Some dairies across the country are using larger inclusion mixes due to lack of feed storage options. Still in other cases, some feed companies are proposing larger inclusion grain mixes to their customers.

I saw a sign in a dairy producer’s office last week that read, “If you continue doing your job the same, don’t expect improved results.” We’ve all heard the saying many times, but once in a while we need to look in the mirror and review. Are there other ways to accomplish the job that would be more economical and efficient? This article evaluates how we deliver key ingredients to our animals every day.

The term “base mix” varies widely across dairies, so let’s start with exploring the origination of the term. Base mixes are used to consistently deliver small inclusion ingredients into rations to improve mixing efficiency and reduce shrink. Examples would be vitamin and trace mineral packages, amino acids, ionophores and gut health ingredients which may total less than 1 pound. Additionally, major minerals and buffers are usually included which will add another 2 to 3 pounds. This concentrated base mix is going to be approximately a 3- to 4-pound inclusion per head per day in a milk cow ration. Next, higher-value protein ingredients like blood meal or replacements are included at one-half to 1-pound inclusions for a total of 3.5 to 5 pounds. Adding higher inclusion protein sources like soybean meal, expeller and canola can add another 4 to 6 pounds, which moves the base mix to 7.5 to 11 pounds. Lastly, adding energy sources like supplemental fats and starch ingredients can account for another 10 to 15 pounds, resulting in a 17.5- to 26-pound base mix to the farm.

At the fundamental level (vitamins and trace minerals), we do a base mix to improve mixing consistency and reduce shrink on-farm. But including all of the above ingredients into one base mix may not necessarily be the most economical approach for the dairy. There are many factors to consider when evaluating what a dairy's best base mix size should be. Some factors we need to consider would be:

- Delivery and fuel surcharges

- Mixing fees per ton

- Margins on base mix ingredients

- On-farm storage and return on investment (ROI) of additional storage

- On-farm mixing time – can be offset by on-farm premix every two to three days

- Shrink – does reduced shrink offset the above costs?

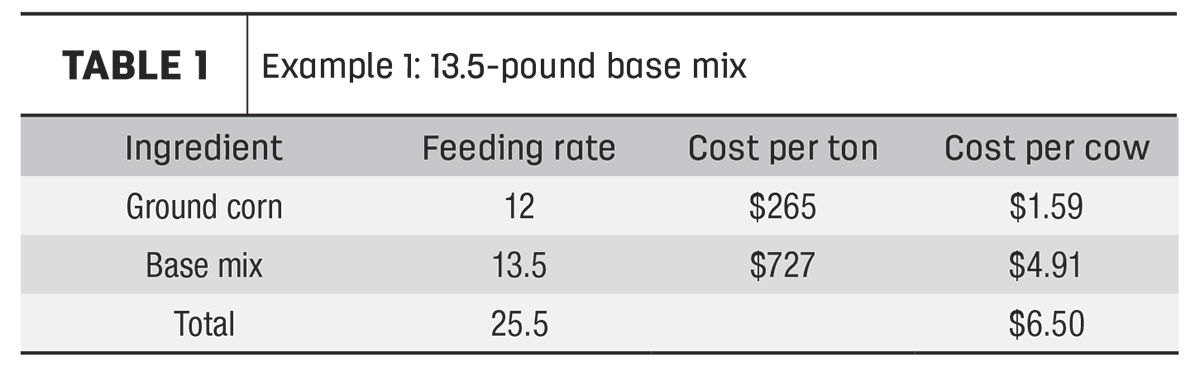

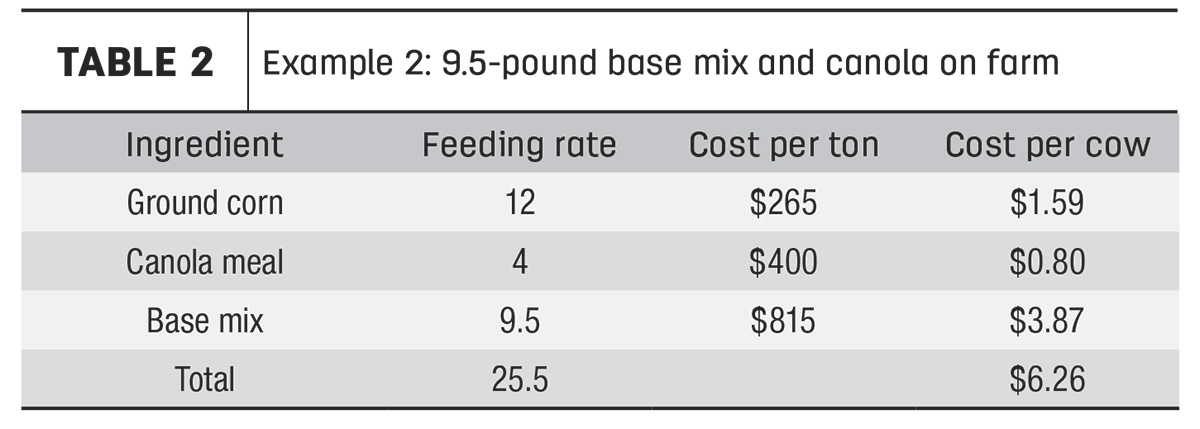

Let’s look at the economics of getting two different-size base mixes of the same diet to the cow.

In Tables 1 and 2, a savings of 24 cents a cow could be captured for the dairy. On a 1,000-cow dairy, that would equate to nearly $90,000 annually, by simply breaking one high-inclusion ingredient out of the base mix. If storage were an issue, the ROI on building or purchasing additional storage could be realized within months.

In these examples, having multiple ingredients broken out of the base mix affords the dairy multiple opportunities. Breaking out more ingredients will only lead to greater economic advantages. As the dairy is able to reduce the size of their base mix, they are able to capture the money that would be spent on mixing fees, fuel surcharges and feed mill margins for each of these ingredients. They can now bid multiple ingredients with various suppliers to gain an even further economic advantage.

Additionally, as the base mix gets reduced in size, it becomes a higher-value nutrient-dense mix. This gives your nutritionist the ability to feed cows more cost-effectively. Rather than having to feed one large base mix to the whole herd with all high-value nutrients going to all cows, the dairy now has the flexibility to reduce costs and focus nutrients into individual groups of cows more efficiently. In example 1, the dairy will have to feed all ingredients in the base mix to all groups of cows. In example 2, the dairy now has the opportunity to be even more cost-effective by focusing different-value nutrients into different stages. The dairy could now consider feeding late-lactation cows a cheaper protein source such as distillers, rather than the more expensive canola meal that the herd in example 1 is feeding to their late-lactation cows because it is locked into their large base mix.

When maximizing profitability, shrink, accuracy and labor need to be considered. To maximize accuracy, dairies should consider making an on-farm premix of non-forage ingredients. This premix could be made as little as two to three times per week. Shrink is reduced since fewer ingredients are needed when mixing individual loads daily. Using example 2 from above, the premix could be made by mixing the canola and ground corn in advance and storing the new commodity mix in another storage structure. This alleviates the potential for error by the feeder adding larger quantities of an ingredient to an individual pen's TMR. Making a premix of ingredients also saves time on daily feeding by reducing the number of trips back and forth to bins. With tight margins on dairies across the country, we need to continually evaluate all options to maximize the opportunity for profits.