I enjoy reading Tom Wall’s monthly articles on employee management in Progressive Dairyman. He brings intelligent ideas to the important topic of managing your employees. For understandable reasons, I am seeing more small dairy farms hire outside help to reduce the burnout from a 24-7, 365-day work schedule. So keeping employees happy is on the management plate of most dairy owners across the country today. But are you sure all your employees are happy?

I admit a bias, since my entire life, including a 32-year professional career, has been dedicated to keeping the “four-legged” employees happy and healthy on dairy farms. I am sure Mr. Wall will agree with me that comfortable cows and satisfied employees are a winning combination for a profitable dairy business.

In this article I want to suggest how to determine if you have comfortable, happy cows in the milking parlor.

The two “big-picture” goals for milking a cow are:

1. Attach units only to clean, dry and well-stimulated teats

2. Accomplish Goal #1 quickly and comfortably

When you drill down into the second goal, it becomes evident that quick and comfortable can at times be in conflict with each other. Economic pressure and the relentless pursuit of increased efficiency have driven the U.S. dairy industry to put more cows behind every size and shape of parlor ever built.

The constant push for a faster throughput has lured dairy owners, managers and some equipment manufacturers to explore the holy grail of faster milkout – higher vacuum levels.

Milking researchers have long established the two ways to milk a cow faster are to raise the vacuum level and/or lengthen the pulsation B-phase. Research has also identified a point of diminishing return for both of these changes. Blood congestion in the teat is the problem, and an uncomfortable, unhappy cow is the result.

As you think about your own parlor settings, you must ask yourself, “How far can I push the envelope for a faster milkout without sacrificing cow comfort and creating an entire department of unhappy employees?”

My advice is to start listening to your cows because they are talking to you all the time. Your challenge is to learn what to listen for. You must train yourself to recognize normal behavior during milking and normal physical changes that occur after milking.

Because most of you seldom get opportunities to leave your own dairy and see another’s, it is so easy for the abnormal to become normal. This is one of the advantages veterinarians have by visiting different farms within our practices.

That said, we can also fall into a routine and start walking past the abnormal on a farm, accepting it as normal. This is such human nature that you have to make a conscious effort to not miss your cows telling you that something abnormal is happening to them during milking.

The three measurements I use to “listen” to cows in a parlor are manure sleeve score, teat color and cow behavior.

Manure sleeve score

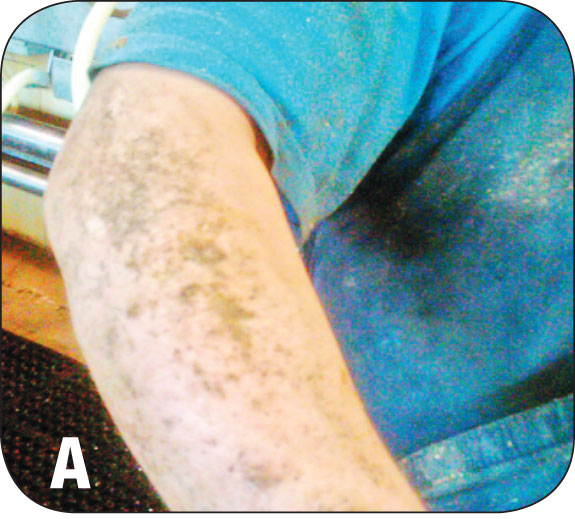

This may not be an officially researched item, but I find it very informative. I always look at the forearms of the milkers to see how much manure is on their sleeves ( Picture A ).

Obviously the length of time the milkers are into their shift affects this assessment, and heifers are typically more steppy; however, it is still very telling to watch how cows react to normal prepping procedures including fore-stripping and towel wiping.

Milkers’ arms bear the brunt of a painful prep, with manure marking the number of strikes.

Pain during prepping is not normal. Discomfort for hours after the last milking suggests chronic, deep tissue damage that has developed over time.

Research has identified that chronic overmilking and/or extremely high claw vacuum levels will lead to excessive blood congestion and deep tissue tearing, especially in the teat end, that can lead to permanent scar tissue formation and extreme pain under pressure.

So your cows may not be lying when they object to fore-stripping.

Teat color

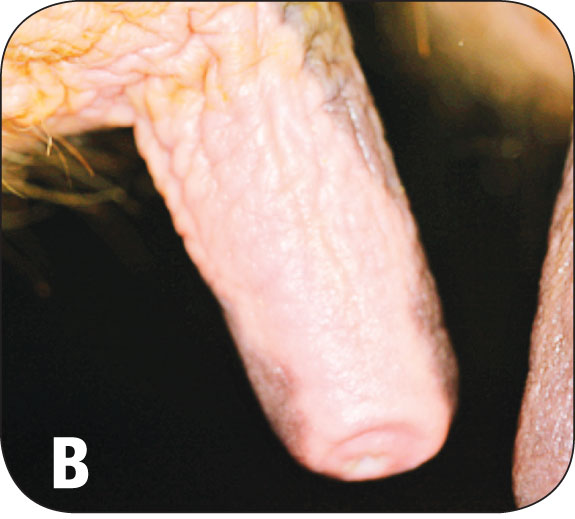

When the milker unit is removed, the skin color of non-pigmented teat skin should be pale pink to slightly red ( Picture B ).

This should fade quickly to normal, pale white teat skin color in a few minutes. A little more color in the teat end versus the barrel is not unusual.

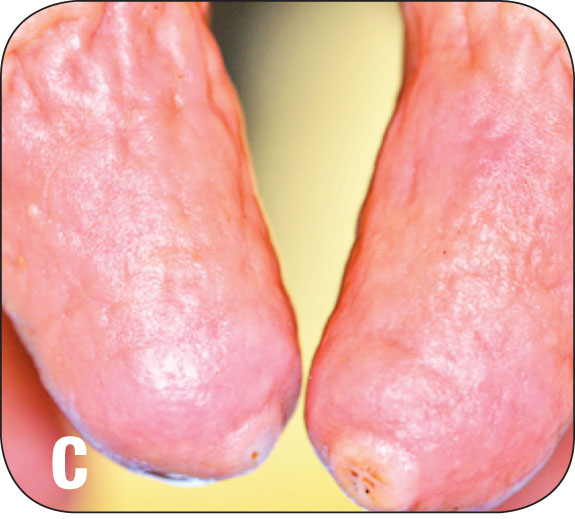

Medium to deep red color indicates increased blood congestion. This can be isolated to the teat end or it can involve the entire teat ( Picture C ).

This level of congestion can lead to deep tissue damage over time.

Extreme congestion can lead to cyanosis in some cases. Cyanosis is a lack of oxygen that causes the skin to turn blue in color.

This can be seen as a faint blue cast over the entire teat barrel or more typically as a blue ring where the inflation mouthpiece has rested during milkout ( Picture D ).

Chronic cyanosis can lead to significant cellular damage or even cellular death from lack of oxygen.

I like to examine teat skin color as cows enter the parlor before any prepping starts, compare that with skin color right before unit attachment and again as soon as the unit is removed.

Chronic congestion produces red teats pre-prep and typically a lot of discomfort and kicking during the prep procedure.

Red or blue teats at unit detach point to issues that are just emerging or are less severe than the previous scenario. The level of discomfort adds important information to this diagnosis.

Cow behavior

This observation is very powerful but very difficult unless you get into other parlors for comparison. The fact remains it is normal for a cow to stand quietly while her teats are cleaned and a milker is attached. It is also normal for her to stand quietly while being machine-milked with minimal stepping or kicking.

This behavior is the one that is most common for the abnormal to become normal. To help dairymen visit other parlors and learn what normal and abnormal behavior looks like without leaving their individual dairies, I have filmed and posted video training clips online.

(These videos will be available at mqiqconsulting.com in the near future.) These videos provide a reference of normal and abnormal milking time behavior that I have observed during my consulting work around the country.

The test I perform in every parlor that gives me a great deal of information is the strip yield. (Examples of strip yield training clips will also be online soon.) With a clean, gloved hand, gently hand-milk each functional quarter as soon as the unit is removed. I do my best to keep milk off my glove.

I always carry a flashlight to examine teat color first and then perform the strip yield. I assess the cow’s reaction as well as the amount of milk.

I perform 15 to 20 strip yield tests before I start to draw any conclusions about a given group or herd. I notice if they are heifers or just-fresh animals.

The question always arises, “How much milk should I get?” Most experts suggest around 4 to 8 ounces (200 ml) evenly distributed from all functional quarters. In my experience, I typically find one of three results.

1. Not enough to put in my coffee! (one squirt or less per quarter)

2. Good (two to four squirts per quarter)

3. Uneven (two to four squirts from two or three quarters; one to two quarters with a lot of milk still present)

Result 1 is too dry, which causes teat-end irritation and long unit-on time, leading to hyperkeratosis. Automatic take-offs must be adjusted to a “wetter” setting or milkers must be trained to remove units more quickly if you do not have automatic takeoffs.

Result 2 is the ideal goal. Herds with these strip yield amounts should exhibit comfortable cows during milking and little resistance to strip yield tests. Teat ends should be mostly smooth in good weather with this type of strip yield and overall parlor throughput should be acceptable to management.

Result 3 is what I am finding in herds running ultra-high claw vacuum levels (greater than 13” Hg up to the highest I have measured at 14.2” Hg) or rotary and parallel parlors where correct unit positioning is difficult to accomplish in general.

Poor alignment can overmilk one or two quarters with excessive pull on the inflation (machine stripping), while leaving milk in the quarter the cup is bending or pinching. The high claw vacuum herds struggle with blood congestion at the base of the teats after two minutes of unit-on time.

Dr. Reinemann at the University of Wisconsin teaches that this congestion starts happening above 12.0” Hg of claw vacuum.

Swelling builds up at the base of the teat (against the udder) where a narrowing naturally occurs at the annular ring ( Picture E ).

The annular ring is not a true sphincter but can affect the passage of milk from the gland cistern to the teat cistern, especially when excessive mouthpiece vacuum leads to blood congestion and subsequent swelling of this tissue. This in turn leads to uneven milkouts from random quarters.

Swelling pressure against this ring can reduce the opening between the udder and the teat, effectively stopping milk flow. The automatic take-off identifies the cessation of milk flow and detaches the unit.

Within a few seconds of unit removal, the swelling and blood congestion starts to subside and the high mouthpiece vacuum is removed, allowing the annular ring to relax and milk flow to resume.

This explains why the strip yield test can find one or two quarters with a lot of milk still in its quarter.

So a fast milkout from high vacuum levels is accomplished by sending milk back to the pen rather than harvesting it for sale.

So raising claw vacuum can initially produce a faster and reasonably complete milkout. But over time, chronic blood congestion and tissue swelling with discomfort leading to cow-assisted takeoffs continues to produce the appearance of a fast milkout for completely different reasons.

Some astute managers have reported a drop in bulk tank milk in only a few weeks after raising claw vacuums to ultra-high levels when no other changes were made.

The bottom line is, using the three simple tests listed above will allow you to listen to your cows and identify if they are being milked comfortably, making them the happiest employees on your team! PD

Thomson provides “intelligence for a quality milk harvest” through his consulting practice based out of Battle Creek, Michigan.

Photos and images courtesy of Roger Thomson.

Roger Thomson

Veterinarian

MQ IQ Consulting

teamman22@aol.com