improve feeding value in some forages, such as cereal straw, mature grass and corn stover.

Bacterial inoculants

This preservative technique adds more “good” bacteria to improve aerobic stability, usually through the production of lactic acid. These bacteria are naturally occurring in forage, but adding a little extra helps prevent mold and yeast growth. It can also help preserve hay’s green color. Common lactic acid-producing bacteria include lactobacillus, pediococcus, streptococcus and bacillus. Inoculants work best at 25% moisture and below. Bacterial inoculants protect against moisture changes in the 3% to 5% range. Bacterial inoculants are also effective in ensuring proper fermentation in high-moisture silage by introducing more desirable bacteria to favor the production of lactic acid – the most ideal acid in silage production.

Proper storage techniques

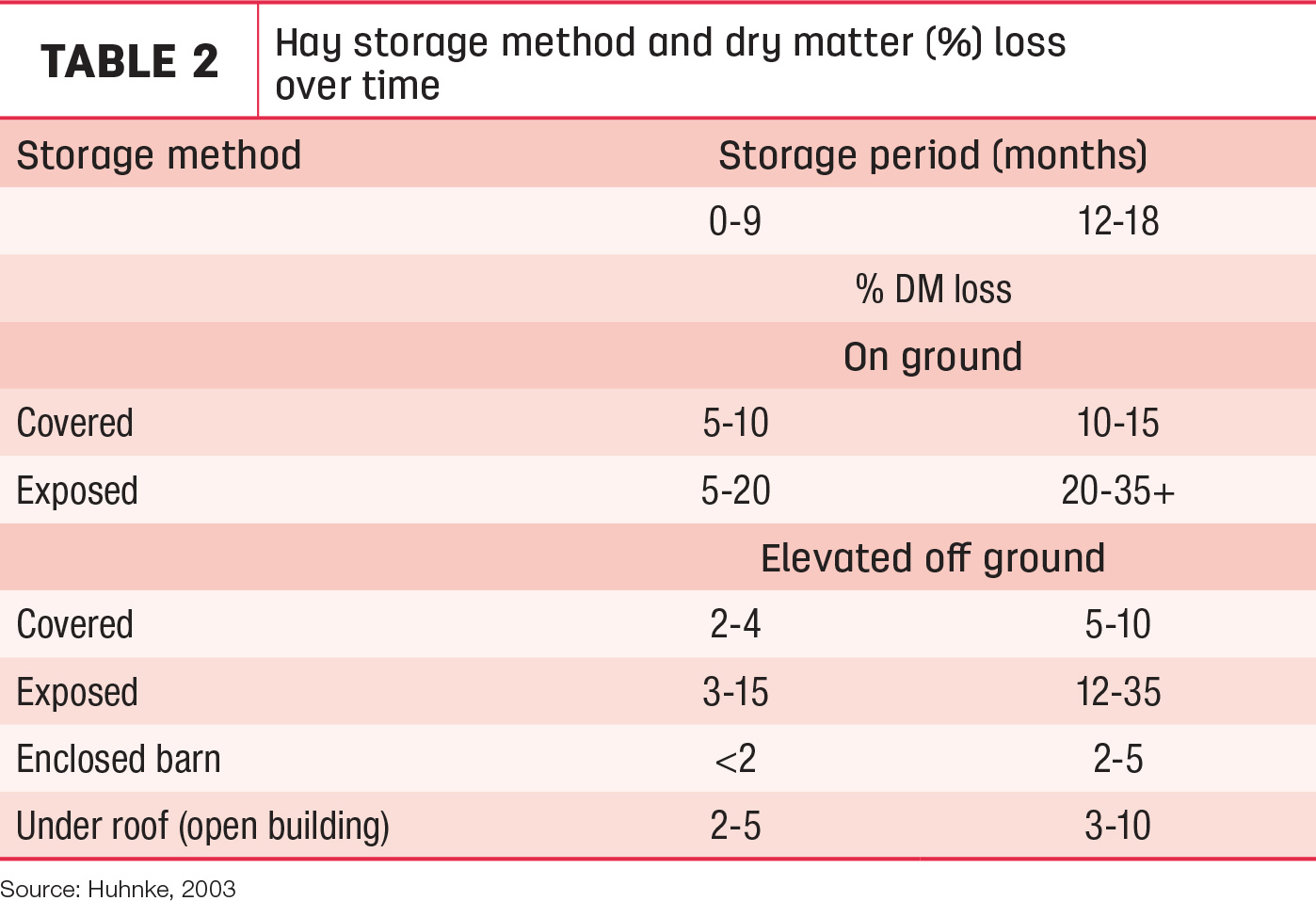

Poor storage conditions can lead to significant dry matter losses – more than 35% in some cases. This can have a big impact on a livestock operation’s bottom line.

Indoor storage space is the best defense against quality and nutritional losses due to weathering. Bales stored in an enclosed barn have much lower rates of dry matter loss, and there is very little to no nutrient loss from leaching. This is the removal of nutrients as rainwater passes over and through the bale. Leaching has a bigger effect on the more digestible nutrients, since these nutrients are more soluble. Hay stored in an open building will have slightly higher losses but still relatively low compared to outdoor storage (Table 2).

However, storing hay indoors or under a roof is not an option for all producers. To limit dry matter and nutritional loss when storing hay outside, follow these recommendations.

• Store bales on a dry, flat surface where standing water and weeds will not be a problem. If site preparation is an option, creating a concrete or stone pad allows for excellent drainage as well as supporting tractors and other heavy equipment.

- Choose a storage site away from buildings or trees to minimize shade.

- Stack bales end to end. Weathering, or the effects of climatic conditions on hay, primarily affects hay in the outside circumference of a round bale rather than the end. Additionally, reducing hay bale circumference can provide some dry matter preservation gains.

- Leave ample space between rows to promote air circulation. This will help keep hay dry to reduce leaching and moisture damage.