Cows have roamed the earth for thousands of years, their origins dating back to the Ice Age. So it is no surprise they prefer cooler temperatures – their ideal temperature range is 40ºF to 60°F. Rising temperatures in summer months are challenging for highly productive cows, and this is exacerbated if feed is unstable, heating and spoiling during feeding.

Not only do hot cows hate hot feed, but hot feed is spoiling, becoming increasingly contaminated with “bad actor” microbes, which ultimately depresses intake, performance and profitability. It is crucial to understand the risks associated with unstable heating feed and take appropriate steps to minimize issues to maximize cattle health and profitability.

The root of the problem

Although many think mold is the biggest concern when it comes to feed spoilage, the root cause is the wild yeast population, which becomes a greater concern when temperatures remain consistently above 60ºF, especially in humid conditions. Wild yeasts are invisible to the naked eye, but they are all around us and grow in crops in the field. Successful well-managed ensiling helps keep wild yeast under control, but when silage is opened to the air, they can multiply rapidly.

Dr. Limin Kung Jr. of the University of Delaware observed that producers often have problems when the numbers of yeasts are more than 106 (1 million) per gram of silage. He found that under optimum conditions, yeasts can double in number in about two hours, so a corn silage starting with 100,000 yeasts per gram could contain over 400 million yeasts per gram after 24 hours.

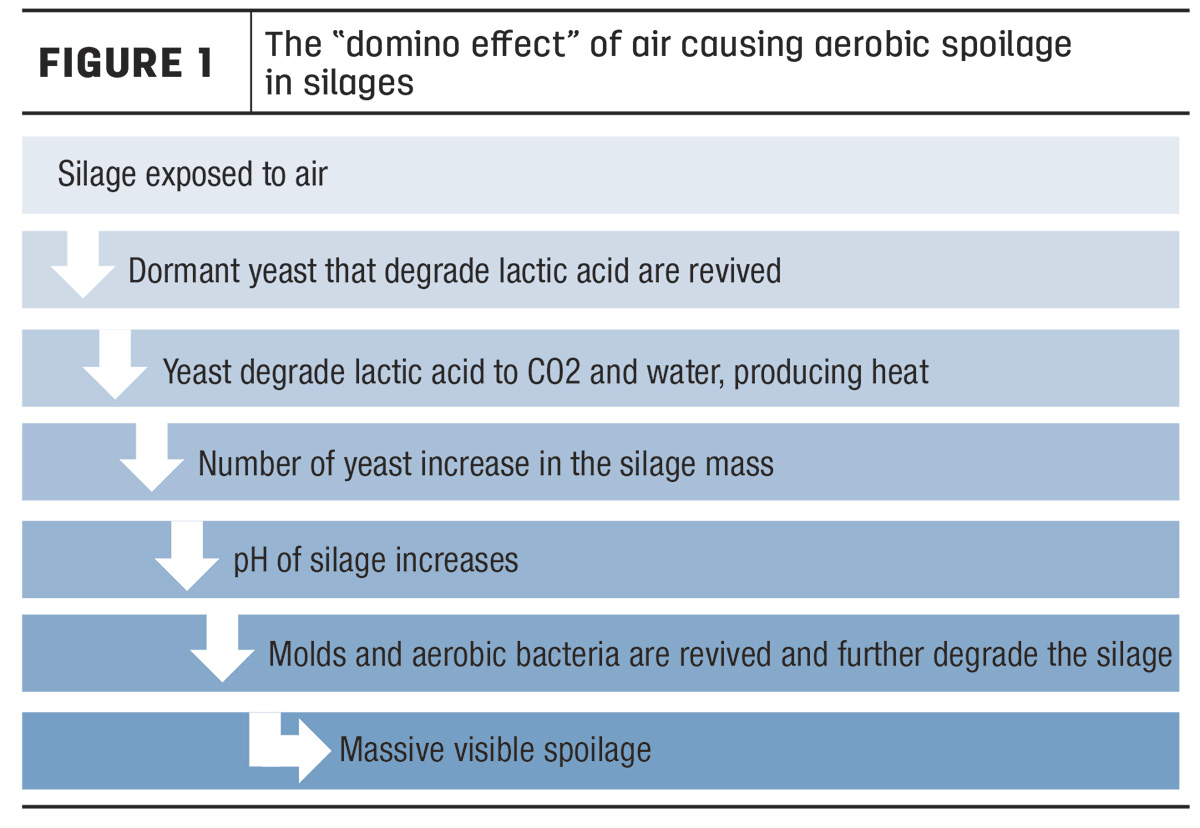

Kung has described the yeast issue as a domino effect (Figure 1). When the silage is exposed to aerobic conditions, the yeasts "wake up" and feed on sugars and lactic acid. This leads to an increase in yeast numbers and the loss of highly digestible nutrients, thus producing heat and increasing the pH of the silage due to lactic acid utilization. This then allows molds and bacteria to grow, causing further spoilage, heating and pH instability.

The impact on production

Yeasts and other microorganisms that grow during aerobic spoilage consume the most highly digestible nutrients (e.g., carbohydrates, proteins, amino acids, etc.), which results in dry matter (DM) and nutrient losses. The extent of losses depends on several factors including the starting level of yeast contamination, the initial DM content of the silage, the amount of oxygen present, the temperature and humidity of the storage environment and the presence or absence of anti-yeast compounds. Aerobic spoilage during storage is responsible for most of the DM loss, which can be as high as 30% to 40%, but even short-term exposure to air can result in significant losses. Corn silage exposed to air for just one or two days showed DM losses as high as 6%.

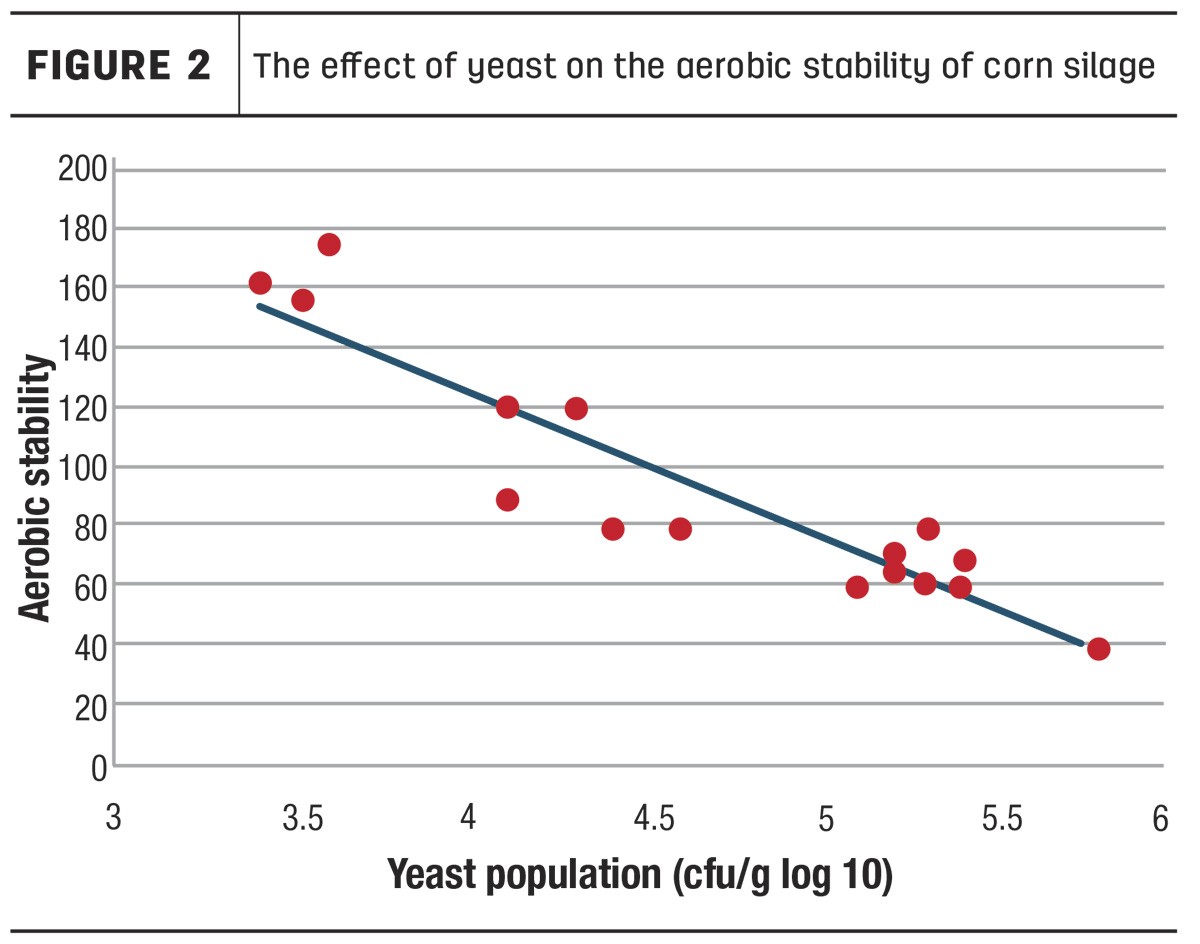

Aerobic stability is negatively correlated to yeast numbers present at silo opening (Figure 2). Corn silages with low yeast counts (about 103 cells per gram) remained cool more than three times as long as silages with high initial yeast counts (about 106 cells per gram). Less yeasts present at opening means less risk of rapid contamination, associated heating, DM and nutrient losses once the silage is exposed to air.

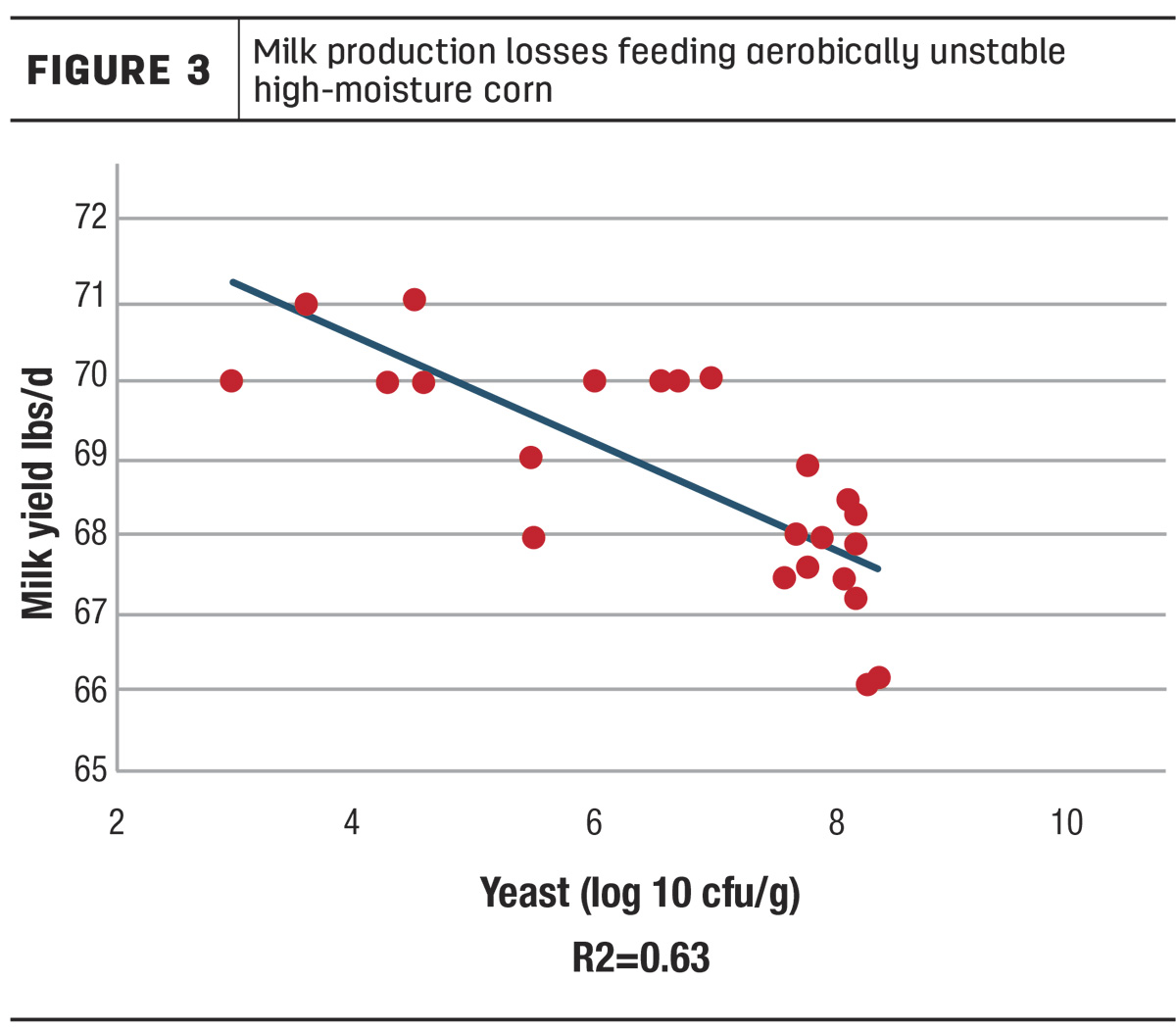

As the yeast population grows, nutrient losses in the feed increase, and intake and production by dairy cattle decrease, which reduces profitability (ROI). Milk yield steadily decreased as yeast levels increased in a 14-day supply of high-moisture corn (HMC) that was removed all at once from a silo, kept in a loose pile and fed daily to cows (Figure 3). Cows fed material removed fresh from the silo daily were unaffected. This negative effect was due only to yeast growth, no mycotoxins were involved.

Along with DM losses, contaminated silage mixed into the total mixed ration (TMR) and consumed by cattle inoculates wild yeast into the rumen, which can lead to a drop in the rumen pH. This can ultimately lead to subacute rumen acidosis, exposing cows to a range of health problems.

From a relatively simple ROI perspective, each 15°F increase in temperature in 1 ton of 30% DM silage requires more than 6.3 MCal of energy, costing around 20 pounds in lost milk production per ton of silage. Additionally, feed costs increase due to lost nutrients and DM, along with increased refusals.

What can be done

Ideally, we would prevent wild yeast growth altogether, eliminating ingestion by cows. However, this is not always a possibility. When it is too late for prevention, producers can use dilution to keep rations as clean as possible.

Dilution

Reducing the level of feed contaminated with wild yeast in the ration can mitigate the negative impacts on your herd. However, it is important to keep in mind that the addition of as little as 5% badly spoiled silage in the ration (DM basis) can decrease neutral detergent fiber digestibility (NDFD) by up to 7.2 points. Use spoiled feed sparingly to avoid losses in fat-corrected milk (FCM). If dilution is your only option, consider smaller, more frequent feedings to minimize the amount of time contaminated feed is exposed to oxygen and spoiling the ration.

Prevention

Producers can take several steps to prevent contamination and set themselves up for success. The most important thing is good silage management.

Harvesting

Prevention begins with good harvesting practices. Forage should be at its ideal maturity and moisture content when harvested – crops too wet or too dry can be prone to wild yeast colonization. The crop should be chopped and processed properly, filled quickly and packed to the correct density (minimum 45 pounds fresh weight per cubic foot) to minimize silage porosity. Avoid extended silage-making and delays in sealing. The silage should be covered, weighted and sealed to prevent exposure to air.

Inoculation

Consider using a high-quality forage inoculant with research specific to the product validating effects on aerobic stability in the silo and during feeding. The inoculant should contain the same specific strains at the same levels (cells per gram) used in the research studies. Lactobacillus buchneri applied at 400,000 cells per gram forage or 600,000 cells per gram HMC will prevent wild yeast growth and increase stability. Look for an inoculant proven to achieve fast fermentation, improve digestibility and maintain aerobic stability, to maximize the hygiene of the silage you feed. The high-level L. buchneri has been shown to increase aerobic stability of high-moisture corn and corn silage and increase the bunk life of the TMRs produced. The effectiveness of L. buchneri has been further improved by combining it with L. hilgardii, allowing for opening and feedout after only 15 days storage.

Monitoring

It is also crucial to recognize if your feed is becoming unstable and take appropriate actions. It may be obvious if the feed is grossly spoiled, based on its appearance and strong odor, or cows not wanting to eat it.

However, you should also monitor silages using temperature probes. Two probes are required, one to measure at approximately 3 feet into the pile and one for approximately 6 inches. Typically, temperatures will range from 65ºF to 90°F at 3 feet, with higher values on the shorter probe. A temperature differential greater than +10°F between the two readings is a sign of aerobic instability. When in doubt, send samples into a lab to be tested for spoilage.

Wild yeasts are everywhere, and preventing them can be challenging. However, it is crucial to understand their impact and techniques to help reduce the feed spoilage the yeasts can cause. After all, your ROI is directly impacted by the quality of the feed your cows are consuming – and hot cows hate hot feed.