A healthy heart is the central system keeping your body alive and functioning properly. The same is true with your milking system. The pulsator acts as the heartbeat of the entire milking system to ensure proper milk harvest.

And just like with your own heart, it’s important to get regular check-ups to verify the pulsation system is running smoothly.

Poorly performing pulsators can and will affect the overall milking performance on your dairy and negatively impact teat condition and cow comfort. Make sure the heartbeat of your milking system is beating strong by considering the following maintenance and evaluation steps.

1. Pulsation settings

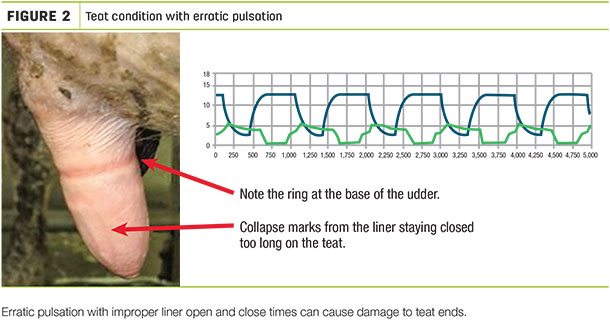

Milk harvest and teat health greatly depend on the pulsation settings, which control an alternating pattern of atmospheric air and vacuum to open and close the teat cup liner. Improper open and close cycles can cause erratic pulsation, resulting in irritation to the teat ends (Figure 2) and a reduction of milk flow.

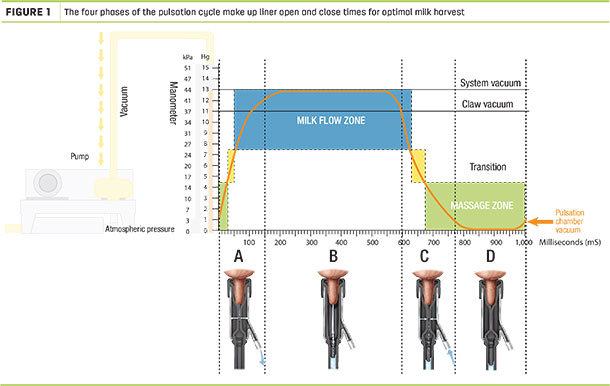

Ensure accurate pulsation settings by graphing pulsators monthly. This will help keep the pulsation settings steady by evaluating the length of the four pulsation phases: A, B, C and D. In general, the A and B phase indicate liner open times, and the C and D phase indicate liner close times (Figure 1).

Click here or on the image above to view it at full size in a new window.

A full pulsation cycle includes the time it takes to rotate through all four pulsation phases and typically takes approximately one second to complete, although this number can vary based on the rate selected.

According to ISO standards, the B phase should be at least 30 percent of the total pulsation cycle, and the D phase should be at least 15 percent. However, most U.S. manufacturers recommend settings much higher to maximize milk flow on today’s higher-producing cows.

Average B phase settings of 450 to 525 milliseconds, and average D phase settings of 200 to 250 milliseconds are also commonly recommended. When evaluating the pulsation settings, you should consult your manufacturer’s recommendations for the brand of equipment and liner used.

2. Rates and ratios

It’s also important to assess the pulsation rate and ratio when graphing the pulsation system. Maintaining an accurate pulsation rate and ratio can provide proper pulsation for optimal open and close times and teat condition.

Like the beats per minute of your heart rate, the pulsation rate calculates the number of complete pulsation cycles per minute. To maintain recommended liner open and close times, the pulsation rate is generally between 52 and 68 cycles per minute and should be consistent from day to day.

The pulsation ratio represents the percentage of open and close time in each pulsation cycle. The default pulsation ratio is oftentimes split between 60 percent open time and 40 percent close time.

Ratios can also be split, giving different ratios to front quarters and rear quarters. However, it is always important to consult with the manufacturer, as recommendations for pulsation rates and ratios can vary based on the type of equipment and liner being used. In addition, equipment should always be fine-tuned by your local milking equipment specialist.

3. Maintenance needs

Just as regular check-ups are essential for a healthy heart, regular maintenance of the pulsation system is necessary to keep the system strong. Maintenance needs are determined based on hours of run time, including pulsator operation during the wash cycle.

Most manufacturers recommend that pulsators should be rebuilt or maintained at 1,500 to 2,000 hours of run time or at least every four to six months.

All pulsators should be rebuilt and maintained at one time, regardless of parlor size, to ensure all pulsators are in sync. It’s also recommended to have regularly maintained replacement pulsators available when a failure is suspected.

4. Complete system evaluation

The pulsation system is more than just the pulsator. Equipment, including the pulsation controller, long-pulse tube, air fork or divider, short air tubes and teat cup assembly (shell and liner) affect the ability of the pulsation system to control the opening and closing of the liner.

Consider these recommendations for ideal performance of the entire pulsation system:

- Keep the length of long-pulse tubes as short as possible. Replace tubes on a routine schedule.

- Check the condition of short air tubes daily for cracks and holes. Replace tubes monthly.

- Maintain fresh air access from fresh air filters, tabs or covers.

- Perform regular cleaning and sanitation of all tubes, shells and liners.

- Evaluate shell size and volume and liner type and condition when determining the correct rates and ratios.

- Check voltage at the controller and first, middle and last pulsator on each system.

Vacuum levels should be consistent among all pulsators. Pulsation settings, vacuum levels and fresh air work in unison to properly open and close the liner for optimal milk flow. Indicators of correct vacuum and pulsation settings include cow comfort during milking, no drastic change in teat coloration, consistent milkout and unit duration.

Keep the heart of your milking system going strong with regular pulsation maintenance and evaluation. Don’t hesitate to ask your milking equipment dealer questions to ensure those doing this type of testing fully understand proper pulsation function, and be sure they follow manufacturers’ recommendations.

By doing so, you can benefit from continued optimal equipment performance, milking after milking. ![]()

-

Mark Walker

- Liner and Supplies Sales Specialist

- GEA

- Email Mark Walker